Modular VL

VL 8

- Workpiece dia., max.: 400 mm | 15.5 in

- Workpiece length, max.: 300 mm | 12 in

- Chuck dia., max.: 500 mm | 19.5 in

VL 8 - CNC Turning at the Highest Level for Chucked Parts up to 400 mm in Diameter

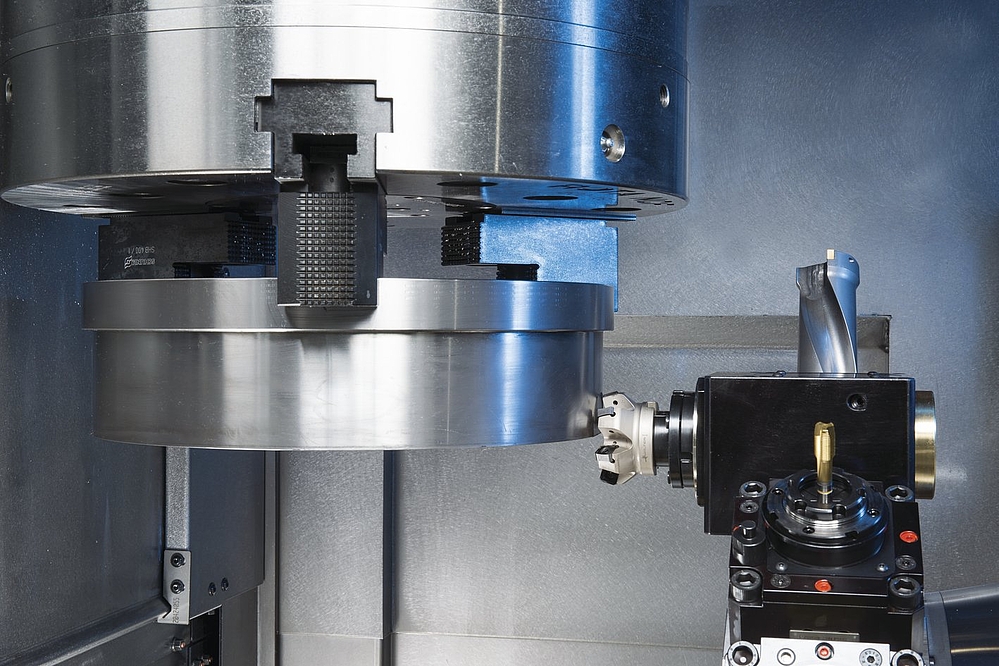

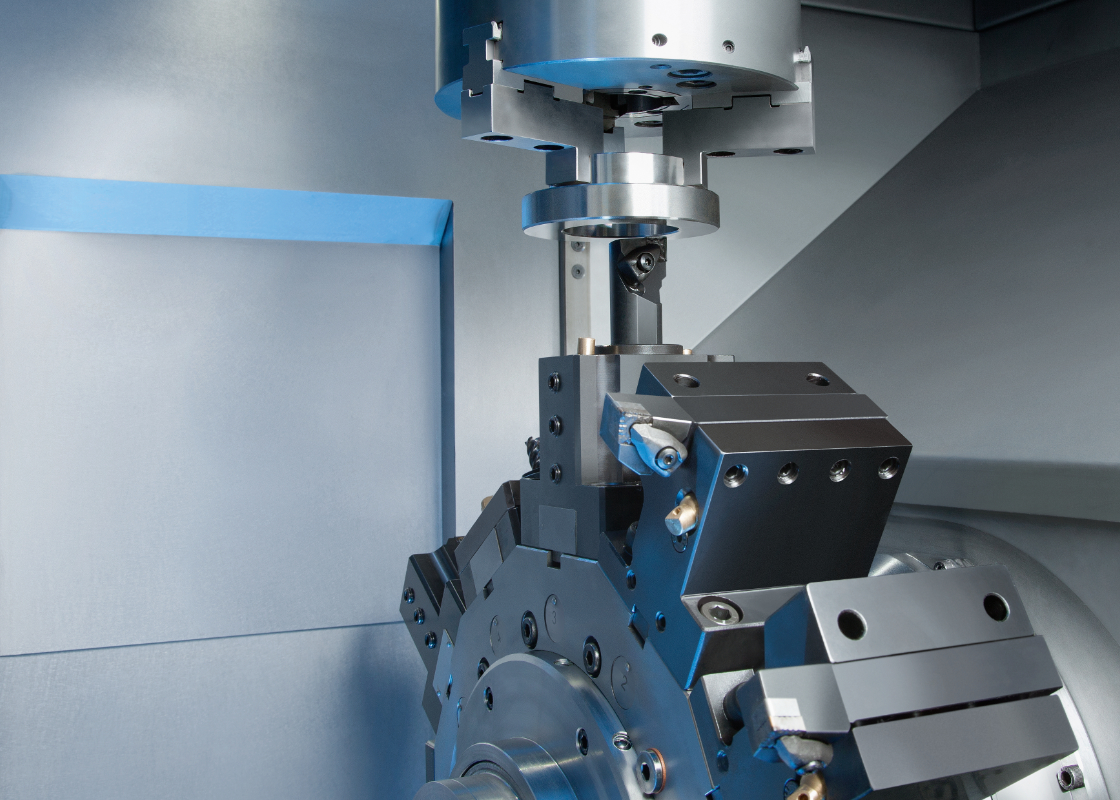

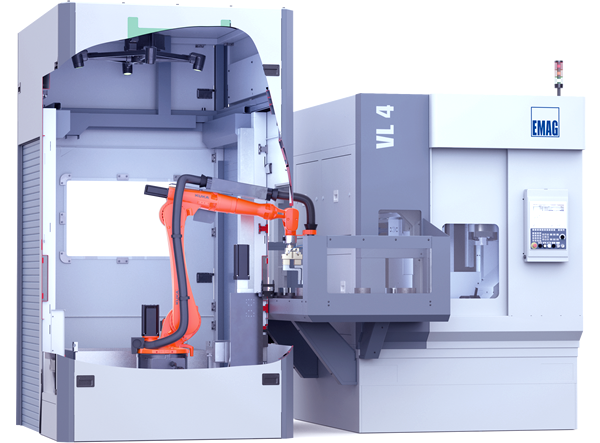

With the VL 8 vertical pick-up turning machine EMAG makes the advantages of its VL series available for large parts as well. The automation system integrated into the turning machines guarantees rapid processing, while the stable basic structure of the machine ensures top quality in turning and milling. The vertical design likewise contributes to the high machining quality, as it virtually eliminates all effects of chips generated during machining.

Vertical Lathes with Integrated Automation for Large Workpieces

The cornerstone of the VL 8 turning machine is a machine base of MINERALIT® polymer concrete that guarantees a vibration resistant process, providing for excellent tool life and outstanding machining quality. The pick-up spindle collects the workpieces from a lateral conveyor belt, transporting them the short distance to the machining area to ensure short chip-to-chip times. The machining process is highly flexible, allowing for the use of a large variety of tools. Machines are easily interlinked and the integration of a Y-axis in the turret allows for the “off-center” machining of more complex geometries.

