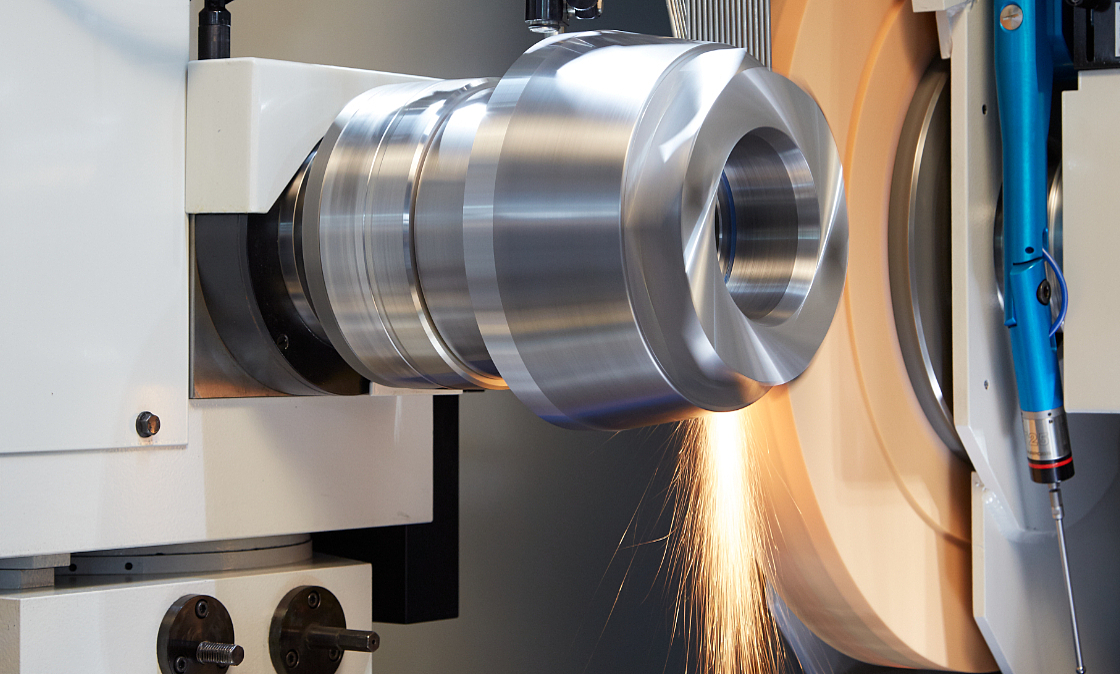

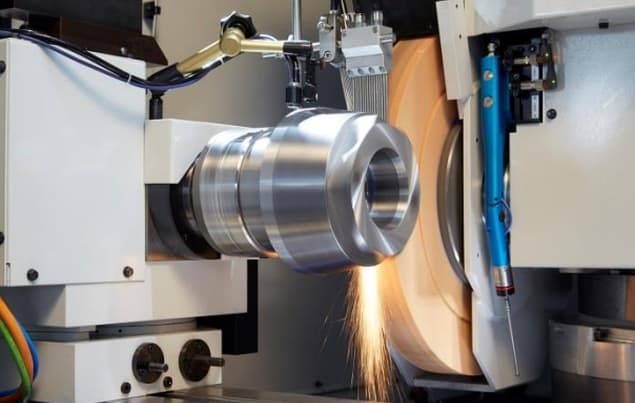

Universal Cylindrical Grinding—External and Internal Cylindrical Grinding

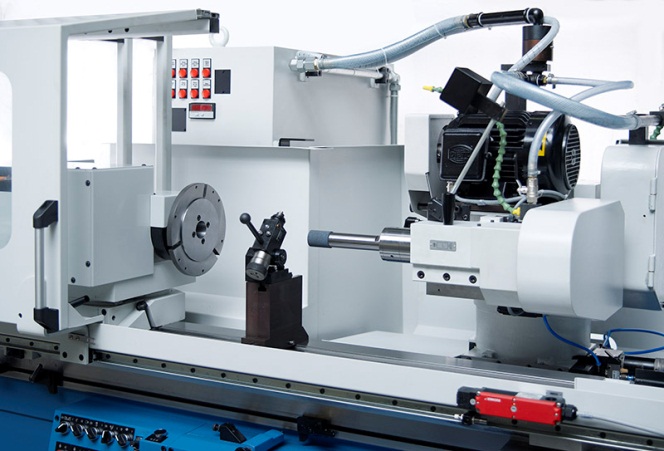

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external cylindrical grinding the workpiece is usually clamped between tips. The infeed of the grinding tool is then machined conventionally or CNC-controlled.

Universal Cylindrical Grinding: Conventional or CNC-Controlled

Conventional cylindrical grinding refers to manual adjustment of the grinding machine, including grinding, adjusting, and measuring the grinding work. While the number of CNC grinding machines used keeps growing, conventional cylindrical grinding is still the method used for single parts or prototypes.

