ECM / PECM Machines

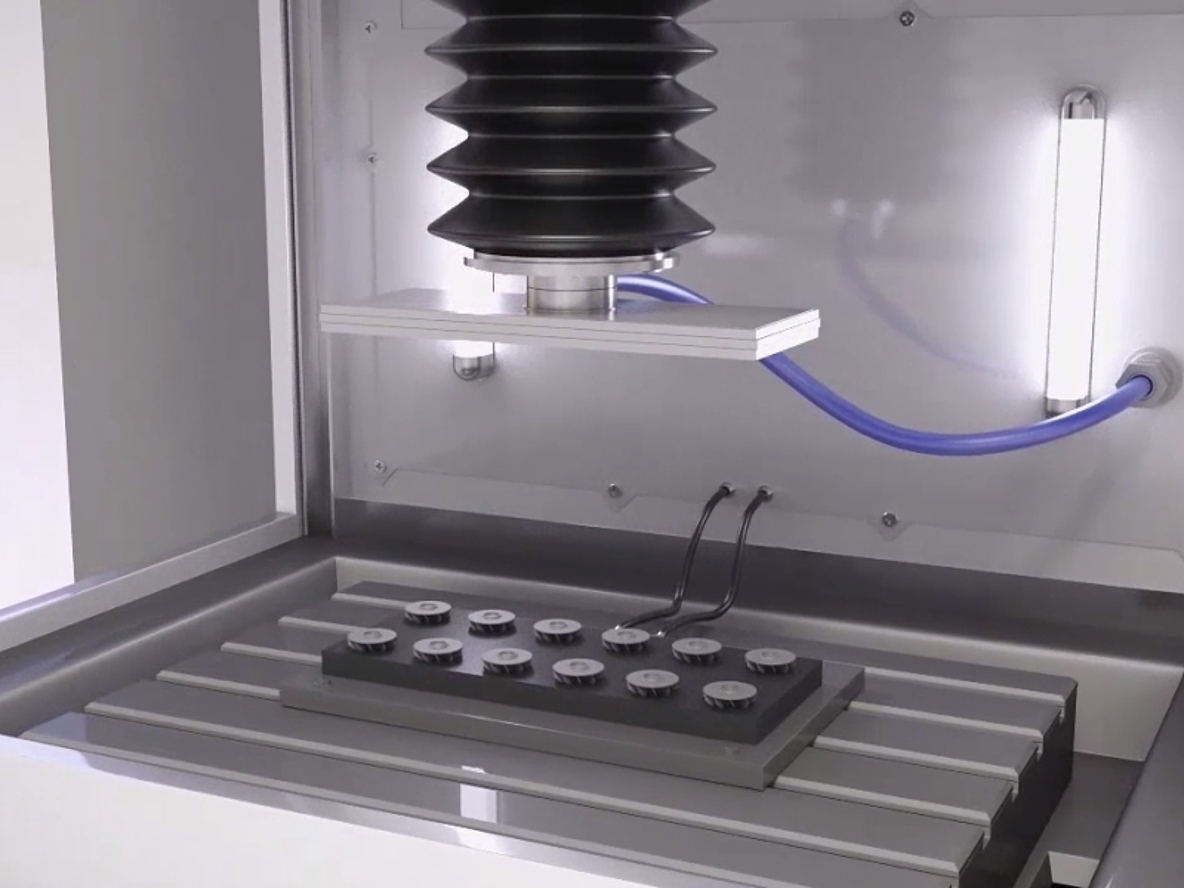

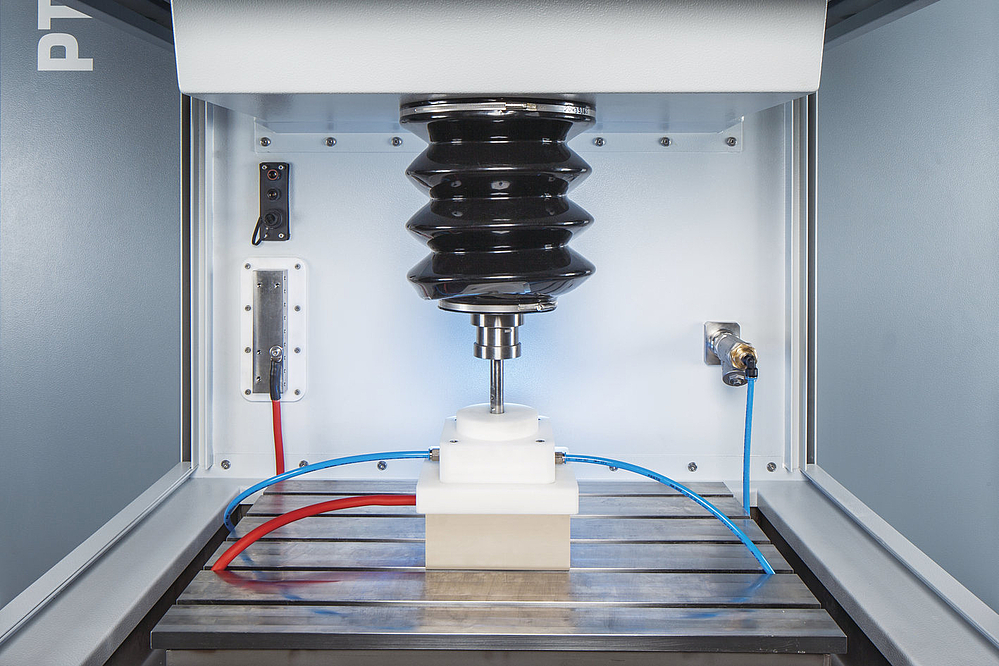

PTS 2500

- Machining area: mm 1.070 x 700 x 515

- Clamping surface: mm 800 x 550

- Generator capacity: A (DC) 2.500 – 5.000

PECM technology for manufacturing demanding structures and contours.

The PECM PTS 2500 helps complete difficult machining tasks by reducing process streams. The high reproducibility of this premium series of PECM machines is achieved thanks to an intelligent machine concept and our patented PECM technology.

PECM (Precise Electro-Chemical Machining) on EMAG's PECM systems.

The EMAG PTS 2500 enables the highly precise integration of demanding geometries. The EMAG ECM and PECM technology applied here is an excellent option, even if many developers and design engineers are still unfamiliar with it. The process always stands out where complex components have to be produced from demanding materials. High rigidity alloys and similar materials are processed nearly no tool wear. This produces surfaces with maximum quality – without burr formation or changes to the material's microstructure.

Advantages PTS 2500

- MINERALIT® polymer concrete machine base

- Clamping plate with M12 T grooving

- SIEMENS SINUMERI K 840D sl machine control unit

- Hydraulic zero point clamping system

- Oscillator with zero backlash

- Optional: XY table

- Optional: Rotary table as C-axis

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Electro-Chemical Machining (ECM) is the generic term for a variety of electro-chemical processes. ECM is used to machine workpieces through the anodic…

Many components do not only have to be highly precise on the outside, but the primary focus is on generating optimal surfaces on the internal…

The use of electro-chemical metal removal processes guarantees surfaces of the highest quality - even on filigreed components. To achieve even greater…

Technical Data

Machining area

1.070 x 700 x 515 mm

Clamping surface

800 x 550 mm

Generator capacity

2.500 – 5.000 A (DC)

| Machining area | mm | 1.070 x 700 x 515 |

| Clamping surface | mm | 800 x 550 |