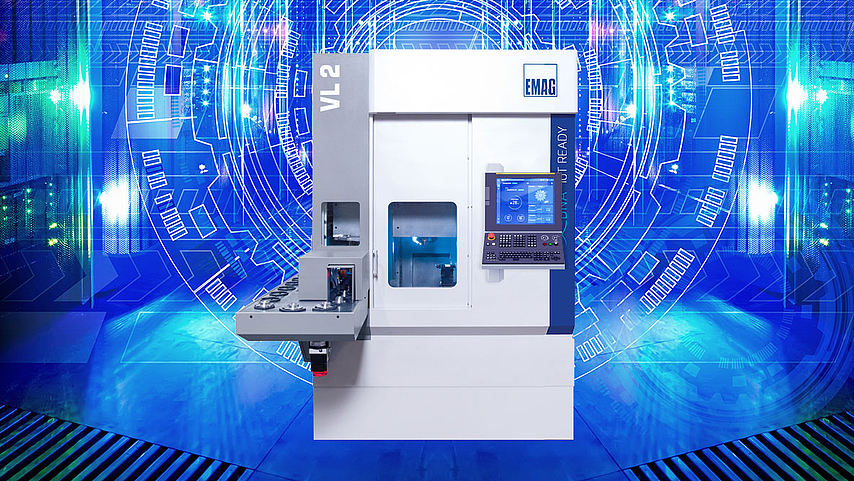

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VL series

Using data analysis, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VL Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

Advantages VL 8

- Small footprint (chaku-chaku or close linear arrangement) for reduced floor space costs and more possibilities for machine layout

- Simple interlinking via central feeding and discharge belts and pick-and-place or turnover units = flexible in regards to future developments, lower automation costs and shorter tooling times

- Integrated automation at no additional cost

- Short transport distances = optimization of idle times

- Common parts strategy, standard spare parts warehousing for lower maintenance costs

- Ease of operation (extremely accessible machining area) and quicker machine set-up

- High energy efficiency reduces energy costs

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Digitalization

Digitalization @ EMAG - The Future is Connected

Industry 4.0

Technical Data

Workpiece dia., max.

400 mm

15.5 in

Workpiece length, max.

300 mm

12 in

Chuck dia., max.

500 mm

19.5 in

| Workpiece dia., max. |

mm

in |

400

15.5 |

| Workpiece length, max. |

mm

in |

300

12 |

| Chuck dia., max. |

mm

in |

500

19.5 |

| Swing diameter |

mm

in |

520

20.5 |

| X-axis travel |

mm

in |

1,110

43.5 |