High Volume Brake Disc Production: High-Productivity Laser Metal Deposition for Efficient Processing

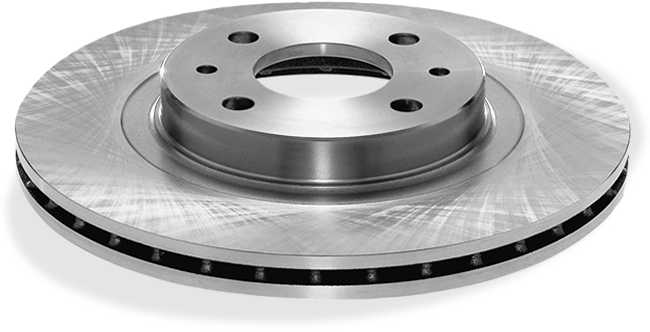

Euro 7 standard mandates lower non-emissions particulate matter - the previous passenger car brake disc is to become obsolete and discontinued model. For the new generation of brake discs, EMAG, along with its technology partner HPL Technologies offer a complete solution for the hard coating of brake discs by laser metal deposition – the process is safe, efficient, and fast.

Laser Metal Deposition: Focus on the Perfect Surface

1. The Background: New Euro Emissions Standard

Today's passenger car braking systems generate (too) much particulate matter and thus harm personal health, according to experts and the EU Commission. In this respect, the planned Euro 7 emissions standard features major changes: The permitted amount of particulate matter will be massively reduced - creating a cost-effective advantage for hard coating of brake discs. Their decisive advantage: the conventional brake disc simply gets a new coating that offers protection against corrosion, wear, and fine dust.

2. The Solution: Proven and Scalable Production

In principle, coated brake discs are nothing new, but they have so far only been used in niche markets due to high production costs. In this context, the combination of EMAG mechanical engineering and WECODUR technology from partner HPL Technologies represents a quantum leap forward the new production solution is tried and evaluated, easily capable of high-volume production and, furthermore, economical!

