Dentatrici a creatore, verticali

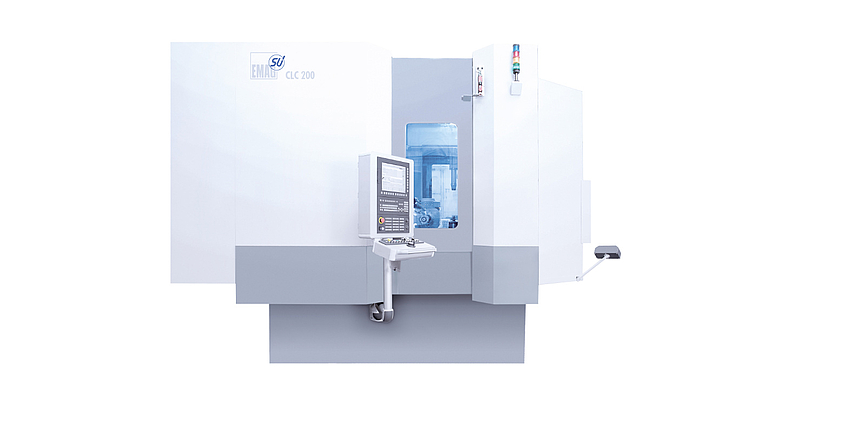

CLC Series

- Module range: mm 0 - 10

- Ø max. pezzo: 500 mm | 19.5 in

- Lunghezza max. pezzo: 800 mm | 31.5 in

CLC Series: Vertical Gear Hobbing Machines from EMAG SU

The CLC series are universal gear hobbing machines for workpieces with a diameter of 200 to 500 mm.

Highly Flexible Gear Hobbing Machines for Gear Machining of Shafts, Gear Wheels, and Worm Gears

On the innovative CLC series, gearwheels, worm gears, and gear shafts can be machined highly productively – with oil, emulsions, or dry. Several procedures are available: from hobbing and skiving to milling single parts, as well as finish milling. The standard automation system used is a 2- or 4-station ring loader with tool conveyor belt. A loading system with a robot directly on the spindle is optionally available. Additionally, the machine can be equipped with a chamfering and deburring station at the 90° position of the ring loader.

The hobbing machines are excellent solutions for machining gearwheels, worm gears, and shafts with toothing – as individual parts or as series. For larger quantities, the machine can be equipped with an automation system. On the CLC series, workpieces with a diameter up to 500 mm can be machined.

The workpiece spindle is designed as a direct drive; additionally, the tangential axis is hand scraped, and thus, contributes to the high rigidity of the machine. The high machine weight of 16 tons keeps the vibrations low during milling operations.

The workpiece table is equipped with a direct drive. With a hydraulic cylinder located in the table, clamping operations can be performed. The steady provides high pressure, which ensures that gearwheels and shafts can be clamped on the machine very securely.

Optionally the hobbing machine can also be equipped for working on non-ferrous metals.

This machine is available with either Fanuc or Siemens control. The entries are made in a dialog-based program.

Vantaggi CLC Series

- Short cycle times

- High precision thanks to stable machine with directly driven spindles

- Heavy and rigid machine

- Highly flexible, with short tooling times thanks to NC ring loader (optional)

- Automatic loading/unloading possible

- Chamfering and deburring station

Pezzi

The Right Manufacturing Solution for Every Workpiece

Tecnologie

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any…

Dati tecnici

Module range

0 - 10 mm

Ø max. pezzo

500 mm

19.5 in

Lunghezza max. pezzo

800 mm

31.5 in

| Module range | mm | 0 - 10 |

| Ø max. pezzo |

mm

in |

500

19.5 |