Machining Centers & Milling Machines

HCM 110

- Workpiece dia., max.: 110 mm | 4.5 in

- Workpiece diameter, min.: 30 mm | 1 in

- Workpiece height, min.: 15 mm | 0.5 in

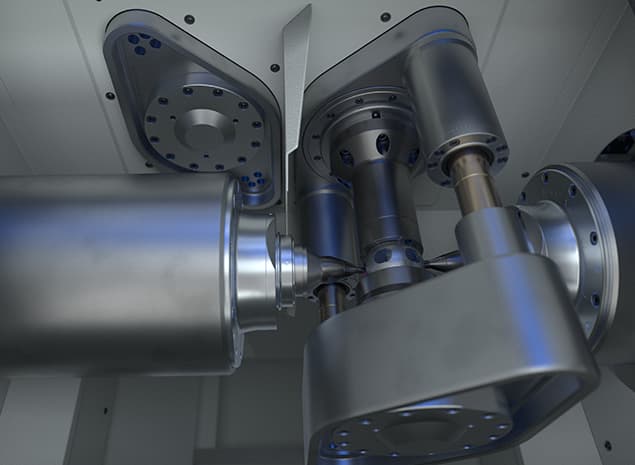

HCM 110 – dual spindle milling machine for ball cage milling

The HCM 110 is a dual spindle milling machine for ball cage milling. The machine is designed for both soft and hard milling. Owing to its high precision, this milling machine from EMAG can entirely replace the grinding process for ball cages.

Flexible manufacturing concept for all cage types

Due to old legacy machinery, many ball bearing cages for CV joints are still manufactured today using a grinding process. However, a worldwide trend can be observed which is gradually replacing the grinding process with other more efficient technologies to save ancillary production costs.

In the conventional grinding process, there are sometimes as many spindles as required by the number of windows in the ball bearing cage. This does not allow for flexible retooling from six to eight windows, for example.

With its HCM 110 dual spindle milling machine, EMAG is now offering a flexible manufacturing concept for all cage types that allows for significant cuts to running costs, when compared to manufacturing with grinding processes.

Hard and soft milling with the same machine configuration

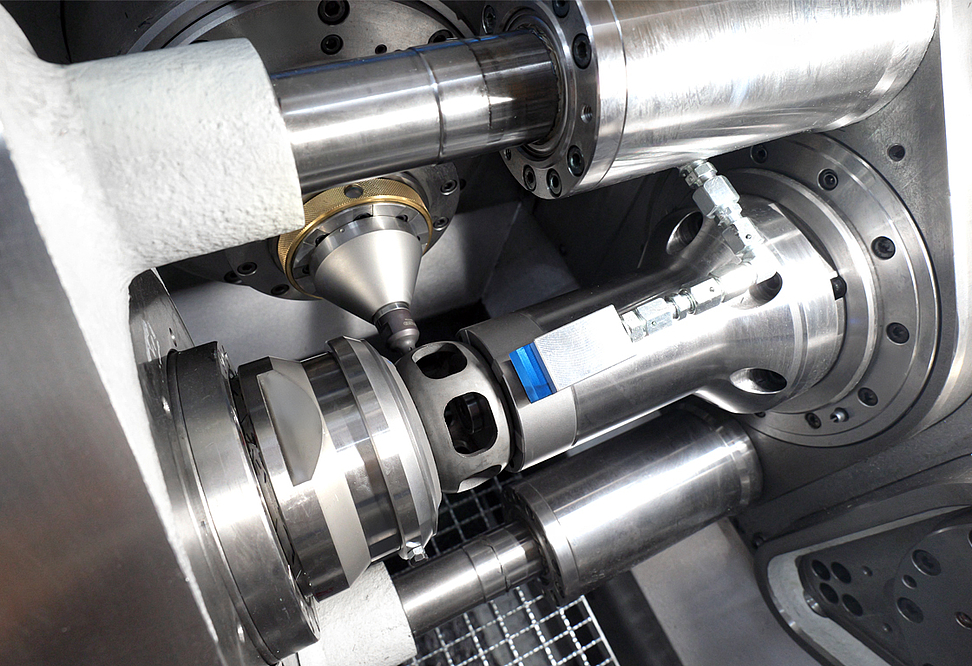

The HCM 110 milling machine is a dual spindle machine that is specially tailored for the needs of ball bearing cages. The machine produces a high output using the pendulum or DUO principle. Ball bearing cages can be hard or soft milled as required. The process can also be performed dry, with coolant, or with minimal quantity lubrication.

Pendulum principle for the shortest cycle times

With the pendulum principle, both milling spindles always machine a cage simultaneously. This is done alternately on one tool spindle and then on the other. While milling is done on one tool spindle, the other is loaded and unloaded outside the machining area. The pendulum principle thus is the machining method with the shortest cycle time.

With the DUO principle, the left milling spindle only machines the cage on the left workpiece spindle and the right milling spindle only machines the cage on the right workpiece spindle.

A third operating mode is required for cages that have two different window shapes and therefore must be machined with two different tools. That is then referred to as an OP 10/20 operation.

A robot that is fully integrated in the machine ensures the highest possible speed when handling the components.

Advantages HCM 110

- Hard and soft milling with the same machine configuration

- Modern, flexible, and high-output machine concept

- Lower running costs compared to grinding applications

- Three different operating modes that can be adapted to the customer’s needs

- Shortest cycle times

- Enhance your technological expertise at EMAG

- Worldwide service network with specialists in the area of cardan shafts

Technical Data

Workpiece dia., max.

110 mm

4.5 in

Workpiece diameter, min.

30 mm

1 in

Workpiece height, min.

15 mm

0.5 in

| Workpiece dia., max. |

mm

in |

110

4.5 |

| Workpiece diameter, min. |

mm

in |

30

1 |

| Workpiece height, min. |

mm

in |

15

0.5 |