Gear Shaving – The Perfect Gear Surface

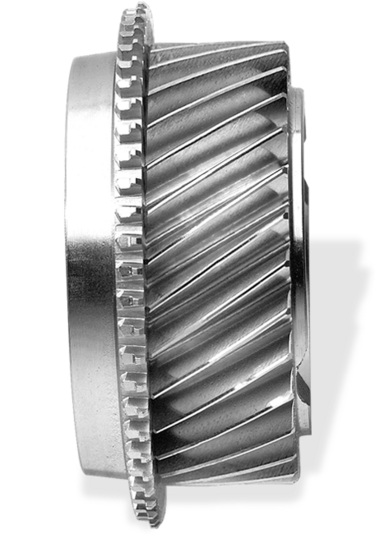

Gear shaving takes place before the hardening process and is a cost-effective process. It results in low-noise gear surfaces - a major benefit that the automotive and supplier industry takes advantage of, for example.

Gear Shaving – Low-Noise Surface

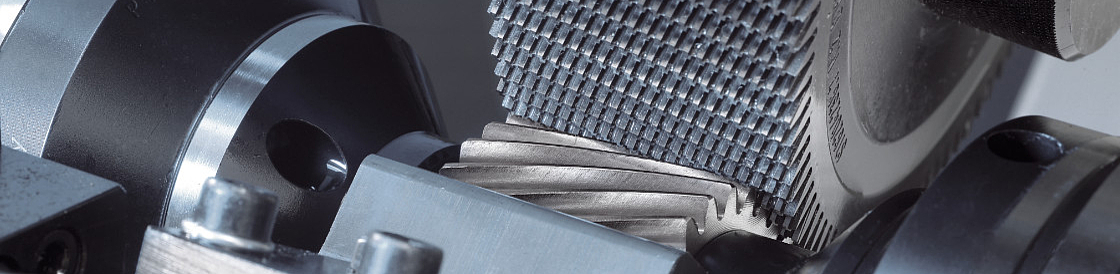

During the process on the EMAG SU machine, the workpiece and the shaving cutter form a gear pair with axes that are rotated relative to each other (axis cross angle). This positioning results in sliding between the shaving cutter flank and the workpiece tooth flank. It is also important that the tooth flanks of the shaving cutter have small grooves that act as cutting edges. And because the process takes place before the hardening process, any hardening distortions are processed by the shaving cutter.

All common shaving methods possible

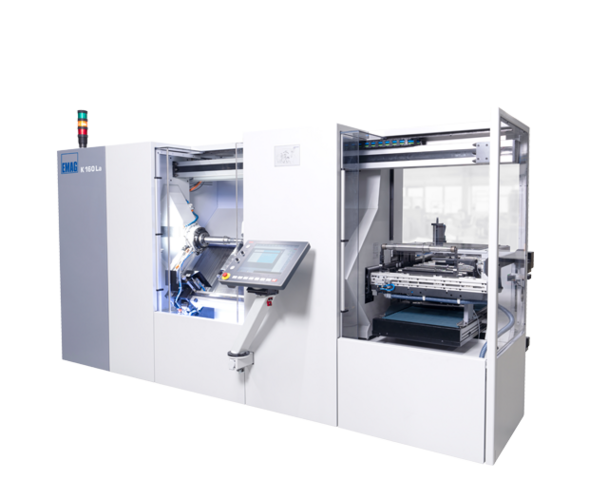

For this reason, shaving requires extremely precise machines and tools. The shaving machines from EMAG SU have a modular design and are configured with three, four or five NC axes. On this basis, all common shaving methods - such as "plunge", "parallel", "underpass", "diagonal" and "combined cycles" - can be used. Another benefit: The crowning/conicity of the machines is provided by a table rocker, which eliminates the need for complex gears in the machining head. In addition, the machines are very rigid and versatile. For example, deburring, oil centrifuging, marking and optical component detection are also available as options.

The productivity of a gear shaving machine is generally higher than that of a grinding machine - and with good quality, because shaving produces low-noise gearing. As a result, gear shaving is still a frequently used process in the automotive industry. It results in reduced production costs (compared to grinding).

Advantages Gear shaving

- Fast: Shaving is very productive and provides good value for money.

- Qualitative: Shaving produces low-noise gearing.

- Controlled: Shaving ensures consistent results with minimal variance, even when machining large quantities.

Workpieces

The Right Manufacturing Solution for Every Workpiece

Machines for your requirements

(4) machines found