Condition analysis of your equipment with 3D sensors and data backup

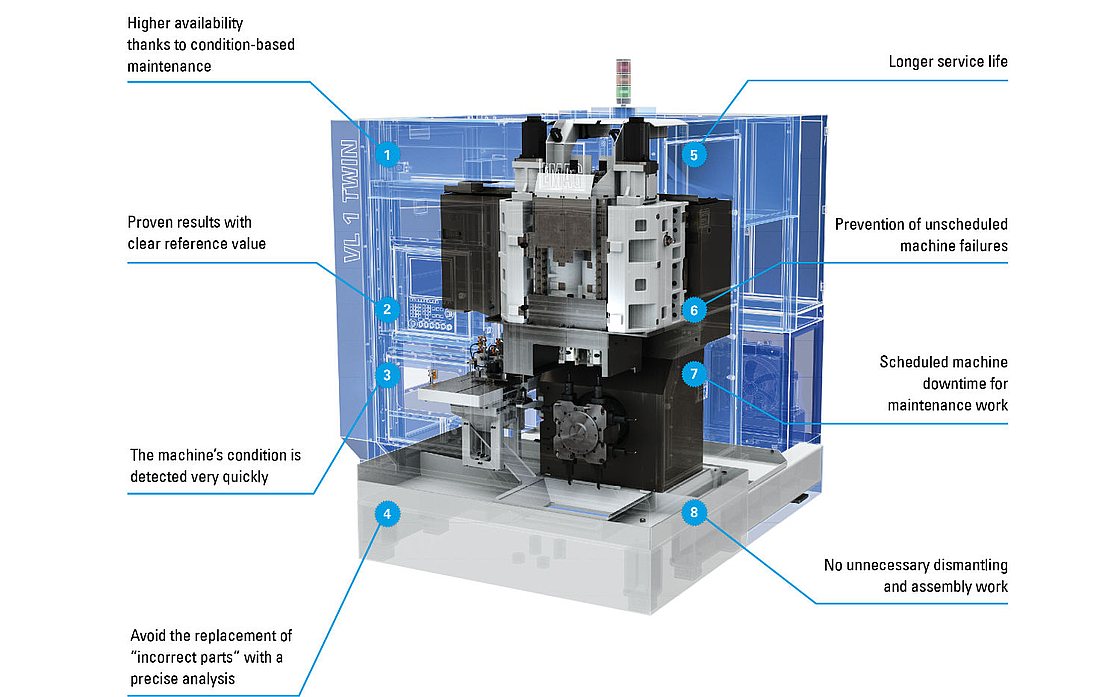

An accurate diagnosis on the condition of the machine tool axes is usually made based on gut feel or the result of time consuming, difficult to obtain measurements. Often times, exact data for preventive maintenance is not available, or can only be collected by incurring high costs. This uncertainty makes it difficult to plan maintenance, and nearly impossible to change components within the machine based on their current condition.

Using 3D sensors, EMAG Service produces a diagnosis that provides information on the condition of a variety of mechanical components. The benefit here is that no unnecessary dismantling or assembly work is required to perform a machine evaluation. Using the data provided from this diagnosis, you can obtain a completely up to date machine status report.

Data Backup

Having a current data backup ensures that all data relevant to the machine is available to minimize down times in the event of a failure of electrical components such as a hard drive, NCU, PCU, discharged buffer battery, etc.

The data backup contains the following features:

- Archiving in the EMAG data archive

- Data backup for customer on an external data medium

Services on site:

- Completion of the condition analysis using 3D sensors

- Completion of a data backup

Not included:

- Travel expenses

Technical Hotline

Our technical hotline records all inquiries and gives you technical assistance

+49 7162 17-4300

service.salach@emag.com