Oilfield Industry

EMAG offers machines and complete manufacturing systems for the oil field industry. With over 40 years of experience in the machining of oil field components – such as tube ends and couplings, tool joints, drill bits and rock bit cones, pump impellers and pump housings – the name EMAG stands for highest quality and reliability in the use of cutting-edge technologies.

Complete manufacturing systems from a single source

Today, production lines for the machining of tubes, coupling sleeves and caps cover a variety of manufacturing processes.

Apart from CNC machines for threading work, there are automatic circular saws, hydraulic presses producing raw parts for thread protectors and nipples, washing machines for coupling sleeves, loading pits for tube bundles, mandrel test facilities, collection pits for tube rejects, tube storage lines, stations for visual thread inspection, non-destructive tests, coupling sleeve assembly lines, stations for the fitment of thread protectors and nipples, automatic test presses, coating machines, dry beds, length measuring systems, weighing stations, embossing stations, ring marking devices, stacking and bundling facilities and last, but by no means least, the central control system for the whole process.

Customized solutions for the complete-machining of couplings and tool joints

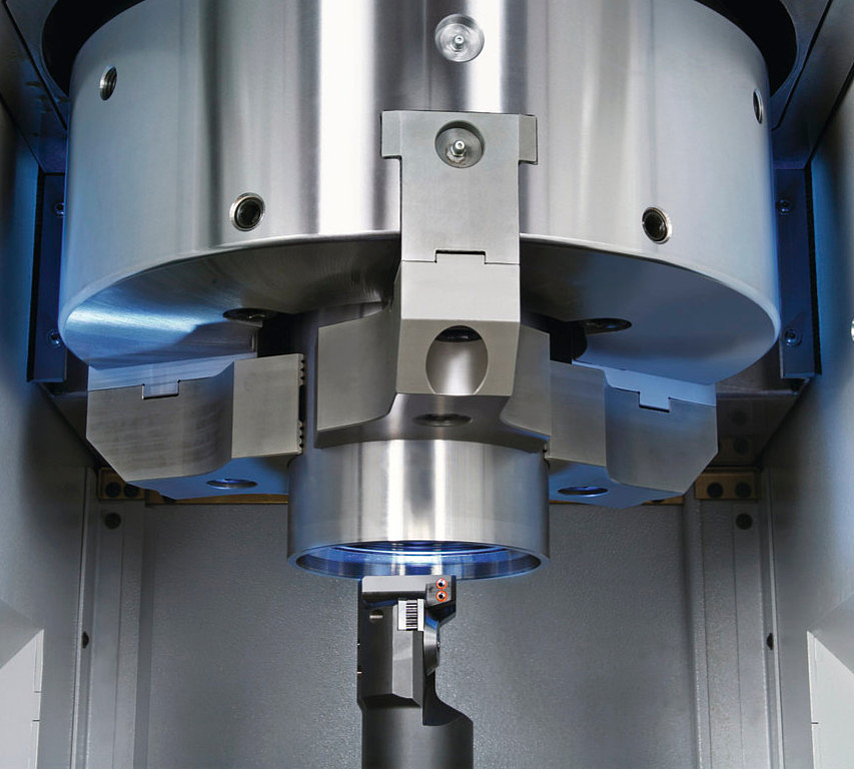

EMAG uses a wide range of vertical turning and center drive machines in order to achieve this customization. Manufacturing system configurations are engineered to suit individual machining requirements and ensure a high degree of operating efficiency. When components are produced on vertical turning machines the pick-up spindles ensure that the machines load themselves. The key advantage of these machine and system concepts are the short traverses, which lead to the shortest possible work handling and machining times.

Coupling sleeve machining centers