Vertical Turning and Grinding Centers, Chucked Components

VSC DS / DDS

- Chuck dia., max.: 250 / 400 mm | 10 / 15.5 in

- Swing diameter: 250 / 420 mm | 10 / 16.5 in

- X-axis travel: 685 / 850 mm | 27 / 33.5 in

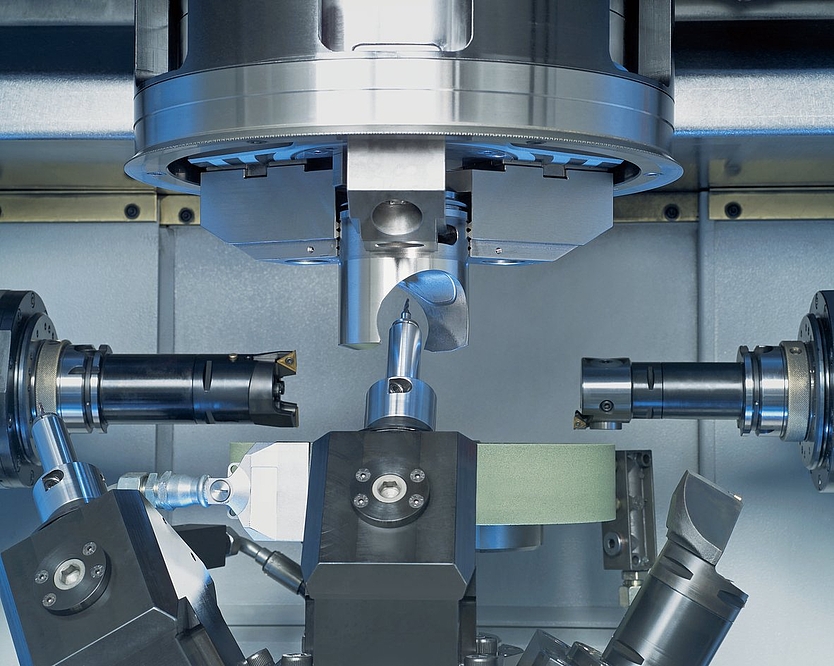

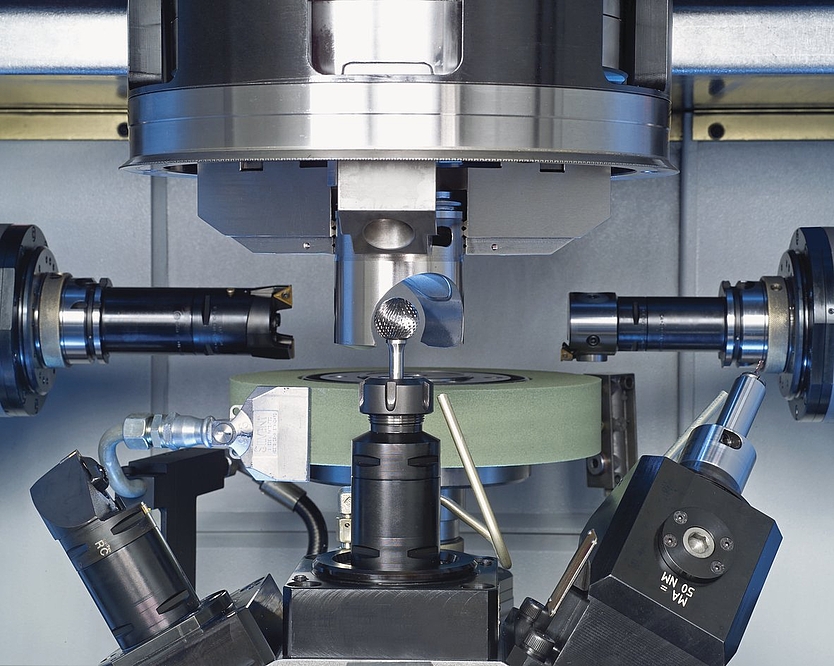

Vertical turning and grinding center: Hard turning, scroll-free turning, grinding.

