Horizontal Gear Hobbing Machines

HLC 150 H

- Module range: mm 0.3 - 3.0

- Workpiece dia., max.: 150 mm | 6 in

- Workpiece length, max.: 500 mm | 19.5 in

Horizontal Gear Hobbing and Worm Milling Machine HLC 150 H leads to more flexibility and reduced machining cost

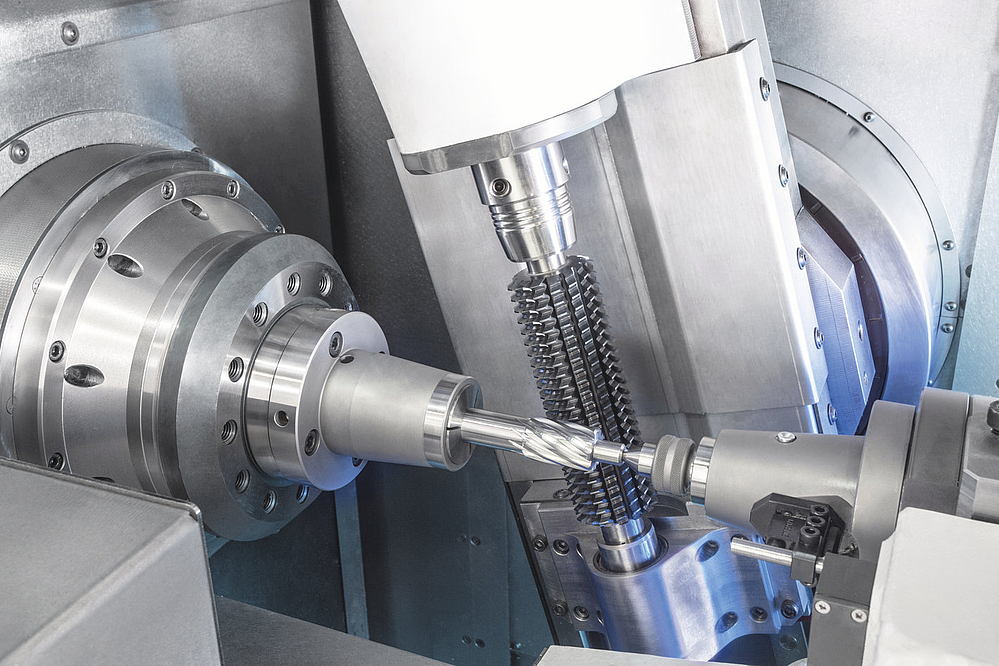

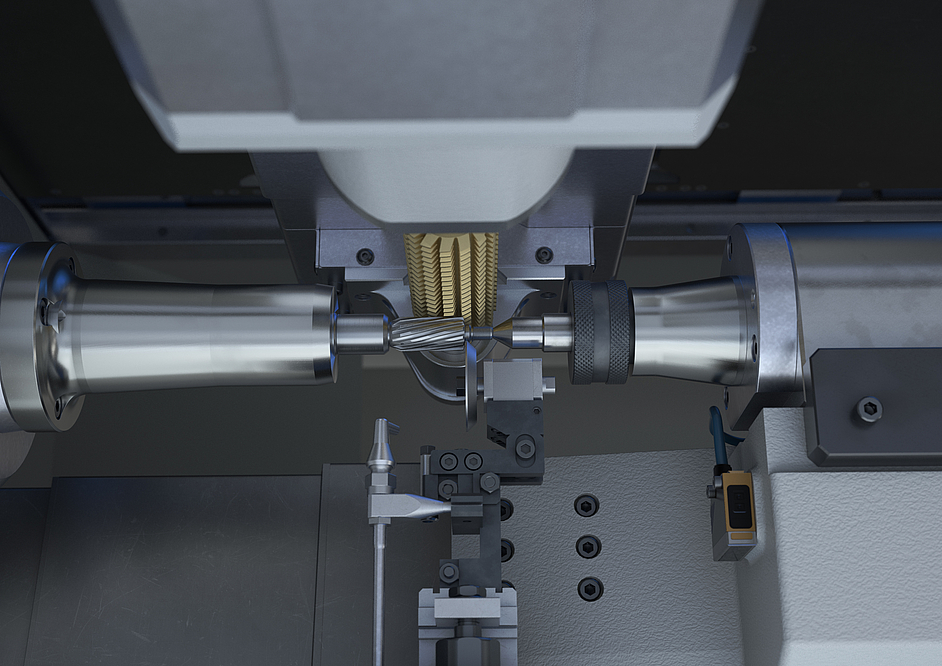

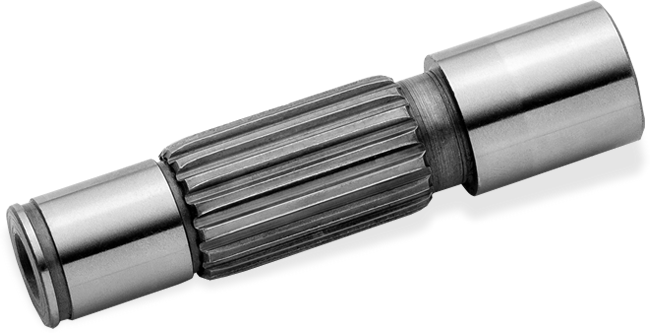

