Modular Shaft Machining VT

VT 4 / VT 200

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 630 mm | 25 in

- Chuck dia., max.: 250 mm | 10 in

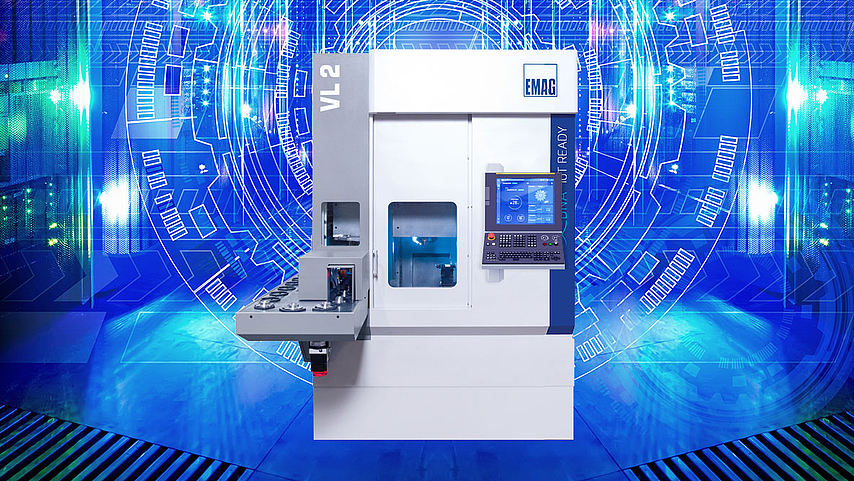

High precision vertical turning centers for efficient shaft machining: VT 4 / VT 200

Vertical turning centers with integrated automation, simultaneous 4-axis machining and IoT-ready technology.

