04/21/2022 - Oliver Hagenlocher - Press

EMAG at the Grinding Hub 2022

Grinding solutions for components from electromobility, data-optimized production and much more

이미지

Flexible and at the same time highly productive solutions for grinding for electromobility and the like – this is what the EMAG Group will be demonstrating at the GrindingHub from May 17 to 20 in Stuttgart. The company has put together an interesting programme for the new trade fair for grinding technology. In addition to exhibits such as the universal cylindrical grinding machines from EMAG Weiss and the VLC 350 GT combination machining machine, EMAG will give an insight into developments in the field of Industry 4.0 and IoT, in which a lot has happened in recent years – including in grinding technology.

Whether electric drive, hybrid motor or conventional drive – production planners face the great challenge of developing a wide range of manufacturing solutions for the future. On the one hand, they need new production solutions for a wide variety of components, on the other hand, costs must be reduced and production processes optimized.

EMAG is also aware of this challenge and therefore began investing in digital solutions in addition to machining technologies a few years ago. EMAG's customers are now benefiting from this investment in networked production, and with the combination of highly productive production technology and data analysis, they have completely new ways of production planning and thus possibilities for cost optimization at their disposal.

EDNA IoT Solutions

The future belongs to data-optimized production, EMAG is convinced of this. Optimizing cycle times and unit costs is important, but EMAG goes one step further and focuses on overall plant efficiency (OEE) and its optimization based on production data. Through data analysis, unnecessary downtimes, e.B. due to component wear or, in the worst case, due to the failure of a machine, can be reduced or even completely avoided. Productivity increases of over 10 percent are the rule here.

In order to make it as easy as possible for EMAG customers to enter the world of data-optimized production, machines can now be delivered IoT-Ready. This makes it possible to integrate the machines directly and without major effort into existing IoT networks. An EDNA IoT Core (an IPC) is then installed in the control cabinet of the machines, which is already fully installed and networked with the machine control. In addition, the machines can be equipped with the EDNA Neuron 3DG sensors (acceleration sensors), which enables regular automatic monitoring of machine health. With the right software offer from EMAG, data-optimized production can be started directly.

