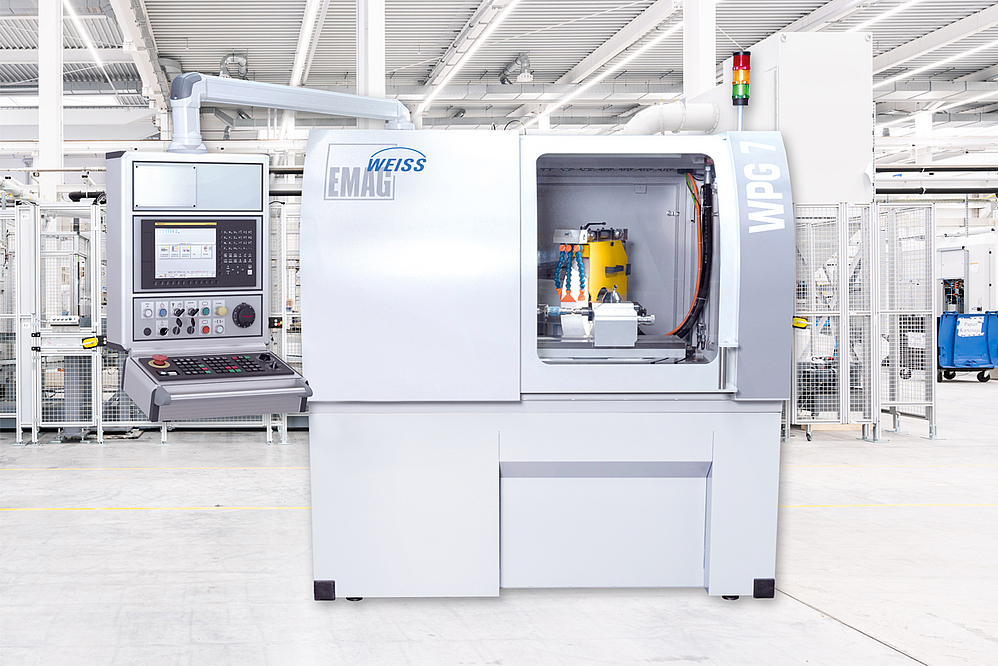

Universal Cylindrical Grinding Machines

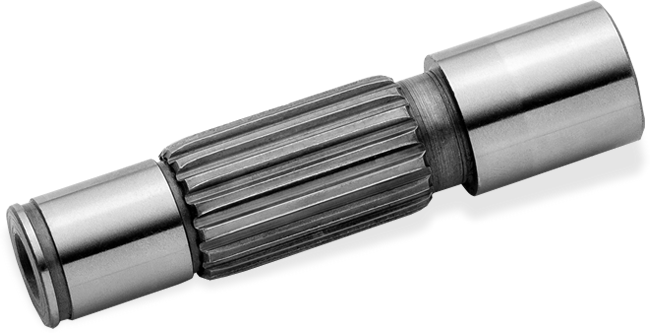

WPG 7

- Workpiece length, max.: 250 mm | 10 in

- Center height: 100 mm | 4 in

- Center length: 380 mm | 15 in

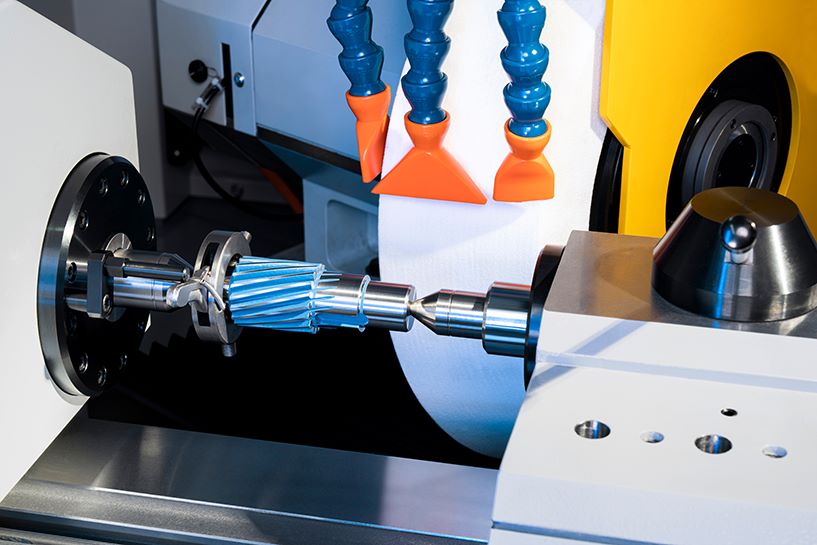

Optimized for Small Shafts, Pinions and Beyond

Achieve unmatched precision in OD cylindrical grinding with the WPG 7 from EMAG. Designed for efficiency and accuracy, this compact machine delivers exceptional results for a variety of applications, all while occupying minimal floor space.

Optimized for Small Shafts, Pinions and Beyond

Looking for a high-performance solution for grinding small shafts or pinions up to a workpiece of 250mm in length? The WPG 7 is you go-to cylindrical grinding machine. With advanced features like a powerful grinding wheel drive, a large grinding wheel, and user-friendly Fanuc control system, this machine offers unmatched precision on the micron range and optional automation.

Discover how the WPG 7 from EMAG can revolutionize your grinding operations with its precise performance and compact design.

- Space-Saving Design: Ideal for manufacturers needing a minimal footprint without sacrificing performance.

- High-Tech Components: Ensures consistent accuracy and reliability for demanding applications.

- Powerful Grinding Wheel Drive: Handles tough materials with ease for faster cycle times.

- Flexible Automation Options: Enhance productivity with tailored automation solutions.

Optimize Grinding for Any Workpiece

The WPG 7 OD grinding machine is the perfect solution for manufacturers seeking a compact, precise and efficient machine for small shafts, pinions and more. Designed to maximize output while minimizing space and setup time, the WPG 7 is ready to elevate your grinding processes.

