Skiving Machines

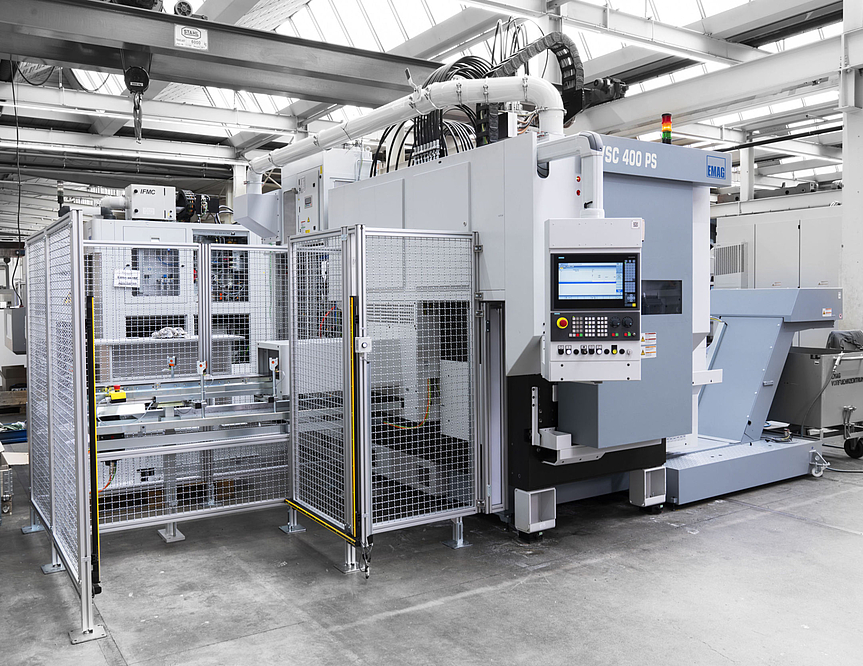

VSC 400 PS

- Workpiece dia., max.: 340 mm | 13.5 in

- Workpiece height, max.: 420 mm | 16.5 in

- Chuck dia., max.: 315 / 400 mm | 12.5 / 15.5 in

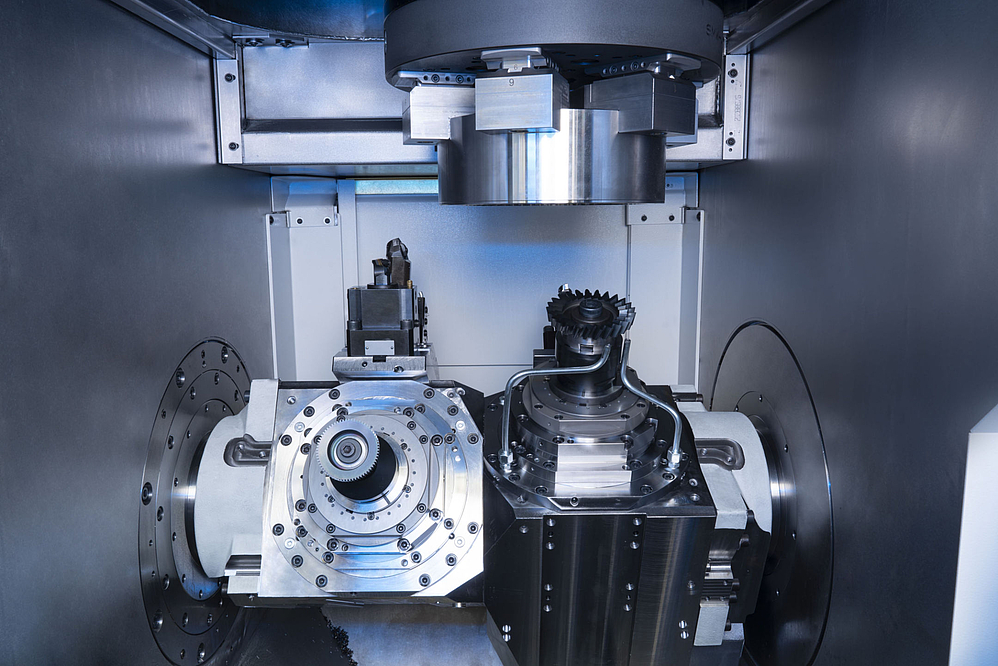

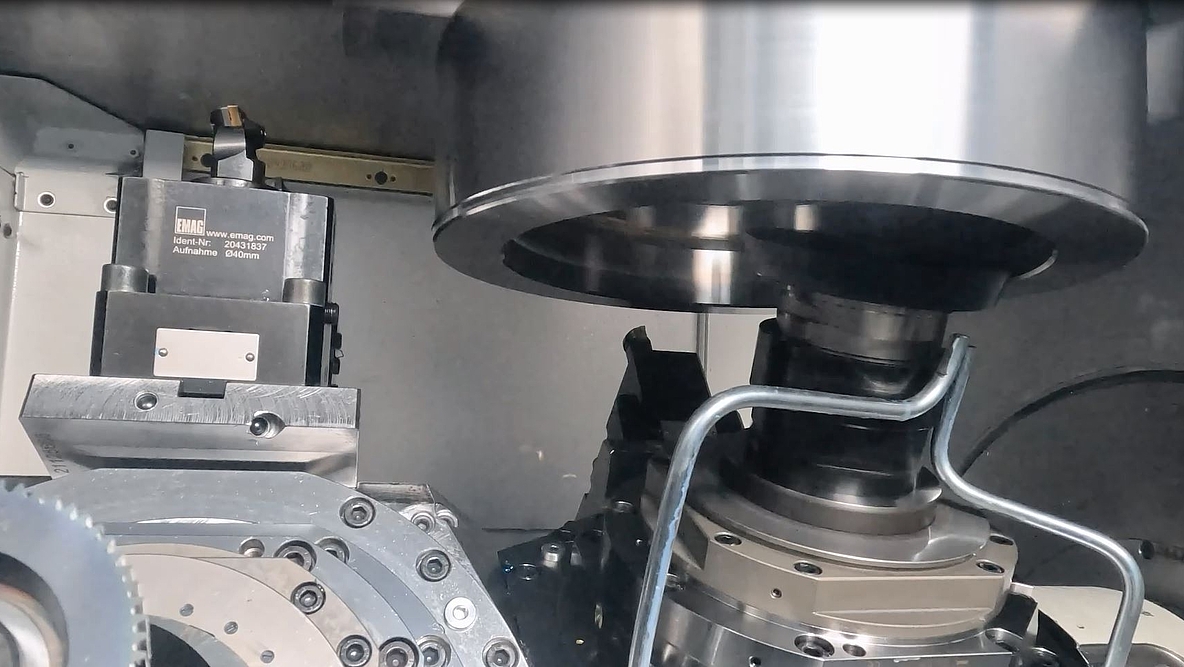

VSC 400 PS Skiving Machine: Perfect Combination of Power Skiving and Turning

Fast, precise, and easy to operate: power skiving has been turned into a highly efficient process for the production of internal and external gear teeth by the VSC 400 PS machine.

VSC 400 PS Skiving Machine

Responsible for this is a high-performance tool concept. The VSC 400 PS can accommodate up to four different power skiving tools on two spindles, plus up to six turning tools. This enables various combination processes with a single clamping operation:

1st variant: Roughing (for example with an indexable insert tool) and finishing (for example with a carbide tool) take place in rapid alternation.

2nd variant: Up to four different types of external and internal gear teeth are produced with four tools.

3rd variant: The combination of pre-turning and power skiving ensures speed and precision in concentricity.

Simple operations ensure productivity with power skiving

Furthermore the intuitive operator interface of the skiving machine, which simplifies the work of the operator considerably, is of great significance. All the operator has to do is input the desired gear teeth values of the component, the values of the tool data sheet, and the cutting values. The machine does the rest. It independently calculates the entire machining program for the power skiving process.