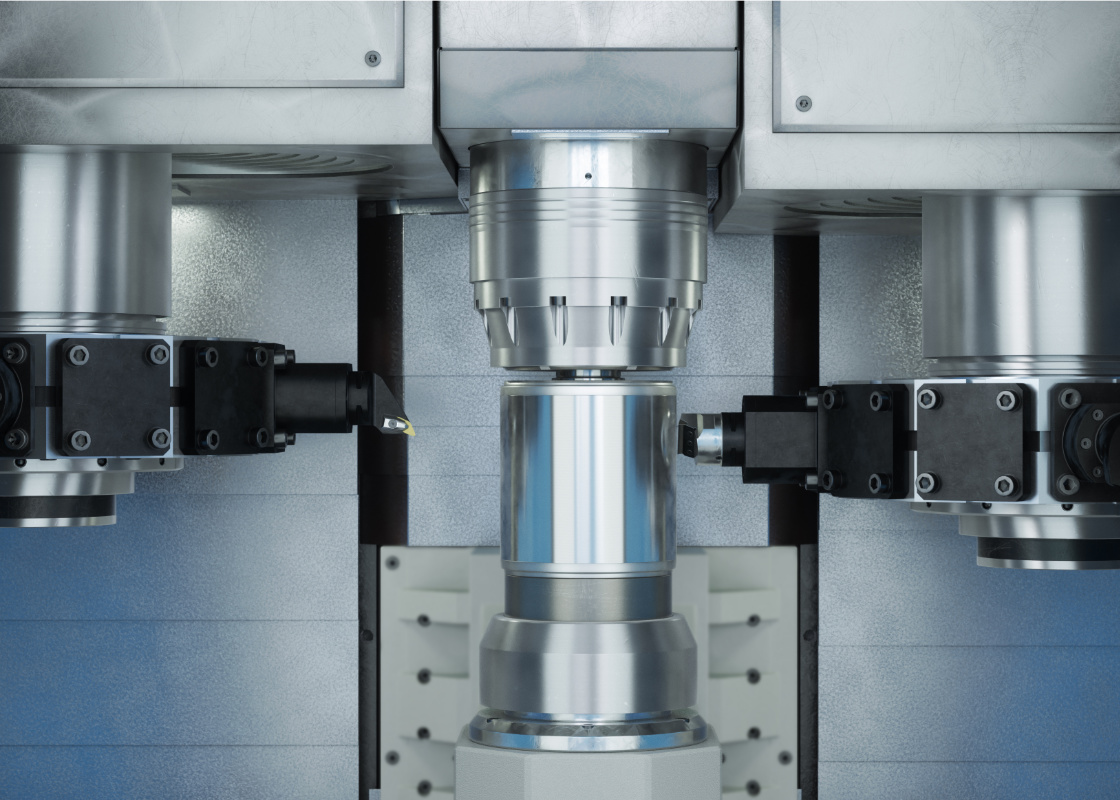

Vertical turning and grinding – a solution that has it all. The combined turning and grinding centers VSC 250 DS, VSC 400 DS and VSC 400 DDS combine the advantages of vertical hard turning with the advantages of grinding, on a single machine, in a single set-up.

Depending on production requirements the turning and grinding center VSC DS can be equipped with turning, milling, drilling, grinding and even honing or hardening modules. It could also use combinations of them, of course. For each requirement the best possible technology is available.

