Retrofit spindles from EMAG: Full performance - maximum stability

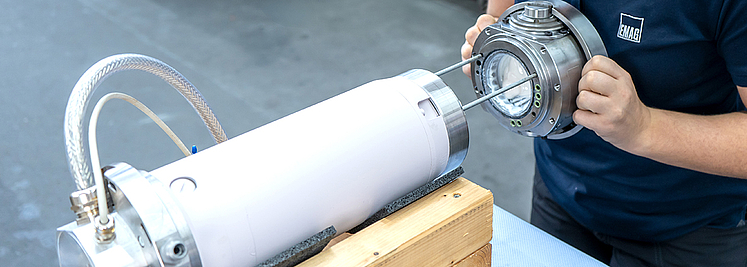

EMAG offers a comprehensive service for used machine spindles. This ranges from a flexible repair program with various options to precision testing prior to commissioning. Many spindle types are available in the EMAG warehouse for quick replacement.

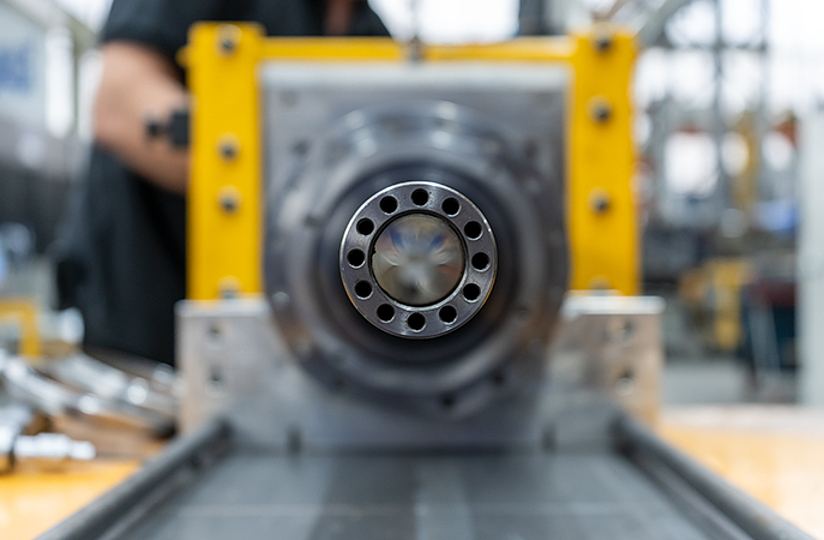

The spindle - an indispensable component of machining quality

Many EMAG machines have so-called pick-up spindles: The spindle picks up the component from the automation (shuttle, belt, etc.) and guides it into the work area, where machining starts - with speed and precision. This assembly is critical to guaranteeing machining quality and is subject to a certain amount of wear.

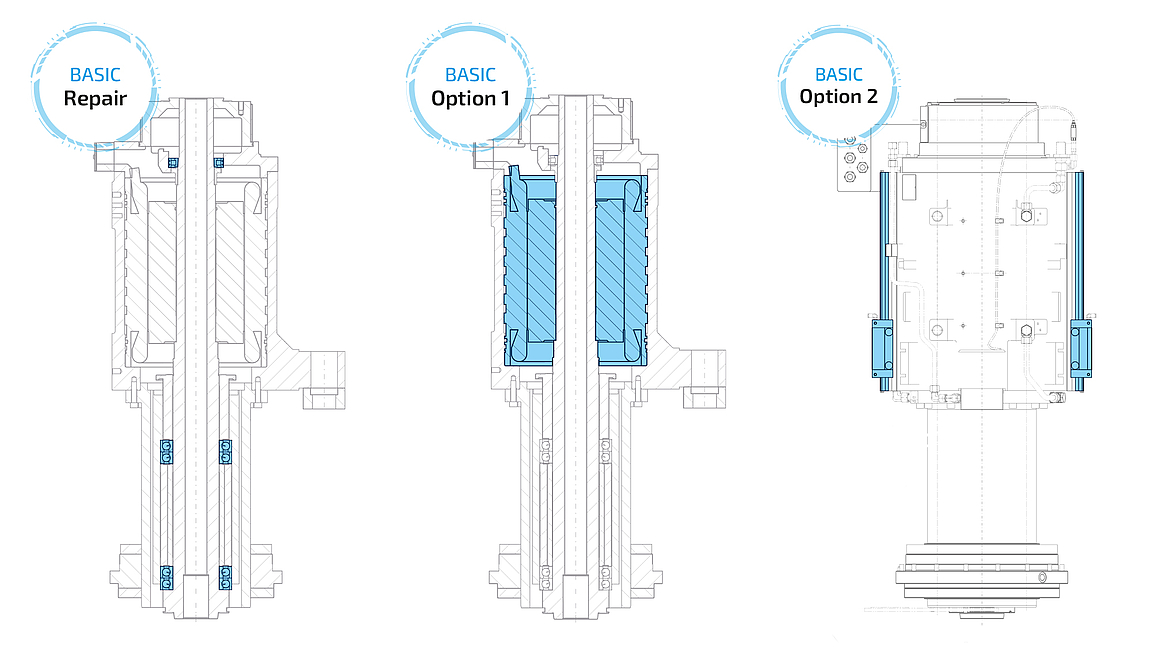

Repair program with options

In this context, the "Spindle Assembly" area within EMAG Retrofit is particularly important. Among other things, it offers a comprehensive repair program for customers' own spindles, using only new parts or reconditioned components in original quality. You can choose between the “Basic Repair” or “Full Repair” service packages.