6 Reasons to Choose the WPG 7

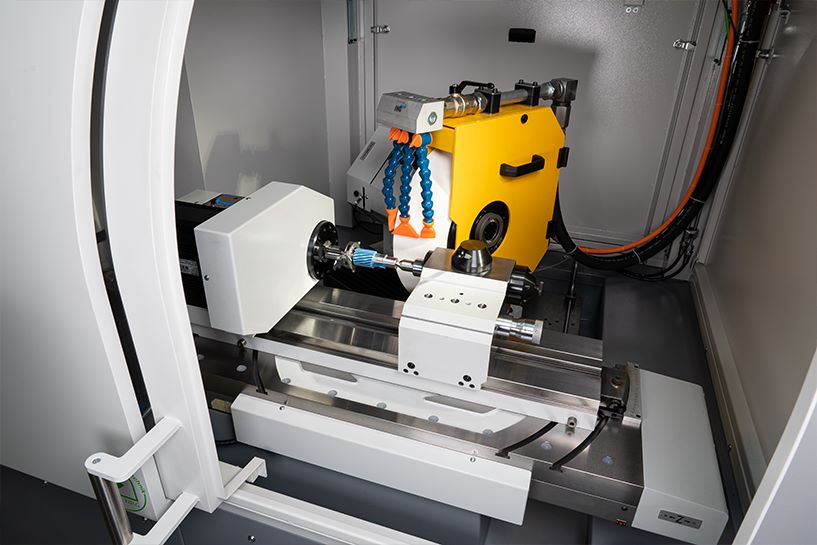

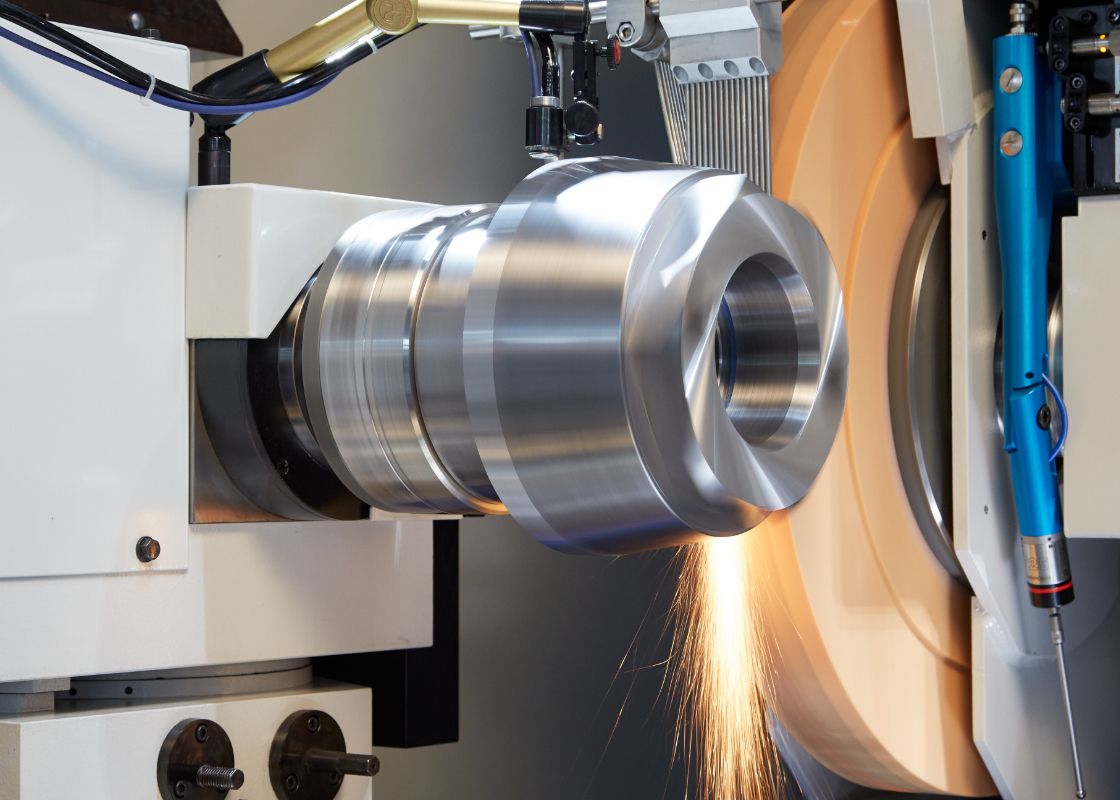

1. Precision and Process Reliability

The WPG 7 ensures consistent, high-quality results with its rigid design that eliminates disruptive vibrations and optimally manages heat transfer. Key precision features include:

- High-precision in-process measurement for real-time adjustments.

- Passive longitudinal positioning for stable workpiece placement.

- Automatic balancing system for reduced downtime.

- GAP and crash control to protect the machine during operation.

