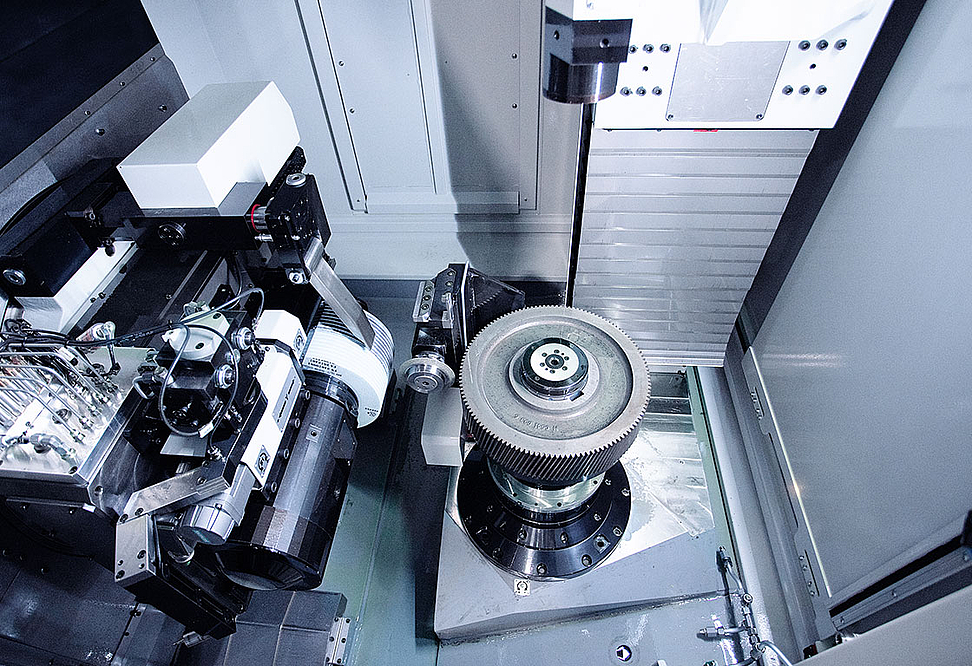

Gear Generating Grinding Machines

G 400

- Module area gear generating grinding: 0.5 / 8

- Profile grinding module area: 0.7 / 12

- Workpiece dia., max.: 400 mm | 15.5 in

Gear grinding machine G 400: Short cycle times for workpieces that are ground with generating and profile grinding.

G 400 - Highest precision for gearing requirements

Efficiency and precision in generating and profile grinding technology

The G 400 is a modern gear and profile grinding machine that has been specially developed for the machining of gears and shaft-type workpieces. It combines high precision, productivity and flexibility. With the ability to machine workpieces up to a diameter of 400 mm, this grinding machine offers innovative solutions for a wide range of industrial applications.

The G 400 generating and profile grinding machine is a universally applicable machine and is particularly suitable for contract gear cutting companies, gear manufacturing, the supplier industry, but also for applications in the truck, agricultural and construction machinery industries as well as in other branches of industry that require first-class surface finishes and dimensional accuracy.