The HLC 150 H is a gear hobbing and worm milling machine with outstanding versatility and flexibility. This high-performance gear machining center caters to a very wide workpiece range: From gears and pinions for gearboxes over armature shafts and worms up to transmission shafts with total length of up to 500 mm (20 in).

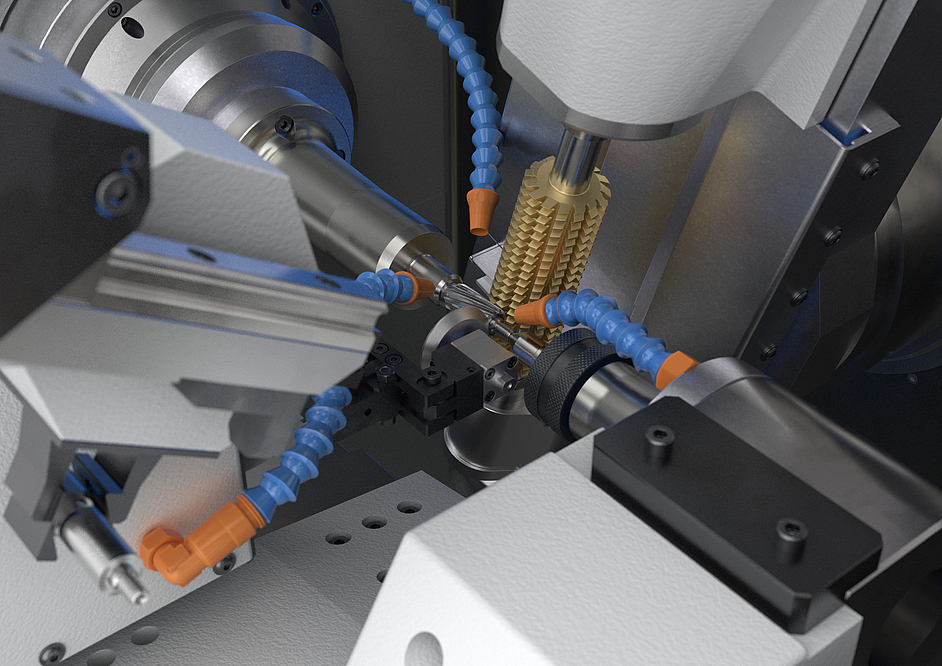

Horizontal Hobbing Machine with Integrated Chamfering Unit for Maximum Productivity

