Fingerprint

Fingerprint allows you to increase machine availability and productivity while minimizing workpiece costs.

Fingerprint

Fingerprint allows you to increase machine availability and productivity while minimizing workpiece costs.

Assess Machine Condition – At Any Time.

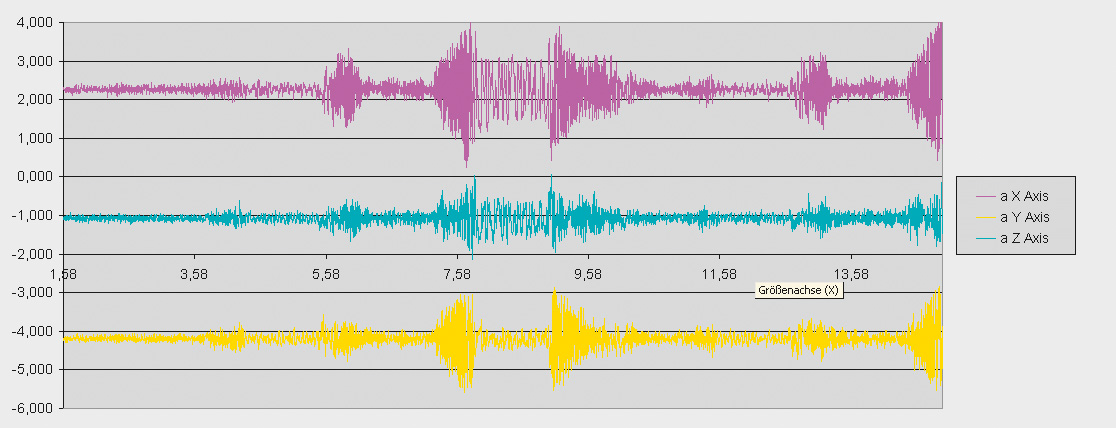

Historically, the diagnosis of the condition of a machine tool axes has been done either based on gut feel or a long, drawn out measuring process. Accurate data for preventive maintenance has either been unavailable, or required a lot of work to be obtained. This has made it very difficult to plan for necessary maintenance, and makes wear-based component replacement nearly impossible.

With Fingerprint however, the EMAG service department has the ability to easily diagnose and evaluate the condition of your machines mechanical components – with no lengthy disassembling and reassembling. The data provided by the Fingerprint gives you a current status report for your machine.

Fingerprint is available in two forms:

- By request (mobile Fingerprint)

- Permanently (hard-wired Fingerprint sensor)

Advantages Fingerprint

- Increased machine availability due to status-oriented maintenance

- Longer machine lifetime

- Planned machine downtime for maintenance work, prevention of unplanned machine failures

- Verifiable results with clear parameters

- Precise and comparable results

- Status history available

- A precise analysis avoids the replacement of the “wrong parts”

Technical Hotline

Our technical hotline records all inquiries and gives you technical assistance

+49 7162 17-4300

service.salach@emag.com