ECM / PECM Machines

PI

- Generator capacity: A (DC) 400 – 2.500

- Generator capacity: A (pulse) 400 – 8.000

Premium Integrated (PI): The optimal entry-level machine for the (P)ECM process

With the PI modular machine platform, EMAG’s successful concept, i.e. same basic structure combined with customized technology, now also makes inroads at EMAG ECM. This offers you maximum flexibility for your machining projects in the area of electrochemical machining (ECM/PECM).

The right module for each application in electrochemical machining.

Electrochemical machining (ECM or PECM) can be used to machine a great number of different workpieces. Which technology comes to be used depends on the requirements of the workpiece. ECM can be implemented for deburring, drilling, inside profiling or even for gear cutting. If you want to achieve a high level of reproduction accuracy, then PECM is the right choice.

EMAG ECM already offers highly specialized machine solutions for both technologies, which are implemented for a wide variety of industries throughout the world. Above all, ECM and PECM are implemented wherever demanding materials (e.g. very hard) are to be machined or if material removal technologies reach their limits or simply are too expensive, e.g. if a burr and chip-free component can only be achieved through elaborate finishing.

Despite the many advantages that the technology offers, it remains unknown to many users. EMAG ECM now wants to change this with its new PI. To achieve this, the PI ECM machine draws on the successful principle of the CI deburring machine—a machine design that always remains the same and a technology that perfectly matches the application. This allows for fast delivery, low costs and above all simpler handling.

To begin with, there is the compact machine design. The entire machine technology, incl. modular electrolyte management and electrical engineering, fits onto a forklift-compatible basic framework. Yet, the actual revolution is the modular design of the machining area. Users can choose from four modules: The PECM module with oscillator, the ECM countersink module, the ECM rifling module and the ECM deburring module, all suitable for simultaneous machining of several identical workpieces.

Mineralit for highest precision

Each of the modules, except for the deburring module, is built onto a machine base made of MINERALIT® polymer concrete, a further innovation that has been adopted from EMAG’s modular machines. MINERALIT® has optimal vibration-damping properties and contributes to the modules’ high precision. The linear guides with absolute measuring systems, which ensure high rigidity and precision during machining operations, are fastened onto the machine base.

Advantages PI

- Scalable generator technology up to 2,500 A

- DC, pulse, and PECM technology

- Flexibly configurable pulse technology

- Individual cathodes can be selected/deselected

- Single cathode monitoring

- Process control using by time, distance, or ldt

- Small footprint

- Modular design

- Touch panel and S7-1500 controller from Siemens

- Conductivity monitoring

- Temperature control

- pH value control with metering

- Transportable by a forklift truck

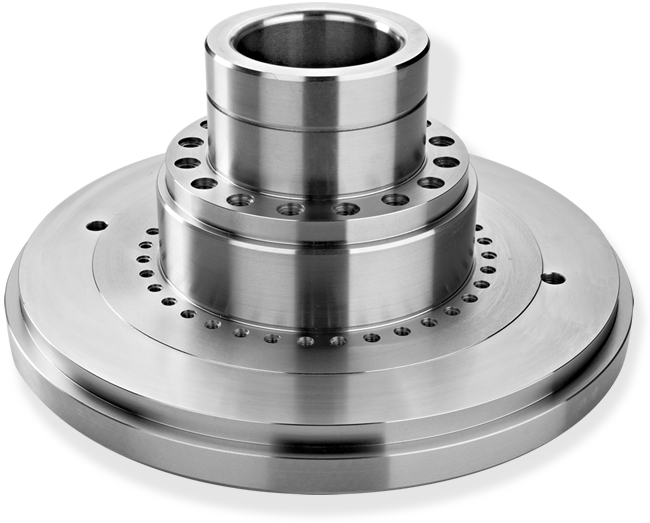

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Chip-producing drilling is a fast and effective process for many applications.

However, what to do when the pressure on the tool that is supposed to…

ECM is the ideal technology for machining rifle barrels. The use of a special rifling module in the modular PI machine produces high-precision…

The use of electro-chemical metal removal processes guarantees surfaces of the highest quality - even on filigreed components. To achieve even greater…

Technical Data

Generator capacity

400 – 2.500 A (DC)

Generator capacity

400 – 8.000 A (pulse)

| Generator capacity | A (DC) | 400 – 2.500 |