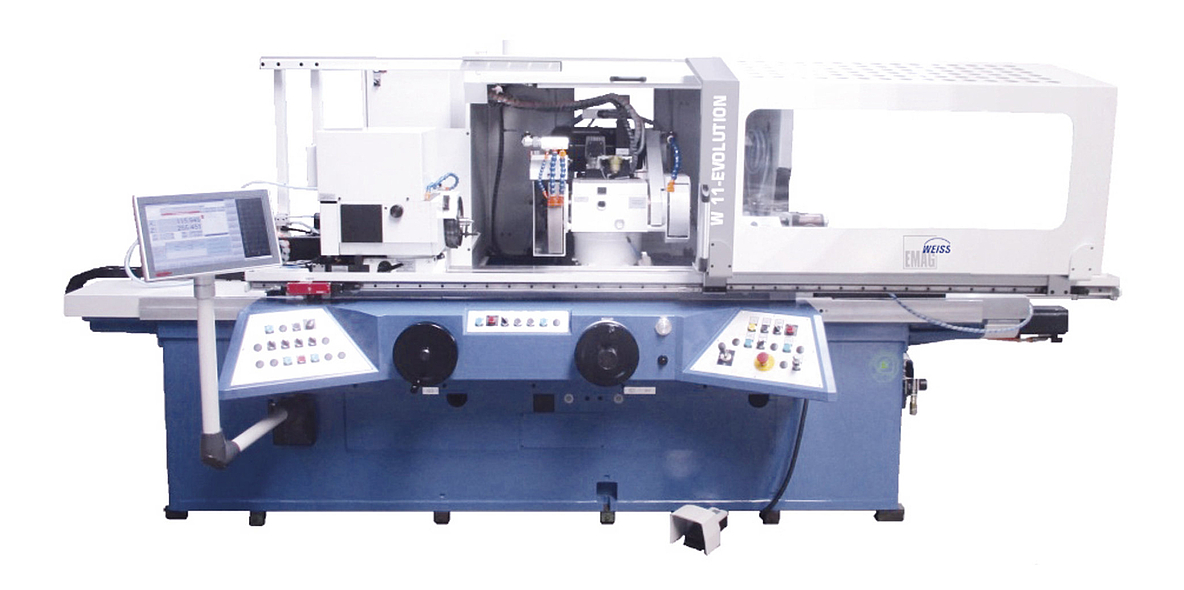

Grinding solutions from EMAG Weiss

CNC technology Weiss has made a name for itself in recent years as a successful developer of cylindrical grinding machines. Founded in 1993, the company has acquired its know-how through the maintenance and modernization of Karsten's cylindrical grinding machines. Since 2002, CNC-Technik Weiss has had its own range of cylindrical grinding machines, ranging from classic conventional cylindrical grinding machines to high-tech CNC cylindrical grinding machines. Weiss is now showing two of these machines at GrindingHub: a W 11 CNC and a W 11 EVO. The W 11 CNC is a grinding machine equipped with a modern, fast, grinding-oriented control. It can be used to automate many operations. If, for example.B the diamond and the workpiece are set, it can be done fully automatically. Radii, slopes, profiles and much more – the dressing amount is compensated fully automatically. The W 11 EVO is a further development of the well-known K11 series from Karstens. It is a new, contemporary version of the conventional grinding machine with many extras that make production life easier: hydraulic-free, axle drives with servo motor and ball screw, modern HMI with touchscreen, automatic parallel dressing and free-driving and much more.

Both machines offer the highest precision in external round machining with a grinding length of up to 2,000 mm and a maximum grinding diameter of 360 mm.

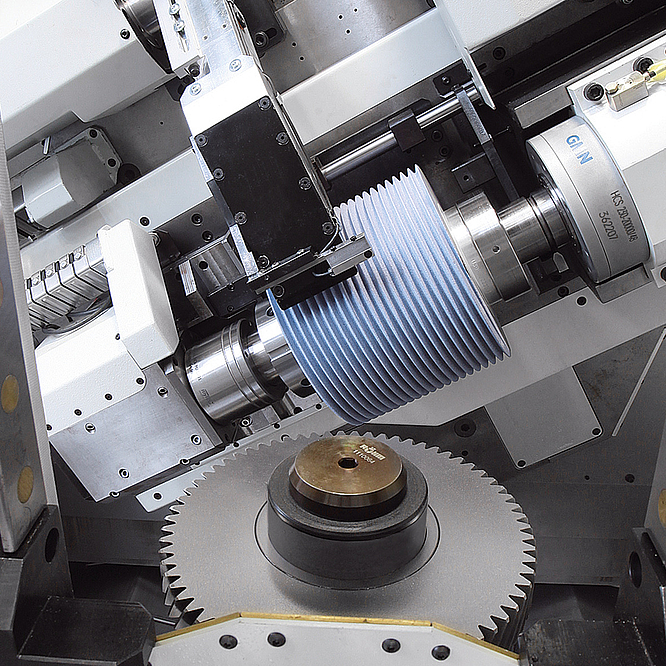

Combination machining with the VLC 350 GT

EMAG will also be presenting a VLC 350 GT for the first time at GrindingHub. The abbreviation "GT" stands for the words "Grinding" and "Turning". They indicate the great strength of this machine: The combination of grinding and turning (plus other processes) with the proven EMAG pick-up automation enables countless manufacturing solutions. The complete machining of e.B. transmission components can be mapped with it. The machine is designed for components up to 350 millimeters in diameter and offers the option of integrating a grinding spindle with NC swivel axis. On it, for example, there is a cylindrical abrasive with which internal holes can be ground. It is fundamentally important that the combination of (hard) turning and grinding ensures fast processes and high machining quality: After turning, only a residual thickness of a few mikrons remains. The grinding process with corundum or CBN grinding wheels is therefore significantly shorter. In addition, the grinding wheel specification – in view of the small thickness – can be designed more specifically for the final quality. An integrated touch probe checks the diameter and length of the component after the process. A linear motor in the X-axis also ensures short chip-to-chip times because it brings the components into the machining position particularly quickly.

In addition to these exhibits, EMAG will be showcasing the new products from EMAG SU (rolling and profile grinding of gears) and will also dedicate a complete area to the topic of brake discs; here it is shown how to give coated brake discs the optimal cut.

So there is a lot to discover at EMAG at the GrindingHub.

The EMAG Group's booth can be found in Hall 9, Stand 9C41.

담당자