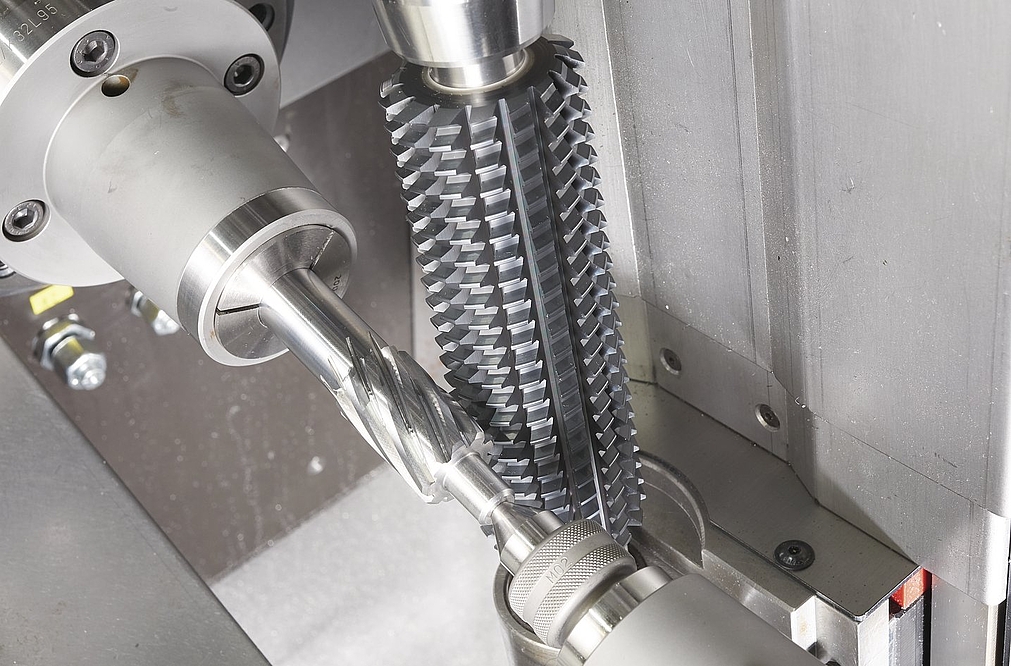

The special basic design with its “virtual Y-axis” unites an extraordinary hob head swivel range with latest drive technology.

In addition to spur and helical gears, efficient worm machining processes by means of the single index milling method with disc cutters is also possible.

The machine covers an incomparable wide workpiece range thanks to its huge axe distance between workpiece and cutter spindle. In case of hobbing applications, the workpiece range goes from small pinions, DP 48, diameter less ½ inch up to DP6 diameter 3 inches.

The use of direct driven, water-cooled workpiece and tool spindles guarantees long tool life.