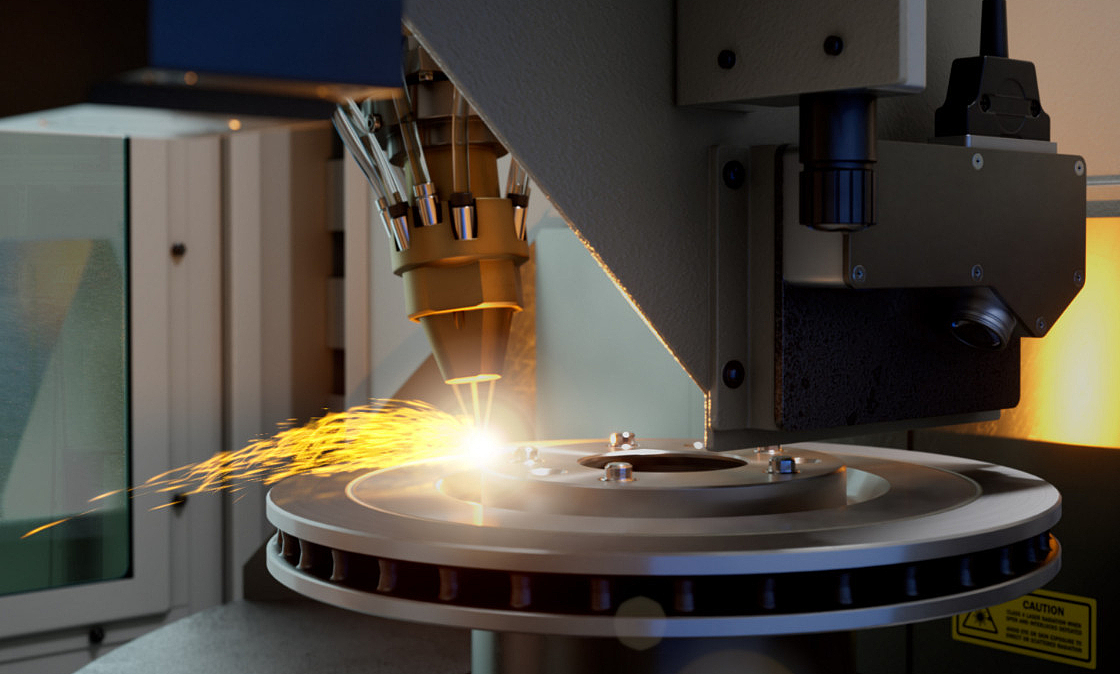

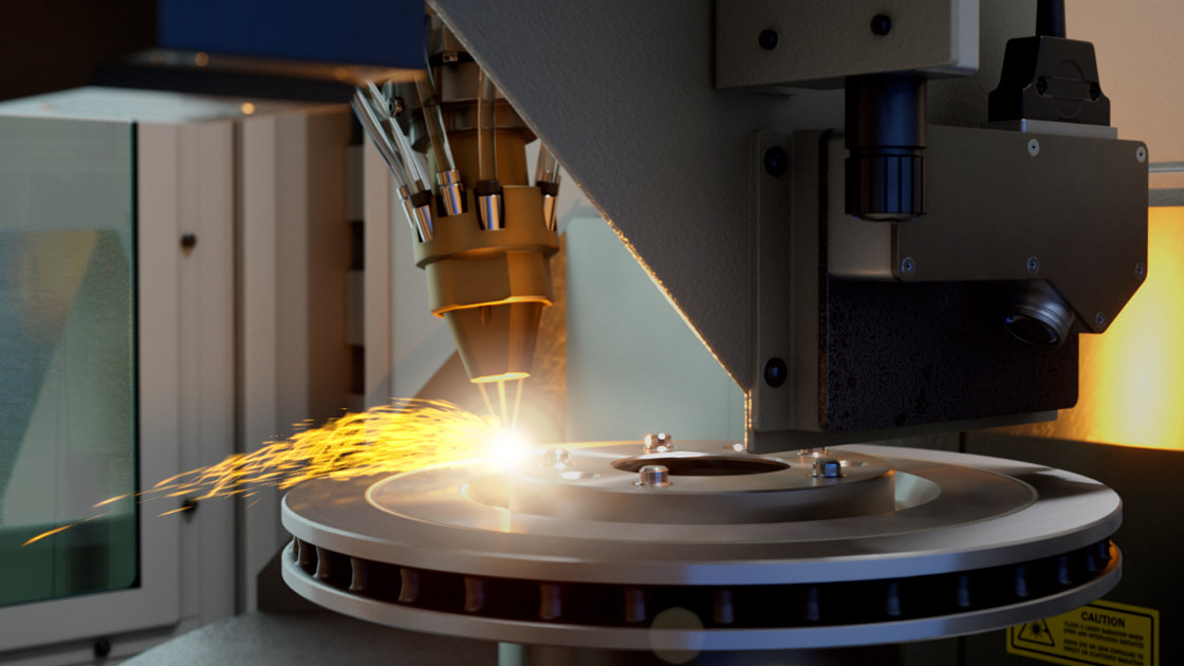

3. The Technology: An Additive Process

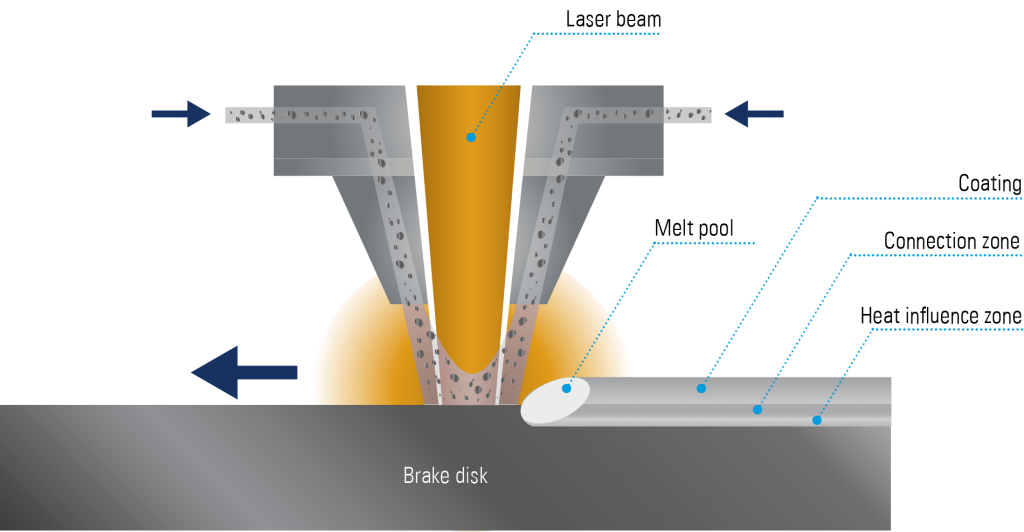

The basis is what is known as DED (Direct Energy Deposition) technology, specifically high-speed laser metal deposition. In this process, the material powder is directed into the focus of the laser beam, where it melts while still in the air and hits the corresponding melted surface of the brake disc. Among other things, this is important for economic efficiency:

- WECODUR laser metal deposition ensures a large area rate (over 5 m2/h), a minimum layer thickness (down to less than 0.05 mm) and a homogeneous surface.

- The technology is used in a proven machine, the ELC from EMAG LaserTec, which includes either two (DUO) or three (TRIO) rotary tables and an in-machine handling system.

The blank disc is turned beforehand, and after coating only cooling and grinding are required. The latter is conducted by double-side face grinding, which enables highest feed rates at high efficiency. These processes can be fully fine-tuned with EMAG technology.

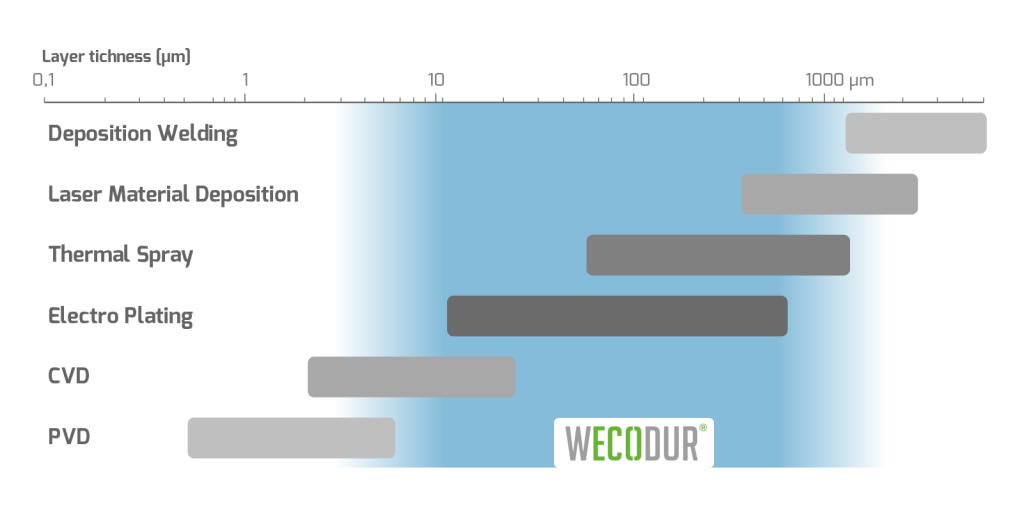

4. Comparison: Avoiding Disadvantages

Alternative technologies such as thermal spray and electroplating do not produce a metallurgical bond to the base material. Like laser cladding does. Consequently, complex pre-machining operations are necessary to bond the layer. Additional advantages of the EMAG/WECODUR technology include significantly higher powder delivery efficiency, considerable reductions in process gases and CO2, and lower grinding costs.

5. Conclusion: Everything from a Single Source

On request, the complete manufacturing solution for large-scale, high-volume production of the next generation of brake discs can be supplied from a single source. Customers benefit from extensive process knowledge, proven technology and experience on tried-and-tested coating systems.

Incidentally, Laser Metal Deposition of Brake Discs also supplies a major benefit for e-mobility. Electric vehicles rarely use their brakes as sufficient braking effect is already generated during engine recuperation. As a result, the seldom used brake disc begins to rust, especially under winter conditions. Hard coating of brake discs solves this problem.

Advantages Laser Metal Deposition

- Perfect: Further development of laser metal deposition enables the production of thin and homogeneous layers down to less than 0.05 mm

- Variable: Wide range of material combinations possible

- Safe: Closed-loop process chain enables economical large-scale production for the first time

- Fast: Large coverage area rate up to over 5 m2/h

Workpieces

The Right Manufacturing Solution for Every Workpiece

Machines for your requirements

(2) machines found