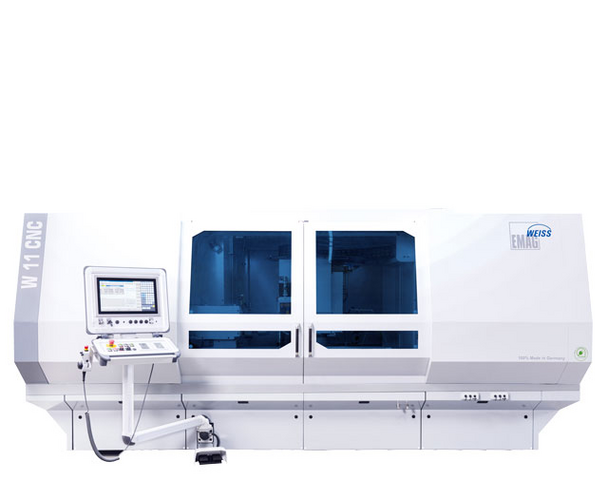

As the term CNC cylindrical grinding suggests, the grinding process is adjusted using CNC programs. This allows for significantly faster machining times, since the workpiece just needs to be changed before loading the corresponding program into the CNC control unit. The rest is done automatically, which is why CNC universal cylindrical grinding is used for frequently recurring grinding work – ex. for mass production or to manufacture families of parts.

When deciding between conventional or CNC-controlled grinding, the question always boils down to the grinding task. However, since many users manufacture both single parts and series, the only right choice is a universal cylindrical grinder, as it enables both conventional grinding and CNC grinding.