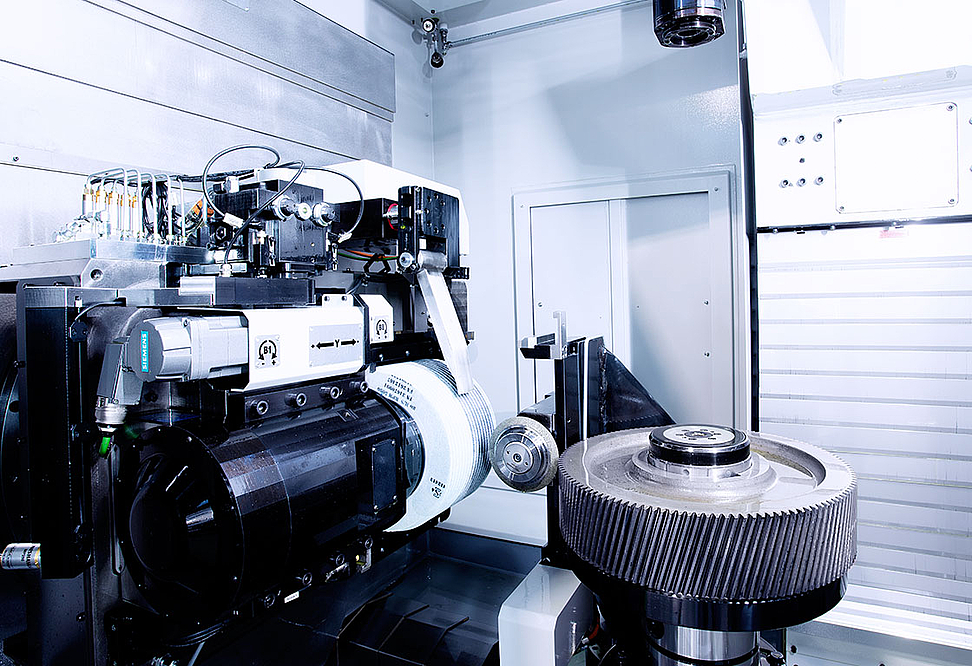

Highest precision in generating and profile grinding

The G 400 is characterized by good accessibility and set-up capability. The conversion from profile grinding to gear generating grinding can be carried out in a short time, which makes it interesting for companies with a large component range. In addition, a wide range of technologies can be used, from fine grinding and polishing grinding to a special technology for the production of noise-reduced tooth profiles. Visualization in the software also makes it easy for the machine operator to produce low-interlacing tooth profiles, which significantly reduces set-up times and underlines the machine's ease to operate.

Versatile applications with the G 400

The G 400 generating and profile grinding machine is suitable for both series production and prototype manufacture. Its modular design allows it to be adapted to individual requirements. From gear generating grinding to the machining of gears and shafts, the G 400 offers maximum flexibility for different grinding technologies.

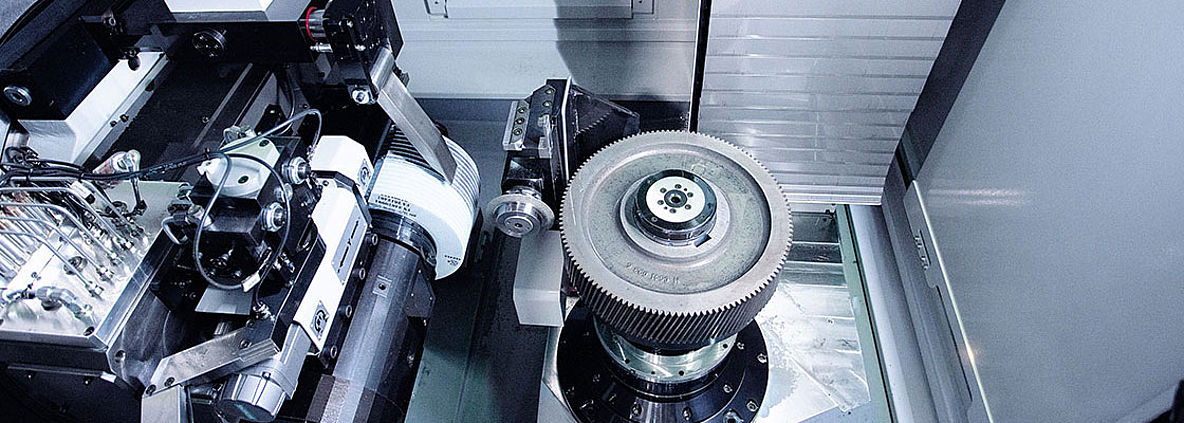

Advantages G 400

- Maximum workpiece diameter: up to 400 mm

- Module range: 0.5- 8mm for minimum machining times during gear generating grinding

- Module range: 0.7-12 mm for maximum flexibility in machining during profile grinding

- L-shaped machine door for loading with a crane

- HMI dialog program with clear inputs for the various machining requirements

- Thermal and mechanical stability: Guarantees perfect surface quality in generating and profile grinding operations

- Minimal set-up times: Fast tool change and intuitive operation enable maximum productivity.

- Generating and profile grinding on one machine including fine grinding and polishing as well as special technology for the production of low-noise tooth profiles

- Automatic loading with robot

- Twist-Control software with visualization for easy entry of the interlocks in the dialog program

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

During the machining of the tooth flanks of shafts and gears by means of generating grinding or gear grinding, it is important to achieve…

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…