Machining Centers & Milling Machines

VSC 315 KBU

- Workpiece length, max.: mm/in 280/11*

- Workpiece dia., max.: mm/in 160/6,5*

- Ball diameter max.: 30 mm | 1 in

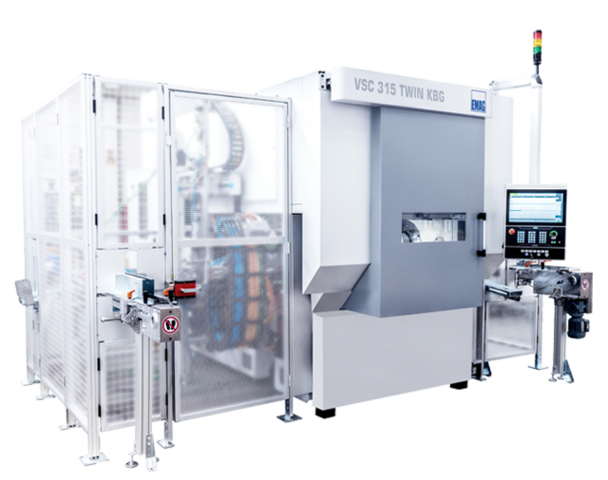

Vertical single spindle ball nose milling and turning center - VSC 315 KBU

The EMAG VSC 315 KBU is a vertical single-spindle ball track milling and turning center for machining ball tracks in joint housings (axle journals, joint rings) and hubs (joint hubs).

complete-machining in a single setup

The machine has one milling spindle (hard machining only) or two milling spindles (for soft machining) mounted on an NC swivel unit (B axis), driven by a torque motor; the swivel angle here is -30° to +90°. The use of turning tools is also possible. The machine is designed with a large Y-axis stroke and a total of three axes (X, Y, Z). High rapid traverse speeds ensure short non-productive times both during workpiece changeover and when approaching the optional measuring probe.

The spindle unit is equipped with a maintenance-free AC synchronous spindle motor. This is characterized by its high dynamics. A triple-bearing spindle with optimized bearing distances and precision shoulder bearings in a tandem-O arrangement ensures high rigidity. The hydrostatic bearing of the spindle quill also guarantees very good damping, excellent guide quality and rigidity with minimal friction. Constant accuracy is ensured by the thermosymmetrical machine design and the integrated cooling system.

The machine base body is made of Mineralit® (reaction resin concrete). This material offers excellent thermal stability and vibration damping effects that are 6 to 8 times better than cast iron. The large spacing of the preloaded linear roller guides in the X-axis ensures high precision at high feed rates and cutting forces. The guides are located outside the work area, so no additional covers are required.

The user is supported in setting up and operating the machine via technology screens. Depending on the machine type, a variety of basic and monitoring functions are available. For fast programming of specific ball track shapes, the machine can be equipped with workshop-oriented programming modules.

Workpieces

The Right Manufacturing Solution for Every Workpiece

Machines for your requirements

(2) machines found

Technical Data

Workpiece length, max.

280/11* mm/in

Workpiece dia., max.

160/6,5* mm/in

Ball diameter max.

30 mm

1 in

| Workpiece length, max. | mm/in | 280/11* |

| Workpiece dia., max. | mm/in | 160/6,5* |

| Ball diameter max. |

mm

in |

30

1 |

| Chuck dia., max. |

mm

in |

254

10 |

| Swing diameter |

mm

in |

260

10 |