Basic Repair

- Cleaning the spindle unit

- Replacing the bearings

- Replacing the seals

- Test bench run

Basic Option 1

- Engine overhaul

- Test bench run

Basic Option 2

- Replacement of the linear unit (Z-axis)

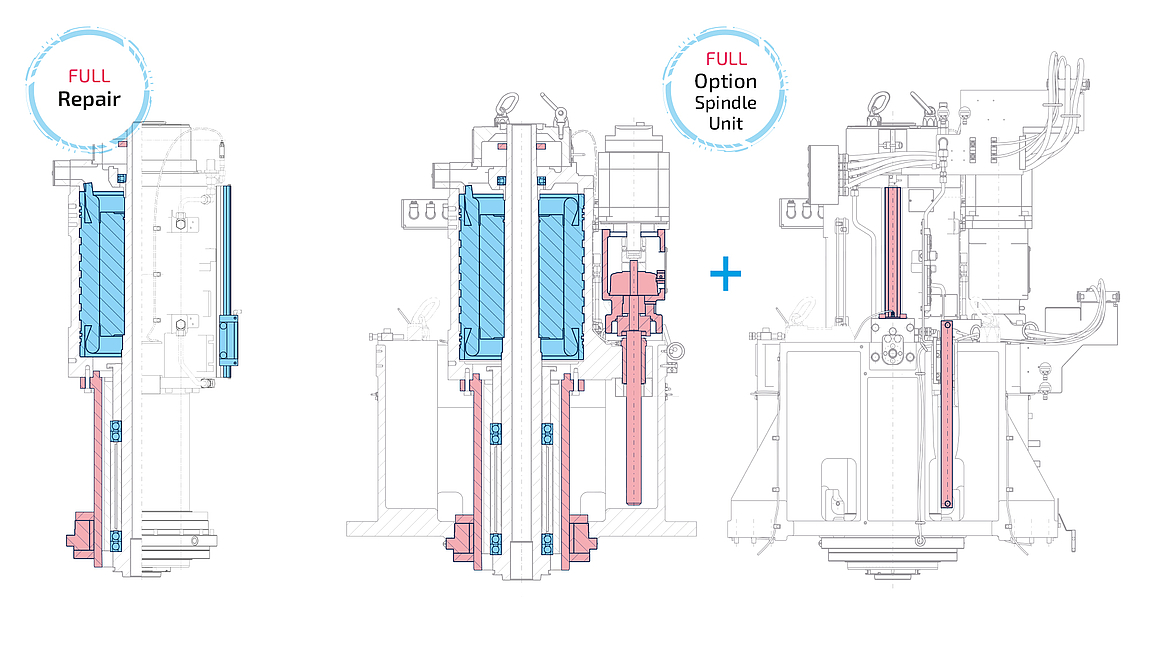

Full Repair

- Cleaning of the spindle unit

- Replacement of bearings

- Replacement of seals

- Repair of hydrostatic bearings

- Engine overhaul

- Replacement of rotary encoder

- Replacement of linear unit (Z-axis)

- Test stand run

Full Option Spindle Unit

- Cleaning of the spindle head

- Repair of the feed drive (Z-axis)

- Replacement of the length measurement system (Z-axis)

- Replacement of the hydrostatic components

- Restoration of the geometry

Your advantages by “Basic Repair” and “Full Repair” service packages:

- Flexible, transparent and cost-optimized

- “Fast Lane” processing possible

- EMAG support during disassembly/assembly and recommissioning

- Perfectly overhauled spindle including extensive testing (concentricity, tightness, test stand run, etc.)

- 12-month manufacturer's warranty for reliable production

Comprehensive audit

Subsequently, a recorded initial commissioning at EMAG - before delivery to the customer - ensures maximum quality and process reliability. The grease distribution run within the spindle is checked and a precision run-in cycle and endurance run are carried out in accordance with EMAG standards. The result equals the quality of a new spindle.

Replacement spindles from stock

In addition, EMAG guarantees its customers a high speed, for example in emergencies after a collision. As a result, the assembly must be replaced quickly to avoid long downtimes. For this purpose, EMAG has a central spare parts warehouse that stocks many standard assemblies such as main spindles and turret units.

Advantages

|

Technical Hotline

Our technical hotline records all inquiries and gives you technical assistance

+49 7162 17-4300

service.salach@emag.com