2. Speed and Versatility

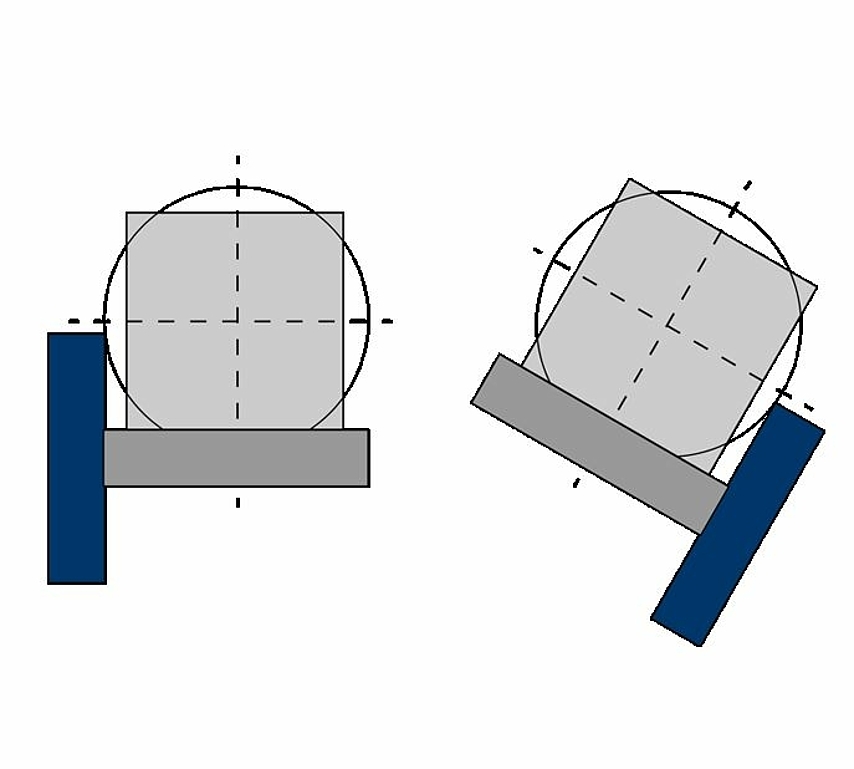

Choose between two configurations:

- Straight Grinding (0°)

- Angular Plunge Grinding (30°)

With a powerful grinding wheel drive capable of speeds up to 50m/s, and a grinding wheel diameter of up to 500 mm (CBN