Power Skiving for the Highly Efficient Production of Gears

Power Skiving allows highly efficient machining of chucked parts and gears. For the machining of internal teeth hobbing, it provides an alternative to broaching and gear shaping. One outstanding feature of this high-performance process is that it can be run with high cutting speeds.

Power Skiving of internal teeth hobbing – the alternative to broaching and gear shaping

The power skiving method for gear production is highly efficient due to its continuous machining sequence, making it an effective alternative to broaching and gear shaping. However, the machine and tool must be matched perfectly in order to ensure the highest quality. EMAG offers power skiving as a supplementary technology module for its CNC turning centers. For both internal and external teeth hobbing, this means higher productivity and quality in pilot series and medium-volume production, and more flexibility due to the universal use of the machine.

The power skiving method is a combination of gear hobbing and shaping by continuous hobbing with axial feed. In theory, the method is not new. However, it is still considered a high-performance process because it allows for high cutting speeds, and significantly more teeth are engaged per time. This is made possible by the angled axis arrangement of tool and workpiece. While gear hobbing is based on worm gears, power skiving is based on a helical wheel gear.

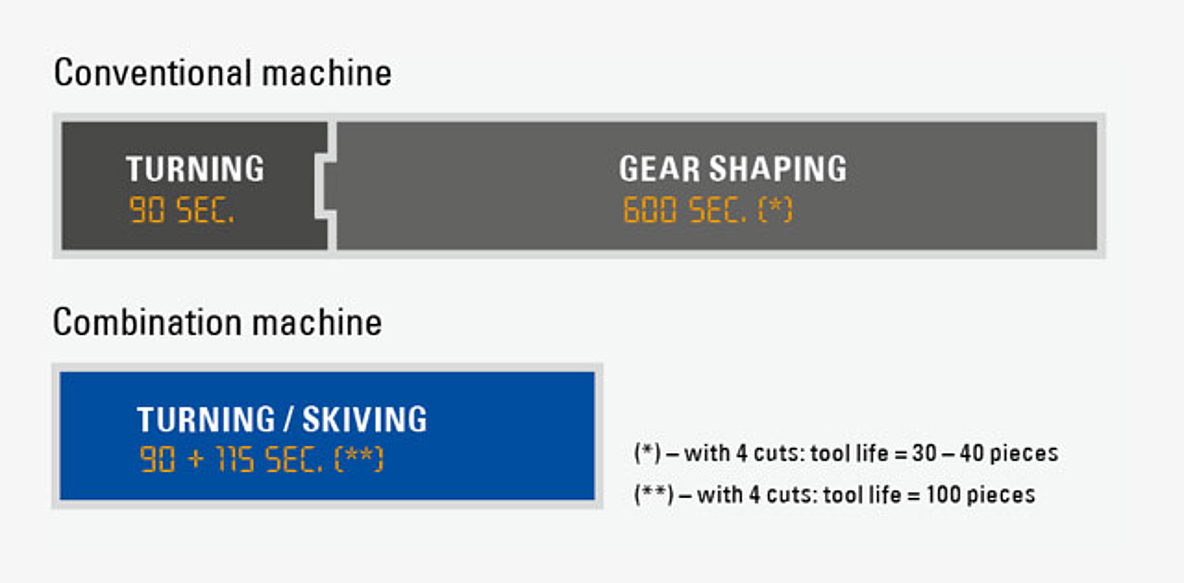

Power skiving is the method of choice for one-off to medium-volume production. Power skiving is particularly attractive for the machining of internal tooth hobbing that was previously produced by broaching or gear shaping. Compared to gear shaping, the power skiving method provides 2 to 3 time’s more productivity and tool life. Another advantage of power skiving is the fact that both rough-machining and finish-machining can be done in one clamping operation. Including the turning process in the same clamping operation prevents re-clamping errors, and is an effective way to eliminate radial deviations.