EMAG skiving machine excels in terms of quality

And, in addition, direct drives in the main and milling spindles keep the axes perfectly synchronized during power skiving. And the very stiffly designed B-axis enables a large variety of axis crossing angles – the setting angles of the tool for power skiving. Usually, a value of between 15 and 25 degrees is used here, but EMAG has already implemented power skiving processes with an angle of about 45 degrees in the past.

Advantages VSC 400 PS

- Up to four power skiving tools and up to six turning tools – for numerous combination processes

- Several processes enabled in a single clamping operation for improved component quality (positional tolerances)

- The teeth are deburred in the same clamping operation

- Stiff (high-performance) B-axis for variable axis crossing angles

- Hydrostatic guidance along the Z-axis for maximum vibration damping

- Closed power flow ensures extremely precise workpieces

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Power Skiving allows highly efficient machining of chucked parts and gears. For the machining of internal teeth hobbing, it provides an alternative to…

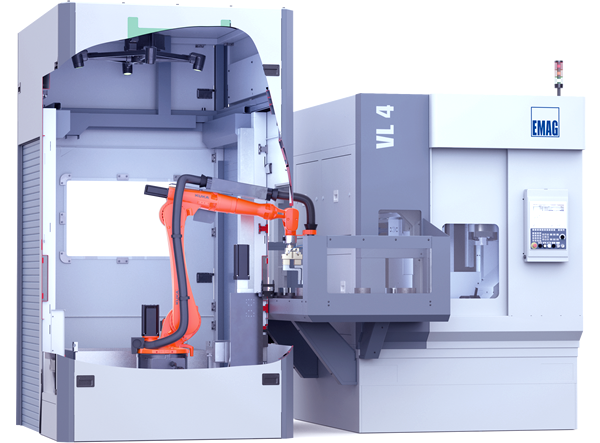

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Industry 4.0

Technical Data

Workpiece dia., max.

340 mm

13.5 in

Workpiece height, max.

420 mm

16.5 in

Chuck dia., max.

315 / 400 mm

12.5 / 15.5 in

| Workpiece dia., max. |

mm

in |

340

13.5 |

| Workpiece height, max. |

mm

in |

420

16.5 |