창성식 기어 연삭기

G 250 HS

- 기어 창성 모듈: 0.5 / 5

- 프로파일 연삭: 0.5 / 7

- 최대 공작물 직경: mm 250

G 250 HS gear grinding machine - highest productivity level for workpieces with interfering contours

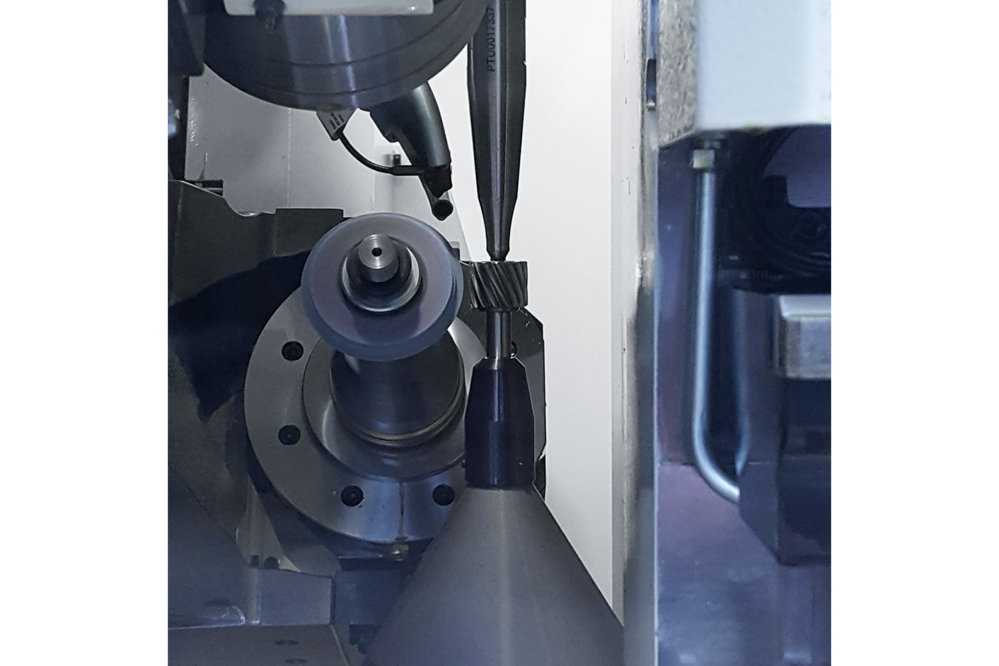

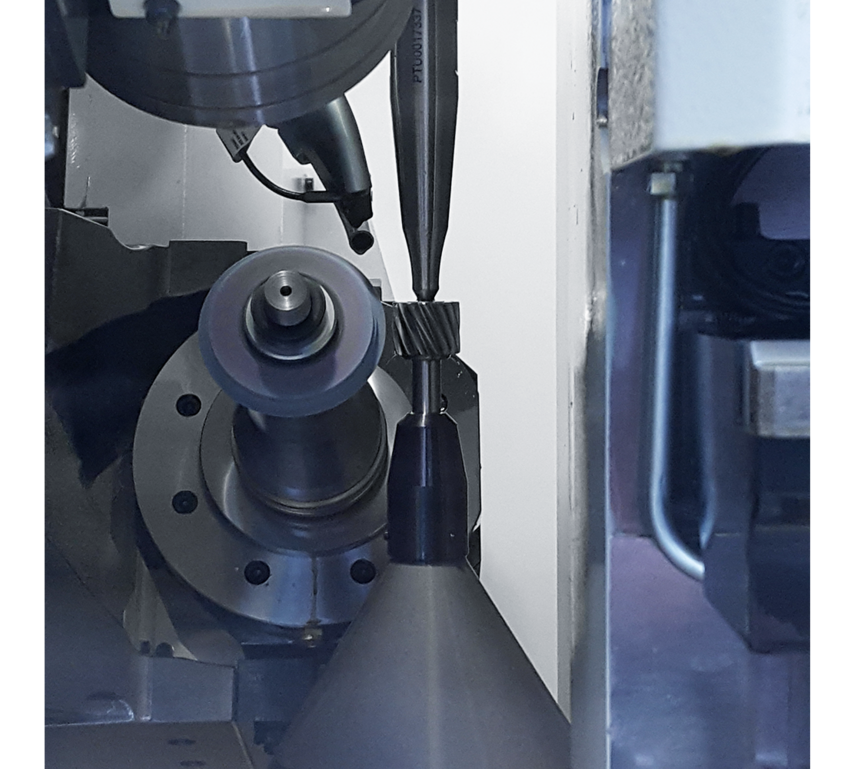

The G 250 HS from EMAG SU is a gear profile grinding machine that has been specially developed for the production of gears and shafts with interfering contours. Thanks to the high-speed grinding head and the high-productivity use of smaller grinding wheels, workpieces with complex geometries and grinding positions that are difficult to access due to interfering contours can be machined with precision and efficiency. With its compact design and high degree of flexibility, the G 250 HS is the ideal solution for highly complex production tasks, such as those frequently encountered in the geared motor sector.

Innovative technology for precision gear production

With its highly rigid cast iron bed construction, the G 250 HS guarantees stability and precision. Conversion from generating grinding to profile grinding is possible in just a few minutes, as both processes take place on the main spindle, thus increasing flexibility in production. Generating grinding is carried out with ceramic dressable grinding wheels, while electroplated CBN, dressable CBN or dressable ceramic wheels are used for profile grinding. Due to the high motor speeds on the grinding head, even very small profile grinding wheels can be used economically.

The machine machines gears and shafts with small ceramic or CBN grinding wheels and offers efficient production solutions for demanding requirements thanks to its excellent accessibility and short set-up times. The G 250 HS is suitable for both small and large series production and is very easy to integrate into manufacturing systems.

이점 G 250 HS

- High-speed grinding head: The powerful grinding head enables generating and profile grinding of workpieces with interfering contours.

- Machining of gears and shafts: Machines gears up to an O/D (Outer Diameter) of 250 mm and shafts up to a length of 550 mm.

- Minimum center distance: Particularly suitable for grinding small workpieces with small grinding wheels.

- High efficiency: Two work spindles virtually eliminate non-productive time, resulting in shorter cycle times.

- Versatile grinding processes: Quick change between profile and gear generating grinding on the main spindle for maximum process flexibility.

- Optimized tool and dressing technology: This machine is characterized by simple and fast automation and high user-friendliness.

기술

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

During the machining of the tooth flanks of shafts and gears by means of generating grinding or gear grinding, it is important to achieve…

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…