Interesting to know

The process of hard-finishing hardened gears with the power skiving method using carbide tools has only been possible since the mid-1980s. Advances in machine technology with the electronic gear train have resulted in a more precise maintaining of the transmission ratio between tool and workpiece, while the speeds in the generating train could be increased. In the meantime, a "consortium" consisting of tool and machine manufacturers and coating, control unit and measuring center suppliers have been focusing on the subject.

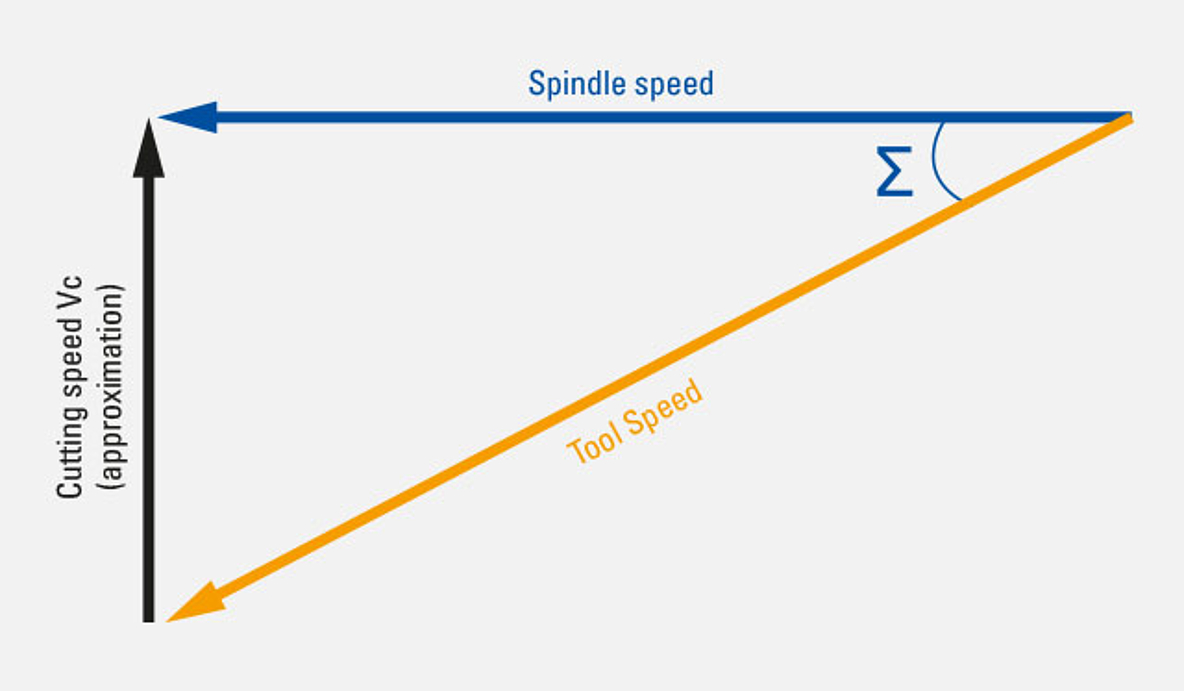

The Power Skiving Principle

Influence on cutting speed Vc:

- Workpiece speed

- Ratio ∅ workpiece / ∅ tool

- Axis crossing angle Σ, common values are between 15° and 25°

Advantages Power Skiving

- Higher quality: Rough machining the crown circle diameter and subsequent toothing in one clamping operation

- High productivity: Faster machining compared to traditional turning and gear shaping

- Easy handling: No parts logistics between operations

- Increase in productive time: No extra loading time needed

- In one clamping operation: Pre-turning and toothing in one clamping operation

- High flexibility: Fast, continuous machining of internal and external toothing, also against a flat collar or with undercut

- Universal use: Both straight and helical toothing are possible

Machining task of turning and toothing a helical toothing

Workpiece parameters

Diameter d1 [mm] 70 (internal)

Number of teeth z1 86

Helical angle ß [°] 20

Module [mm] 0.8

Material 42CrMo4+QT

Machines for your requirements

(2) machines found