Precise and reliable shaft production

Advanced Machining Capabilities

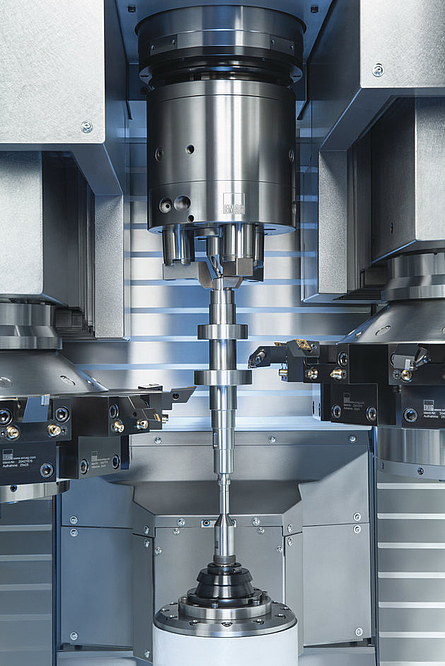

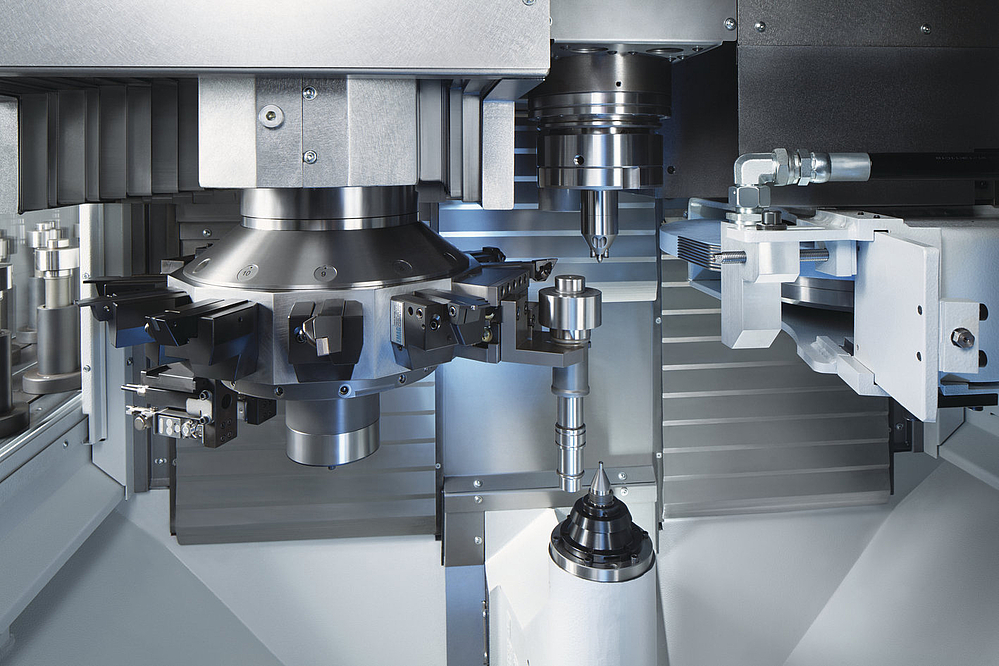

The VT 4 and the VT 200 are identical machines except that the VT 200 is equipped with a Siemens control unit. Both are designed to machine shaft parts up to 24.8” (630 mm) in length and up to 7.87” (200 mm) in diameter. Two tool turrets with eleven tool posts each are available for machining (one tool post on each turret is occupied by the workpiece gripper). This enables simultaneous four-axis machining of workpieces from two sides.

Workpiece grippers transfer the raw parts into the turning center and pick them up again after machining, reducing chip-to-chip times as well as related component costs.

Depending on the workpiece, this changeover time lasts only about six seconds. Simultaneously turning from two sides using 4-axis machining makes the actual turning process very fast, too. The vertical arrangement of the component also ensures long-lasting process reliability, since gravity assists chip flow, helping avoid chip build-up in the machine compartment.

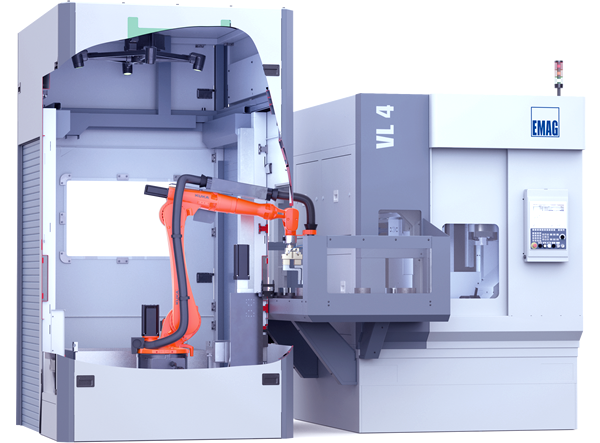

Integrated Automation System

In our VT turning centers, automatic loading and unloading is an integral part of the machine – a full-featured automation system is included. The workpiece grippers in the two turrets move the raw parts from the workpiece conveyor into their vertical position in the turning center. The conveyor is implemented in the form of an incremental chain conveyor with workpiece carriers.

Various workpiece lengths and diameters are defined in the NC part program.

Applications in Shaft Production

The VT 4 and VT 200 are ideal for manufacturing:

- transmission shafts

- rotor shafts

- pump shafts

- and engine shafts

EDNA IoT-Ready Technology

The future is connected at EMAG. Get started with data-optimized production with a VT 4 or VT 200 turning center. Both models come IoT-ready. Using data from our EDNA analytic software, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity improvements of more than 10% are typical with our solution. Since all the machines of the VT Series now come standard in an IoT-ready state, data analysis on the machines can be started virtually immediately.

Advantages VT 4 / VT 200

- High precision and efficiency: short cycle times and simultaneous four-axis machining for enhanced productivity.

- Integrated automation: automatic loading and unloading with workpiece grippers for reduced idle times.

- Robust process reliability: vertical arrangement ensuring free downward chip flow to prevent build-up.

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Digitalization

Digitalization @ EMAG - The Future is Connected

Technical Data

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

630 mm

25 in

Chuck dia., max.

250 mm

10 in

| Workpiece dia., max. |

mm

in |

200

8 |

| Workpiece length, max. |

mm

in |

630

25 |

| Chuck dia., max. |

mm

in |

250

10 |

| Swing diameter |

mm

in |

270

10.5 |

| Gripper diameter, max. |

mm

in |

133

5 |