Gear Generating Grinding Machines

G 250

- Module range: mm 0.5 - 7.0

- Workpiece dia., max.: 250 mm | 10 in

- Workpiece length, max.: 550 mm | 21.5 in

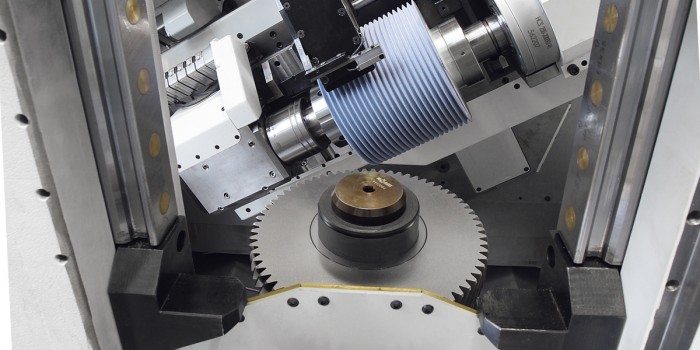

Gear generating and profile grinding machine G 250

The G 250 gear generating and profile grinding machine has been especially developed for very low cycle times and for top-quality and efficient mass production of gears.

G 250 Gear Generating and Profile Grinding Machine: Short Cycle Times and Premium quality for Mass Production

The EMAG SU G 250 gear generating and profile grinding machine is based on iron cast structure with high stiffness.

The machine is an innovative, compact and extremely flexible gear grinding and profile grinding machine.

The EMAG SU G 250 has been especially developed for very low cycle times and for top-quality and efficient mass production of gears with outside diameters up to 250 mm and shafts with lengths up to 550 mm. Moreover, the machine features dual work spindles that eliminate non-productive times almost completely.

Particular attention has been paid to the state-of-the-art solutions that allow a fast tool change, e.g. from profile to worm grinding, guaranteeing an unmatched process versatility.

This gear generating and profile grinding machine can use both gear generating grinding wheels and profile grinding wheels as well as grinding worms, both in ceramic and in electroplated CBN.

Simple design concepts in terms of tooling and dressing technology, fast automation and amazing user-friendliness are the strengths behind this unique machine.

Advantages G 250

- Customer-oriented solutions for each application

- Grinding with small worm grinding wheels is possible (diameter 110 to 90 mm with dressable wheels)

- Grinding of every kind of workpieces and complex geometries

- Loading and unloading of the workpiece in masked time

- Optional automatic workpiece loading and unloading

- Semi-automatic tool change

- Short chip to chip time

- High productive machine

- Minimal distance between the axes allows to use small profile wheels

- Twist control grinding, superfinishing and a special shift strategy for low noise gears

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

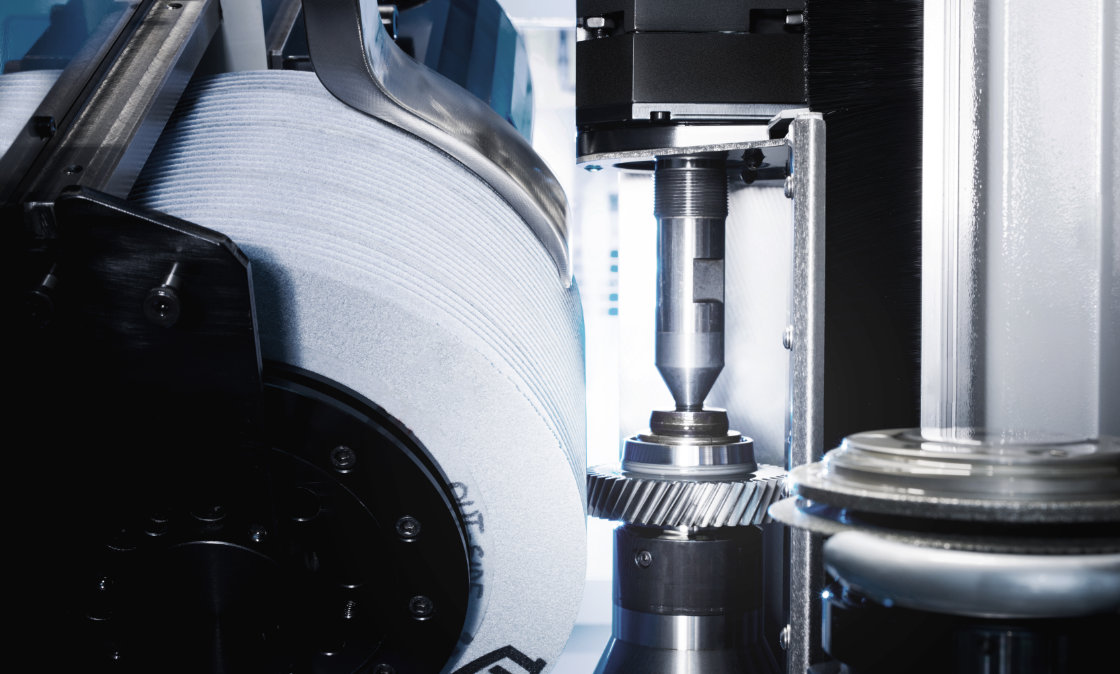

During the machining of the tooth flanks of shafts and gears by means of generating grinding or gear grinding, it is important to achieve…

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

Technical Data

Module range

0.5 - 7.0 mm

Workpiece dia., max.

250 mm

10 in

Workpiece length, max.

550 mm

21.5 in

| Module range | mm | 0.5 - 7.0 |

| Workpiece dia., max. |

mm

in |

250

10 |

| Workpiece length, max. |

mm

in |

550

21.5 |

| Face width, max. |

mm

in |

380

15 |

| Helix angle degree | ° | +45 / -45 |

| Grinding wheel dia. |

mm

in |

170

/ 250

6.5 / 10 |