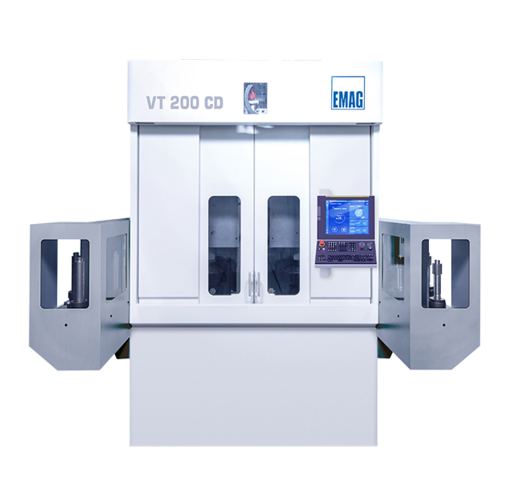

VT Series: Maximum Performance for Shaft Production

The 19" control panel with FANUC iHMI

Our 19'' control panel with FANUC iHMI was specially developed for the VL and VT vertical lathes and combines state-of-the-art technology with intuitive operation.

The advantages

1. Ergonomic design

The swivel-mounted 19'' multi-touch screen adapts to your needs. The flexible positioning enables comfortable operation and reduces fatigue during prolonged use. The large, interactive surface offers sufficient space for all important information at a glance.

2. User-friendly operation

The integrated QWERTY keyboard enables fast and precise input. The machine control panel provides direct access to frequently used functions, which significantly increases efficiency in daily operation.

3. Intuitive user interface

Our start screen clearly divides the applications into PLANNING, PROCESSING, IMPROVEMENT and UTILITY.

4. Extended functionality

EMAG-specific input and diagnostic screens optimize control and fault diagnosis. The integrated password manager enables user-defined protection levels and precision management of user rights. Machine functions can be conveniently defined and deselected via masks. The vertical shortcut bar enables quick access to important functions such as error messages, tool data and NC programs.

Further advantages

- Optimized tool management

- Integrated documentation

- Extended programming support

- Workpiece simulation

The new table view simplifies tool management considerably. Geometry shortcuts provide direct access to the tool geometry and enable quick adjustments.

Important documents ,such as maintenance manuals and circuit diagrams, are available directly on the control unit. You can also import your own documents and access them at any time.

The program editor with syntax highlighting and structured display makes programming easier. The clearly structured program manager optimizes the management of NC programs. The G-Code Guidance supports you during parameterization and when inserting machining cycles.

Rotate the workpiece freely around 3 axes and use the option of manual measurement within the simulation.

![[Translate to Italian (5):] [Translate to Italian (5):]](https://cdn.emag.com/fileadmin/_processed_/5/3/csm_vt-2_preview_c1d1c8ae4e.png)

![[Translate to Italian (5):] [Translate to Italian (5):]](https://cdn.emag.com/fileadmin/_processed_/9/5/csm_vt-4_preview_80b54809d2.png)