Hobbing: Highly Productive Manufacturing of Gears, Gear Shafts, Worms and Rotors

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any gear shapes, numbers of teeth and spiral angles to be produced. With profile milling, rotors and screws can be manufactured in a highly productive single-part process.

Hobbing and Profile Milling in Detail

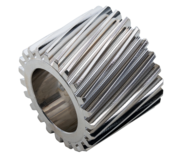

The basic principle of hobbing is to roll the tool over the workpiece. Many teeth of the tool are used, which makes this process highly productive. By tangentially moving (shifting) the tool, new areas of the tool come into use continually, so that large numbers of workpieces can be produced between the resharpening process of the tool.

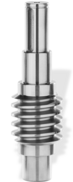

With single-part milling or profile cutting, the side milling cutter has the shape of the tooth gap and mills every gap/thread of the toothing or worm. Then, the right spacing is applied and the milling process starts again to produce the next gap. This can be used for the rough milling of large tooth gaps or also for worms and rotor milling.

On the machines, both dry machining and wet machining with emulsion or oil cooling lubricant are possible.

All machines are CNC-controlled and are equipped with a directly driven table and a milling head. They are also characterized by high rigidity and a high machine weight, which has a vibration-damping effect on the process.

Vertical and horizontal hobbing machines from EMAG SU

Vertical hobbing machines

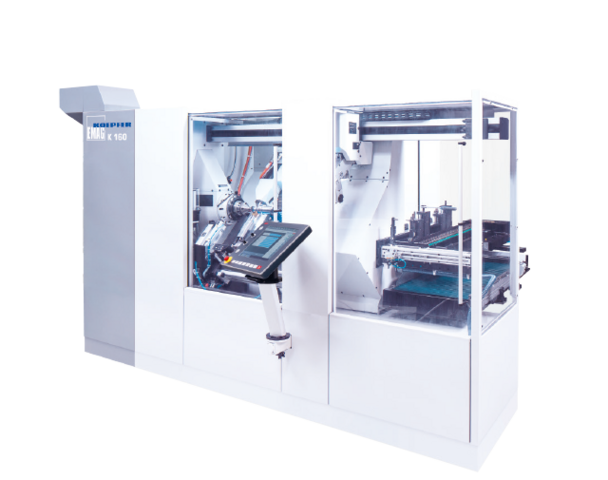

The vertical hobbing machines can be equipped with an NC-controlled 2- or 4-station ring loader. Loading using a robot is also possible. Deburring and chamfering units are also optionally available. Skiving, finish milling and the machining of non-ferromagnetic workpieces with additional options are also possible. Gears, gear shafts and worm gears can thus be produced cost-effectively on these machines.

Horizontal hobbing machines

Thanks to the horizontal workpiece axis, these machines offer outstanding set up possibilities. They are suitable for gear cutting and long shafts and are therefore highly flexible. Loading can take place manually or with an automation system.

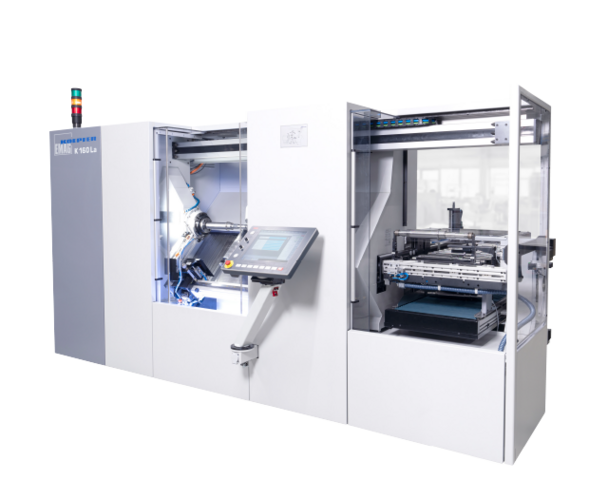

Horizontal profile milling machines:

These machines are specially designed for the machining of worms and rotors and have high torques on the table and milling spindle drive. A side milling cutter is used to cut the gear tooth gap. HSS and carbide indexable insert cutters can be used. These machines are capable of machining both high profiles and long workpieces.

High flexibility during gear milling

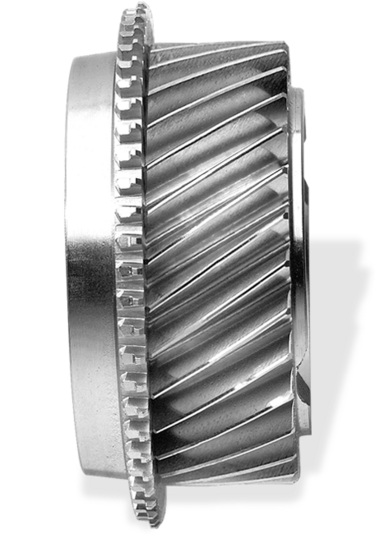

An outstanding benefit of gear milling is its high flexibility in the production of external toothing: different workpieces with any number of teeth, different profiles and helix angles can be produced - with high productivity.

Advantages Hobbing

- Versatile: Any tooth shapes, helix angles and gear widths can be produced.

- Productive: Uninterrupted cutting with many cutting edges ensures short cycle times.

- Precise: The highly rigid machine design allows gearing to be produced with high precision.

Workpieces

The Right Manufacturing Solution for Every Workpiece

Machines for your requirements

(6) machines found