or corundum), the WPG 7 excels in fast, efficient operations.

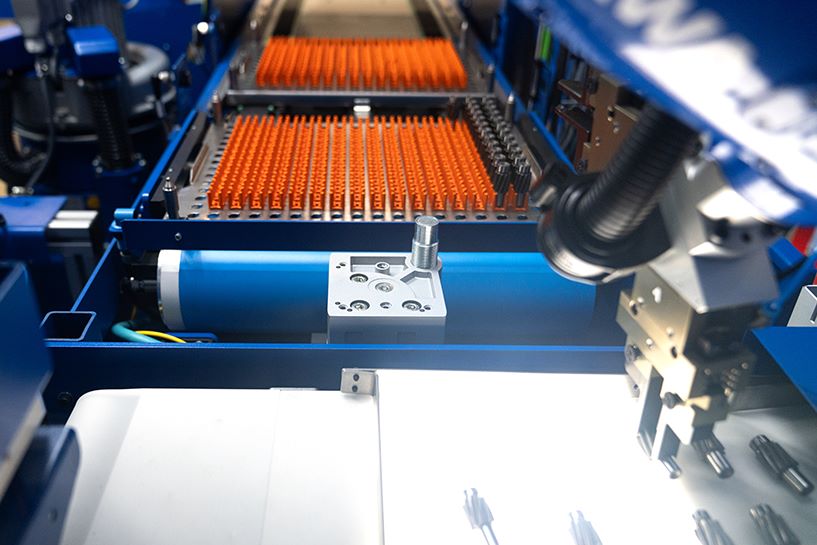

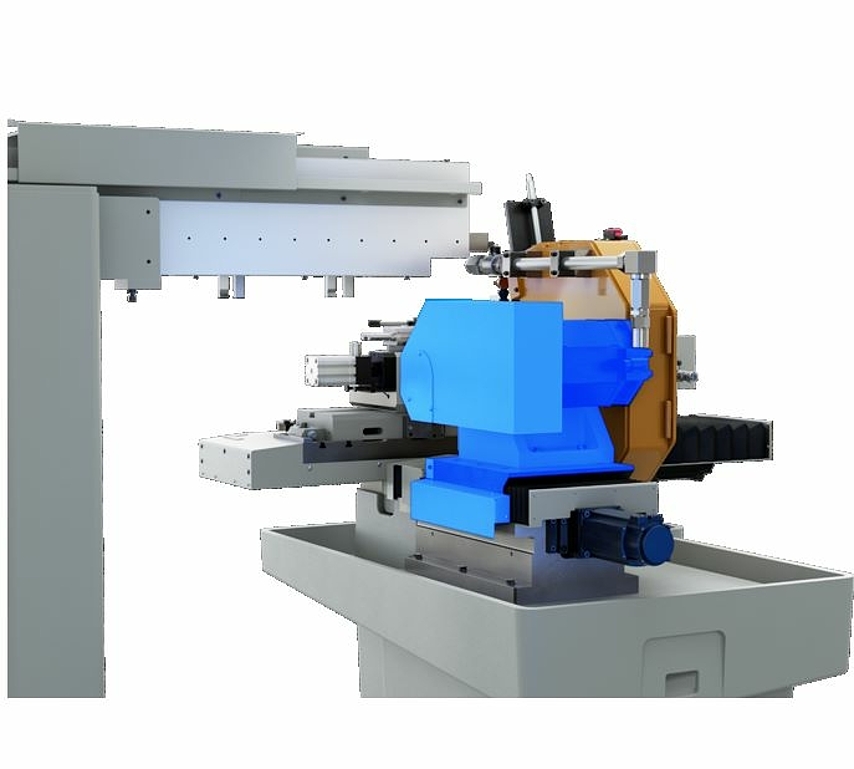

3. Automation for Maximum Efficiency

The WPG 7 supports both manual and automated loading systems. It integrates seamlessly with:

- Chain conveyors

- Pallet circulation systems

- Robot automation

Thanks to an integrated loader and short travel distances, workpiece changeover times are minimized, keeping your production line running smoothly.

4. Simple and User-Friendly Controls

The machine’s Fanuc CNC control (Oi-D series) simplifies grinding cycle programming. Operators can input a minimal number of parameters to achieve the desired grinding cycle, with all common grinding cycles preloaded in the control system.

5. Compact Design for Space Optimization

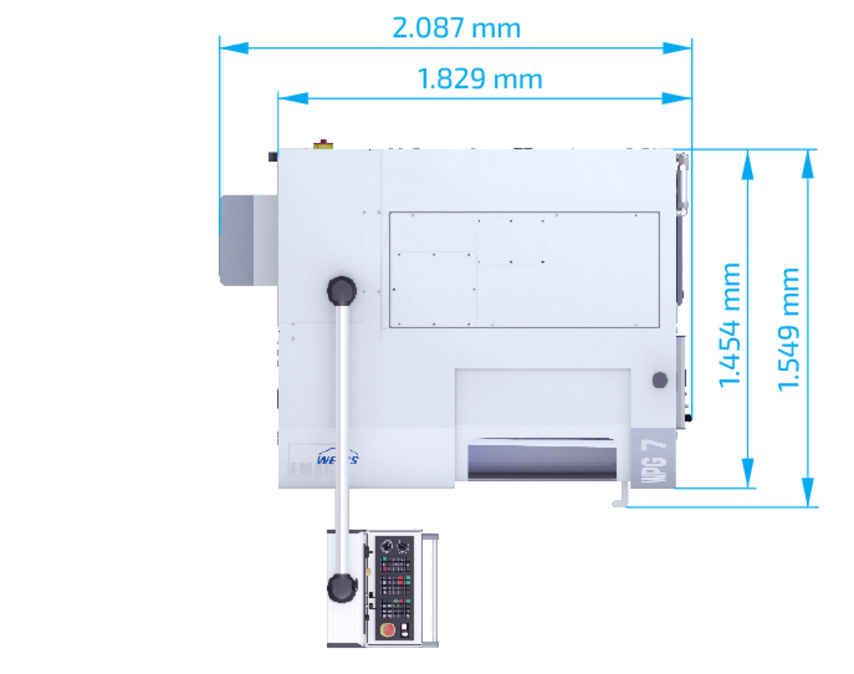

Say goodbye to oversized grinding machines! The WPG 7 occupies just 1.8 x 2.4 meters – making it one of the most space-efficient solutions in its class. This includes the electrical cabinet, lubrication and cooling systems – all in under four-square meters.

6. Fast and Easy Setup

Transportation and setup are hassle-free. The machine fits on two Euro pallets and can be installed in under four hours. Once on-site, it only requires power and compressed air to get started – no complex adjustments needed.

Advantages WPG 7

- Available in 0° straight and 30° angled configurations

- High-speed grinding wheel drive (up to 50 m/s)

- Wheel spindle power: 14kW

- Large grinding wheel diameter: max. 500 x 80 mm

- Compatible with CBN or corundum wheels

- Fanuc CNC control with preloaded grinding cycles

- Advanced cooling system (water or oil options)

- Compact footprint for efficient use of floor space

- With stationary and moving tip MK4

- Optional precision tools: in-process measurement, longitudinal positioning, automatic balancing system, GAP / crash control

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…

Visit the EMAG Blog for more Information

Choosing the Right Universal Grinder: What to Look For

In our article we present to you a practical guide to precision, productivity, and performance in modern manufacturing.