Profile Grinding: for Internal and External Teeth

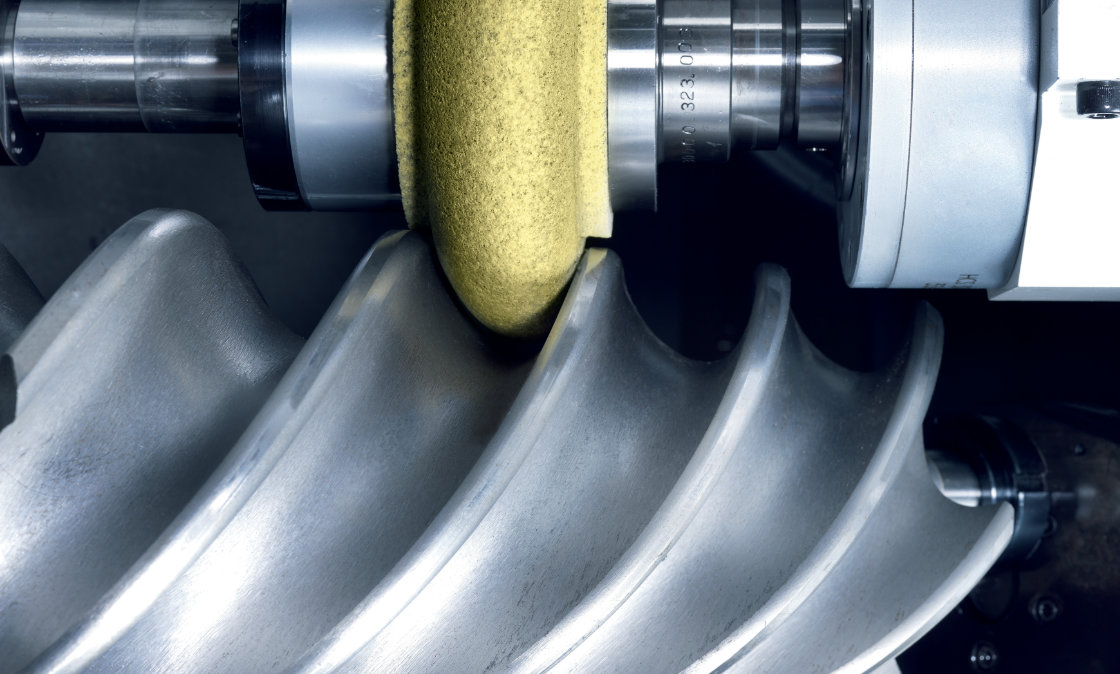

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the other. Electroplated CBN grinding wheels, dressable CBN grinding wheels or ceramic dressable grinding wheels can be used for this purpose. Dressable grinding wheels are dressed on the machine.

Highly Flexible Profile Grinding: Frequently the Best Choice, Even for Workpieces with Interfering Contours

For the profile grinding of gears, a profile grinding wheel is used to grind a tooth gap. After one gap is finished, the next gap of the component is ground until all teeth have been machined. The CBN grinding wheels are highly productive and have the desired tooth gap shape.

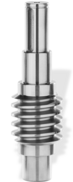

Dressable grinding wheels are normally used for high flexibility. All possible profile shapes that can be described using XY coordinates can be dressed. In addition to gears, rotors, spindle pumps and worms can also be machined, for example. Both internal and external gearing can be ground, even with very small grinding wheels.

Even very long components, such as extruder shafts, ball screws, trapezoidal thread spindles, etc. can be machined. Grinding from the solid material is an alternative if, for example, no tools are available for pre-cutting gears. A dialog software is used to enter the necessary data.

The benefit of profile grinding is the high quality and high flexibility. This does not only refer to the profile shape, but also to the machining of components with interfering contours using small grinding wheels.

