ECM Rifling Ensures Perfect Internal Geometries on rifled barrels

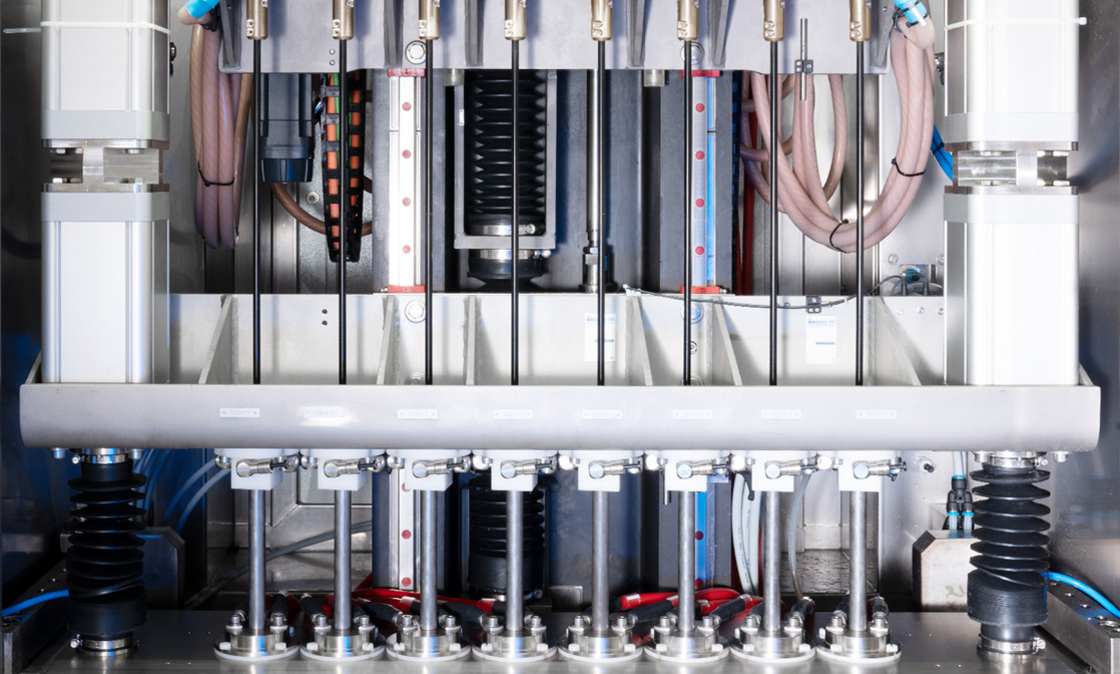

ECM is the ideal technology for machining rifle barrels. The use of a special rifling module in the modular PI machine produces high-precision internal geometries on short and long barrels.

ECM Rifling with special Rifling module

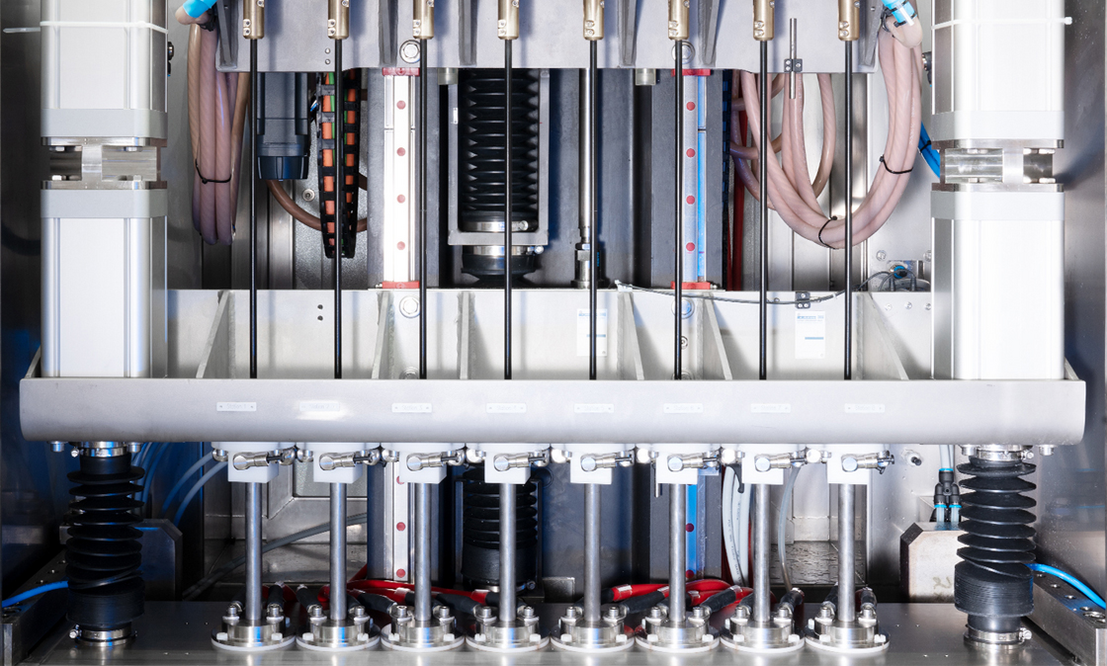

EMAG ECM uses a clever technology concept that has been specially developed for rifling. The quality-determining technology is located in the rifling module, which is inserted into the PI ECM machine depending on the requirements. According to the production volume, a double or eight-fold module is used so that two or eight barrels can be machined simultaneously.

With ECM rifling, the tool cathode generates the desired internal geometry of the barrel with high precision. A variety of different geometries are possible, for example “polygonal”, “progressive” or “standard rifling”. It is faster than the frequently used hammering process and has lower investment costs.

The process is completely safe throughout, with very easy cathode exchange and fast component loading. Drawing on our 20 years of experience in the development of ECM processes, the solution is suitable for short and long barrels, and almost any inner geometry is possible.

이점 ECM Rifling

- Low investment costs

- Up to 8-fold parallel machining for short cycle times

- Fast tool changes

- Almost any internal geometry possible

- No mechanical or thermal stress on the component

- No vibrations in the manufacturing

- Low-noise process

- Minimal footprint

기계 고객의 요구에 부응

(1) 대 기계 발견