Complete production processes with the turning and grinding center VSC DS

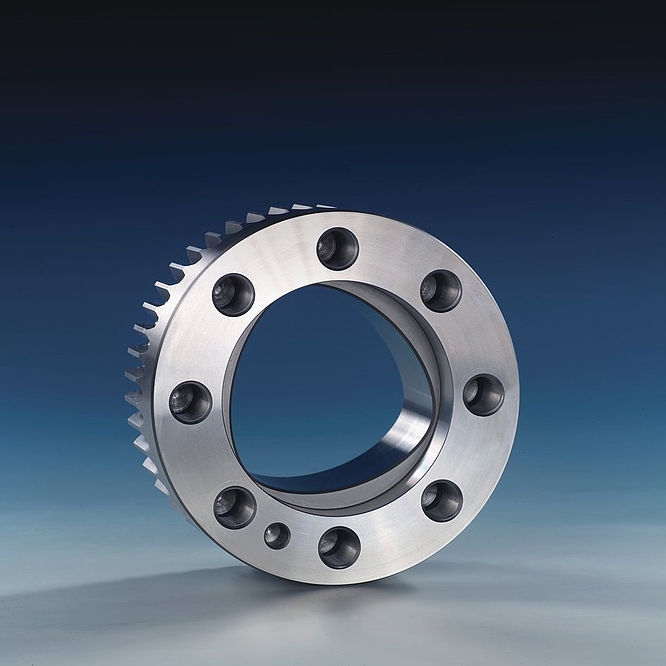

The turning and grinding center VSC DS is specifically designed for the low-cost, process capable, precision machining of medium to large component batches. Typical examples of such workpieces are: gearwheels, chain wheels, sliding sleeves, parts for CVTs, link pins, conrods, rocker arms, bearing rings and piston rings.

In each case, workpiece and quality requirements decide which of the available machining processes is the best and the most economical. The advantage for the customer is in the flexibility that allows them to select the best technology for every application: hard turning, scroll-free turning and grinding, all on a single machine.

As on all machines of the VSC series, the pick-up principle ensures that the EMAG REINECKER VSC DS turning and grinding center loads itself. There is consequently no need for cost-intensive, space-devouring gantry loaders or other loading devices that necessitate time consuming resetting work.

Advantages VSC DS / DDS

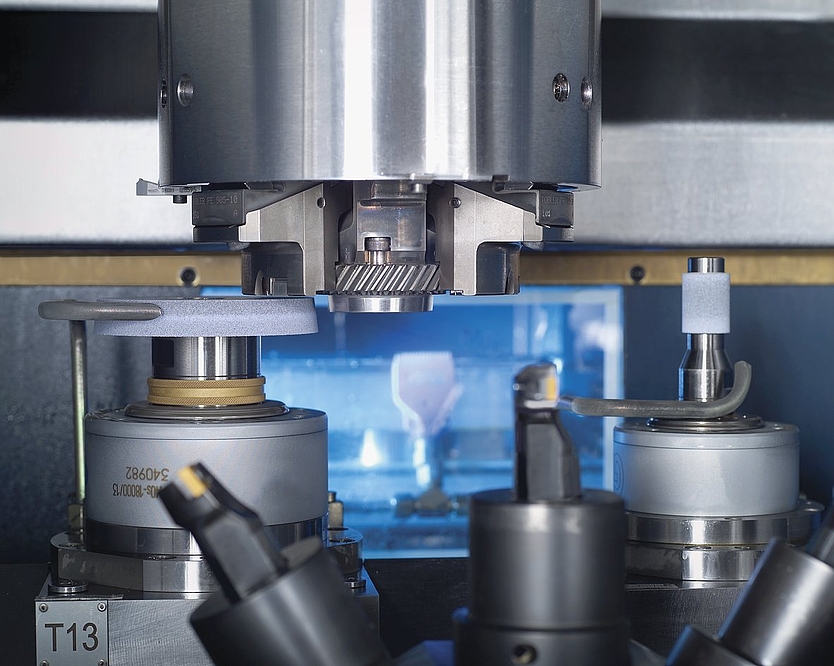

- Vertical hard turning and finish-grinding in a single setup, on a single machine

- All workpiece sections that can be turned with the required process reliability are hard finish-turned and only ground (after hard pre-turning) where component quality and process reliability demand

- A better quality component and increased productivity levels, because the workpiece is machined in a single setup, and the hard turning process leaves a small amount of material to be ground away in the subsequent operation

- The grinding wheel subjected to less wear because it does not need to remove as much stock. This reduces the frequency of dressing operations and offers advantages in cycle time

- The grinding operation has to remove only a small amount of material, the grinding wheel specification can be chosen to reflect the desired finish-machining quality

- Back faces are difficult to reach with grinding wheels; however, this problem is solved by employing hard turning operations

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Technical Data

Chuck dia., max.

250 / 400 mm

10 / 15.5 in

Swing diameter

250 / 420 mm

10 / 16.5 in

X-axis travel

685 / 850 mm

27 / 33.5 in

| Chuck dia., max. |

mm

in |

250

/ 400

10 / 15.5 |

| Swing diameter |

mm

in |

250

/ 420

10 / 16.5 |

| X-axis travel |

mm

in |

685

/ 850

27 / 33.5 |