VM 9 - Manufacturing large workpieces with a wide variety of parts

In this webinar, you will learn how our VM 9 turning machine can increase your production efficiency and give you a competitive advantage in the production of large workpieces with a wide variety of parts.

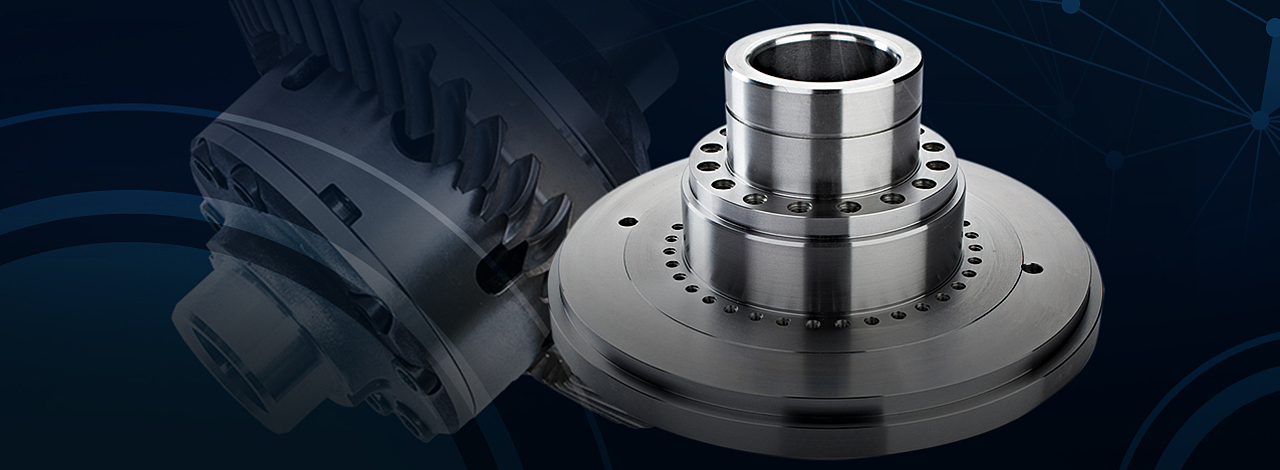

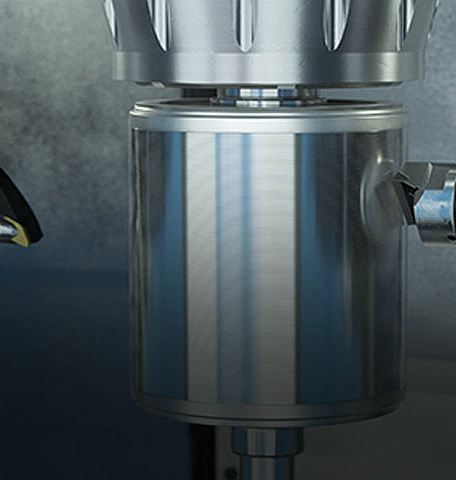

The VM 9 lathe is optimally designed for the production of smaller series and changing families of parts thanks to its bottom-spindle design. Turning, milling and drilling technologies are used for a wide range of applications. The optimally accessible work area and the bottom-mounted workpiece spindle ensure short set-up times and maximum flexibility in the production of workpieces in small series.

Why VM 9? Your advantages at a glance:

- Maximum productivity: highly dynamic axes for short non-productive times and fast machining processes

- Easy handling: all service units within easy reach

- High surface accuracy: axis control via rotary, indirect absolute encoders. All axes with fully encapsulated linear glass scale (optional)

- Highest performance through short distances

- Ideal for heavy-duty machining: generously dimensioned main spindle, maintenance-free spindle motors and rigid guideways

- Very long tool life: very rigid machine base body made of MINERALIT®, damping behavior 6-8 times better than cast iron

Find out in this webinar how the VM 9 lathe can increase your production efficiency and give you a competitive edge in the production of large workpieces with a wide variety of parts.

You might also be interested in ...

Registration Media Center