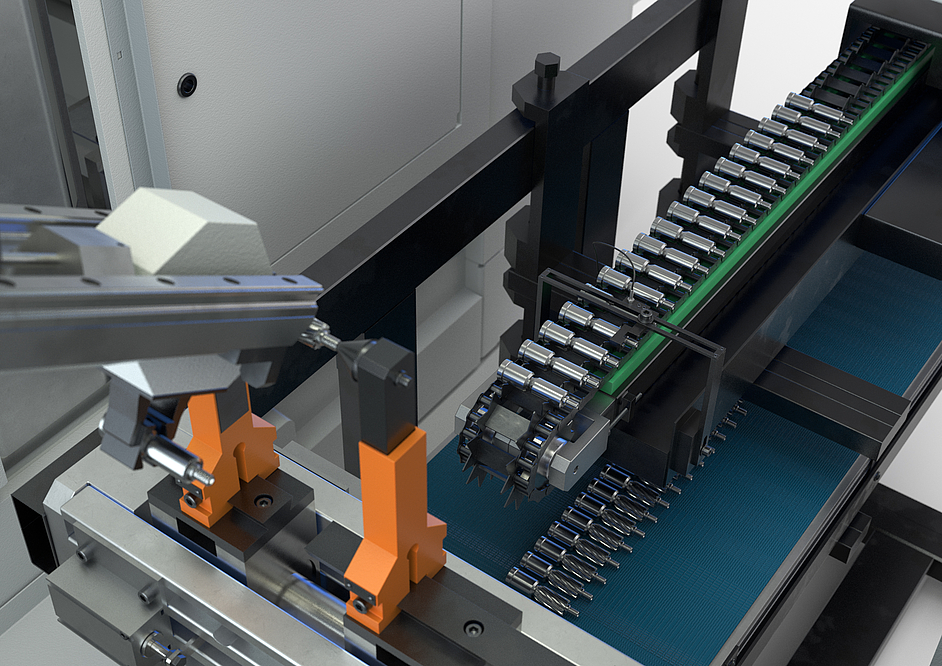

Short changeover times are possible by using optional quick clamping devices in small batch production as well as in serial production.

Depending on the workpiece range and the desired autonomy there is a wide selection of automation solutions spanning from manually loaded machines to stand-alone machines with automation up to fully integrated machines and machining systems.

Advantages HLC 150 H

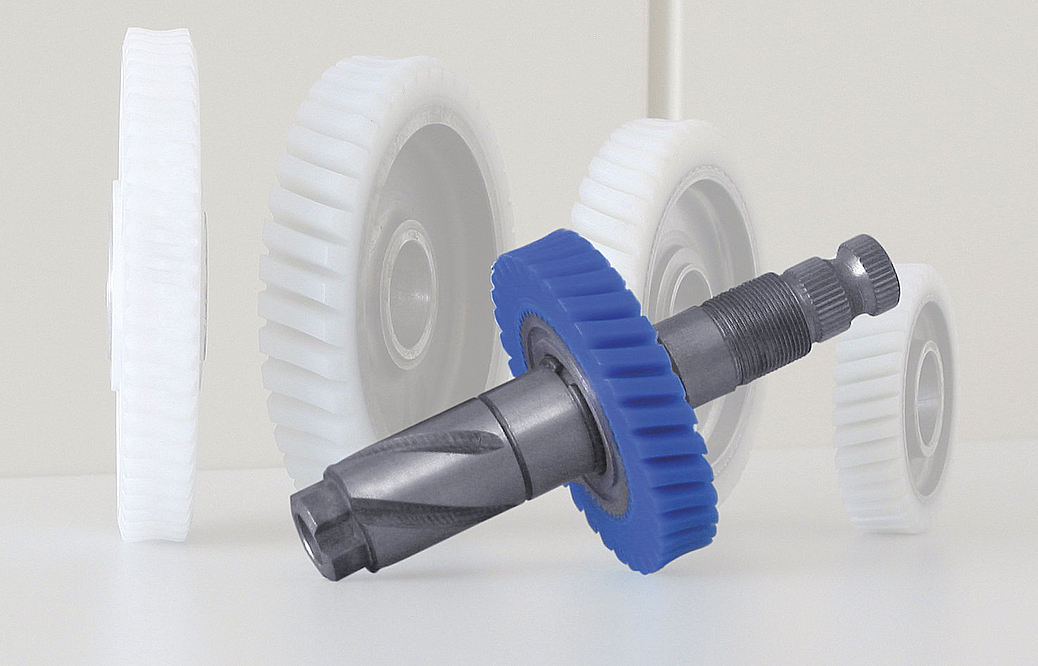

- Unique workpiece range from pinions, shafts and gears over wormgears and worms

- The “virtual Y-Axis” realizes a hob head swivel angle of 180° and 220mm shifting range at the same time

- Latest drive technology with outstanding performance factors for high performance machining

- Attractive cost-performance ratio

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any…

Industry 4.0

Technical Data

Module range

0.3 - 3.0 mm

Workpiece dia., max.

150 mm

6 in

Workpiece length, max.

500 mm

19.5 in

| Module range | mm | 0.3 - 3.0 |

| Workpiece dia., max. |

mm

in |

150

6 |

| Workpiece length, max. |

mm

in |

500

19.5 |

| Shift distance |

mm

in |

220

8.5 |