Automation of Machine Tools with CRC robot cells – reliable, fast and efficient

The automation of machine tools using robots opens numerous benefits for production, making the entire process faster and more cost-efficient and reliable. EMAG’s pick-up technology is particularly suitable for this, since the machines’ internal automation system means they can be loaded and unloaded very effectively with robot solutions and can be interlinked.

CRC Robot Automation Cells adapted to meet Customer Requirements

You can see how different the robot solutions from EMAG are by looking at the details. The parts can be fed, for example, pre-aligned in baskets or in drawers, unordered as bulk material or with feeding and out feeding conveyors.

CRC Automation Cell with Basket Stacking

In automation cells with basket stacking, the loading and unloading of the system is done using baskets from which the robot grabs the pre-aligned workpieces or deposits them. The empty baskets are placed onto the stack by the robot.

CRC Automation Cell with Drawer System

With the drawer system, the workpieces are provided to the robot on different levels. While the drawers are being filled, the robot in the cell supplies workpieces to the machine.

Benefits of the EMAG Robot Cells:

- Automation system tailored perfectly to the EMAG machining units

- Compact automation system from a single source from EMAG; all interfaces are clear

- Economic production due to optimum machine utilization

- Low level of strain on the personnel

- High storage density in small installation area

- Relatively low investment costs

- Simple retrofitting option for existing EMAG machines

Robot Automation Examples

Two VL 3 DUO with Robot Automation:

The robot enables several options in combination with the two separate machining areas of the machine. For example, two components are initially machined simultaneously from one side in the first machine. The robot then picks them up, flips them over and feeds them to the machine for simultaneous machining of the second side. The result is high output volumes within short periods of time.

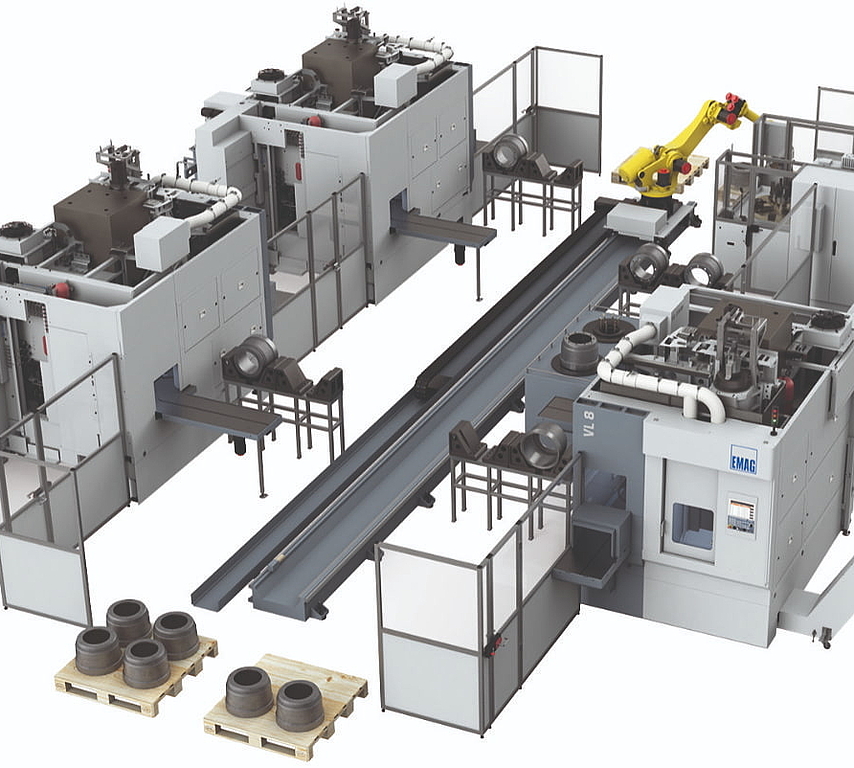

VL 8 with Robot Automation

Complete solution for the truck drum brake: The robot loads four machines of type VL 8, with a very high component weight. While doing so, it traverses very quickly on a rail. The basic principle is therefore equivalent to the "TrackMotion approach."