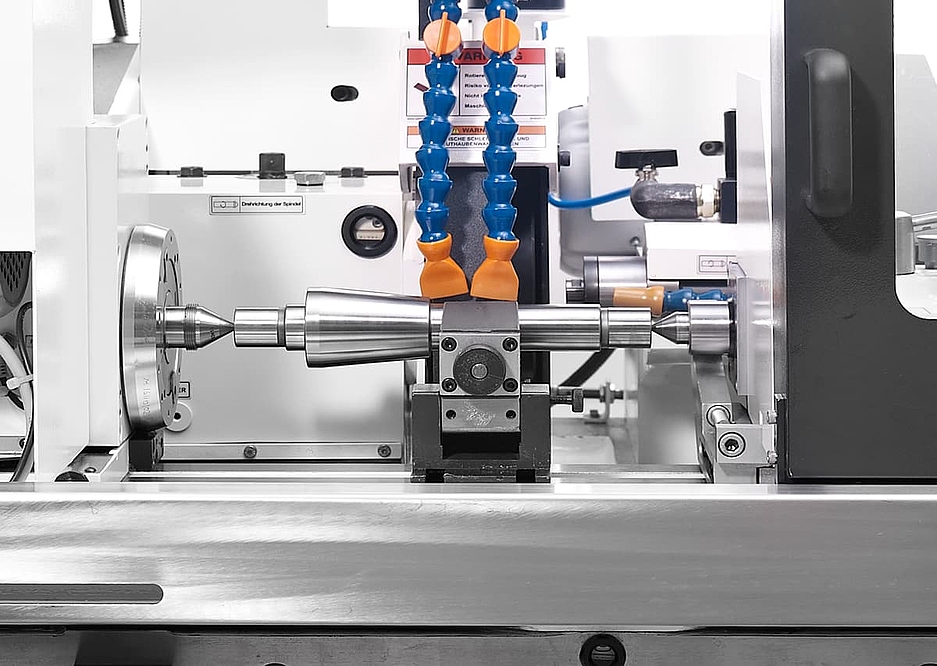

EMAG Weiss has an interesting solution for this with its W 11 CNC, for example.

Universal Cylindrical Grinding with EMAG Weiss

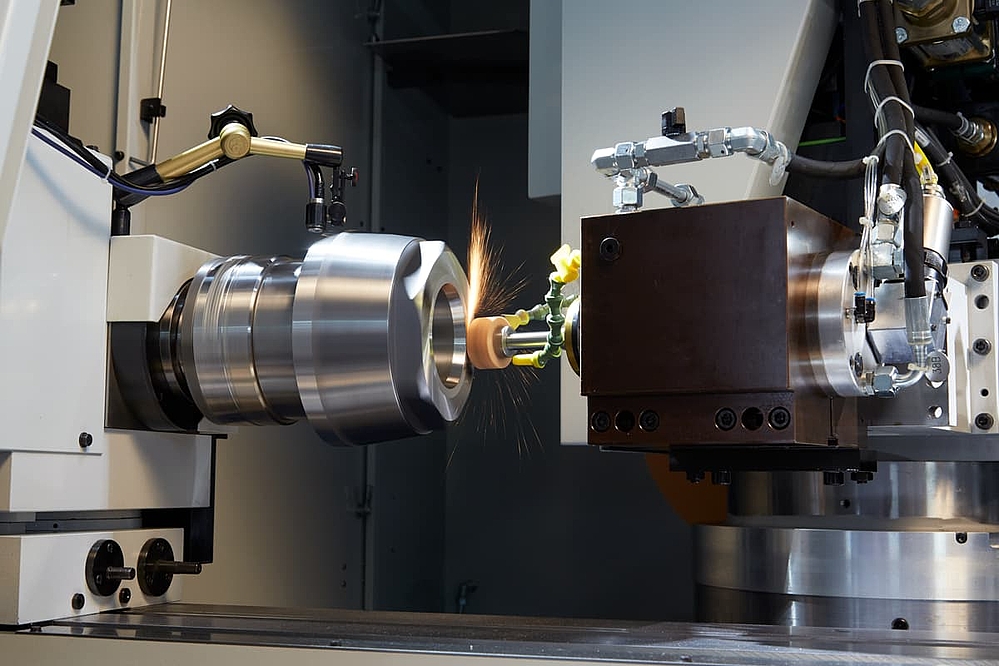

EMAG Weiss is known for high-end technology in universal cylindrical grinding between tips. From the ECO 200 for a manual grinding process, to the CNC-controlled machines WUG 21 or W 11, to the production grinders W 27, W 37 and W 50 including automation, EMAG Weiss offers the perfect solution for nearly every user.

Universal Cylindrical Grinders for Nearly Every User

All EMAG Weiss cylindrical grinders feature the latest grinding technology and subassemblies developed in-house. Upon request, an existing Karstens machine base can be used to build a new machine on top of it by retrofitting. EMAG Weiss offers both cylindrical grinders developed and built in-house, as well as classic retrofitted machines that are assembled like new. The wide range of services that EMAG Weiss provides includes grinding technology development, mechanical and electronic design, and construction of universal grinders, as well as, the development and programming of the control interface and user software.

Machines for your requirements

(4) machines found