Advantages Profile grinding

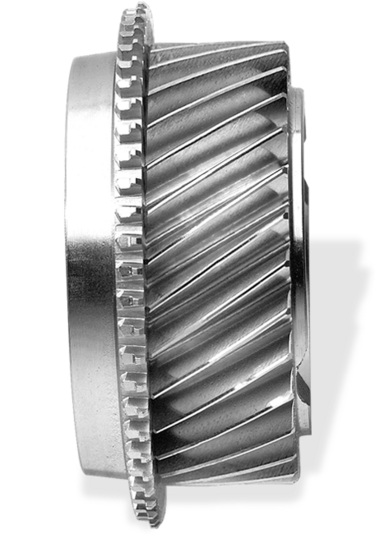

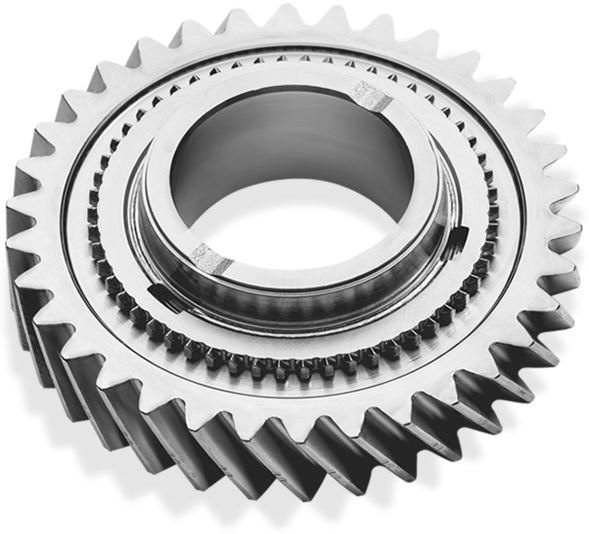

- Universal: Profile grinding can be used to machine a very large number of geometries – including external and internal toothing

- Precise: The high-precision profile of the grinding wheel matches the desired production profile.

- Flexible: Corrections and special profiles can be done quickly.

Workpieces

The Right Manufacturing Solution for Every Workpiece

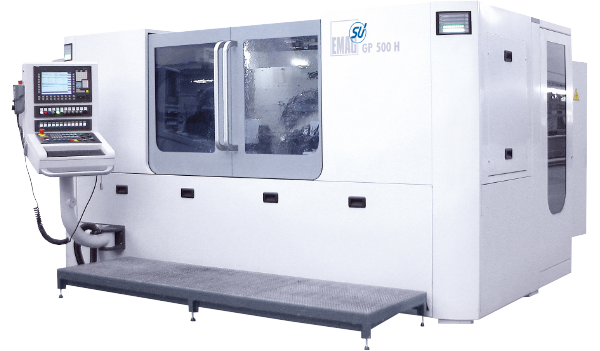

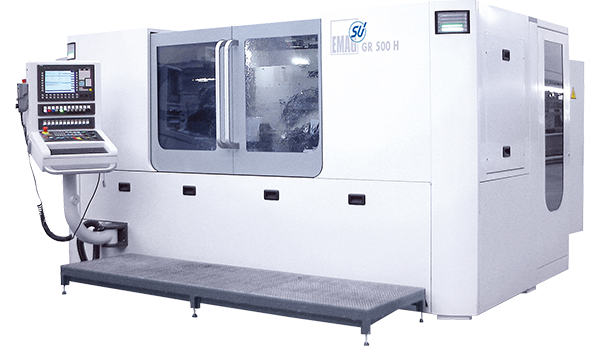

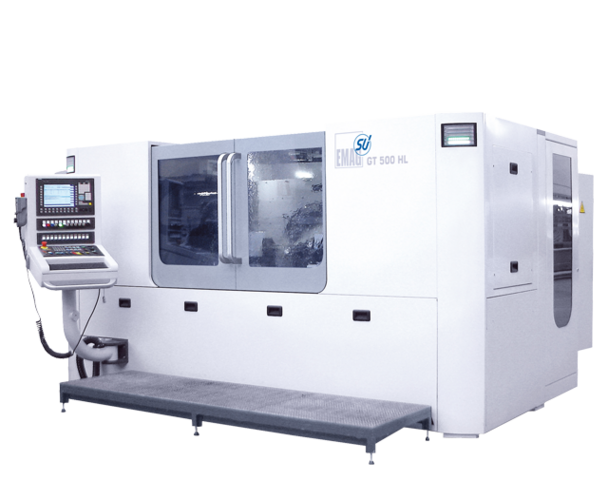

Machines for your requirements

(10) machines found