Retrofit from EMAG: Tailor-made solutions for every task

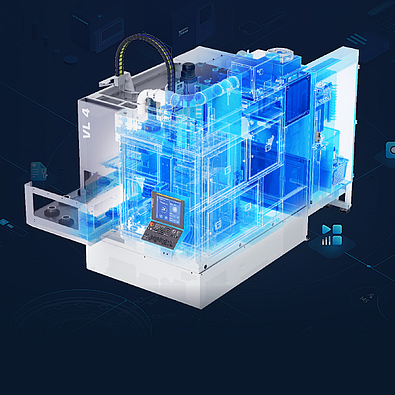

Cost-effective, sustainable and at the same time custom-fit production solutions based on used machines - this is how the advantages of EMAG Retrofit could be summarized. In many cases, the performance of the modernized machines even matches that of the new models. What's more, they can be equipped with additional technologies on request.

Used machines fit for the future

With the knowledge gained from over 25 years of successful retrofit projects, EMAG makes your machine fit for the future. EMAG machines are perfect for retrofitting, thanks to their robust Mineralit polymer concrete base, which ensures long-term reusability even after the machine has been rebuilt.

What else is implemented depends on the user's wishes:

The whole thing ranges from:

- A complete mechanical and electrical rebuild of the machine via the integration of additional tool processes or IoT technology

- To minor modifications such as the integration of a new clamping cylinder (or similar).

In addition, EMAG buys old machines, upgrades them with new technologies and offers them on the market again. Tailor-made retrofit solutions are, therefore, also available “from stock.”

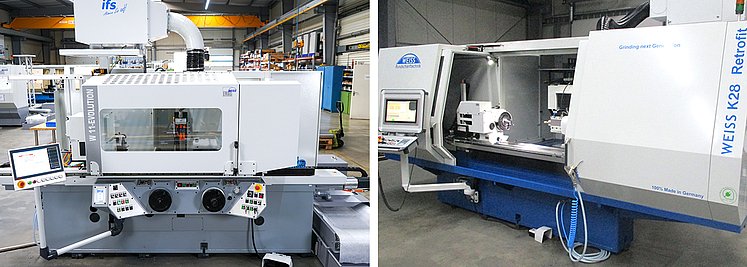

Retrofit expertise for grinding machines from the EMAG Group

EMAG also offers comprehensive expertise in the field of grinding, from external cylindrical grinding to internal cylindrical grinding and out-of-round grinding. We offer customized modernization and retrofit solutions for EMAG and Weiss and Karstens cylindrical grinding machines - from mechanical overhauls to complete technology upgrades.

Comprehensive modernization concept for your grinding machine:

- Complete mechanical overhaul of all components

- Integration of the latest CNC control technology

- Reconditioning of scraped guideways

- Upgrade the drive technology to servomotors

- Modernization of the hydraulic components

- Implementation of current security technology

- Process optimization and technology consulting

Integrating new technologies

Various examples from the field of VSC lathes show what you can expect from the rebuilding of a machine. At the customer's request, these "perennial favorites" were also converted into turning and grinding centers during the retrofit. This reduces machining times and allows for greater flexibility in handling diverse production tasks.

Sustainable and digital solutions

The retrofit is also appealing in the context of addressing key future topics, such as incorporating IoT and increasing sustainability. With EDNA, EMAG has a turnkey IoT technology that can be integrated into more modern existing machines (depending on the control system installed).

The same applies to "retrofitting" for greater sustainability: the retrofit experts analyze the existing production solution, identify unnecessary "energy guzzlers" and implement more economical processes.

Advantages

|

Technical Hotline

Our technical hotline records all inquiries and gives you technical assistance

+49 7162 17-4300

service.salach@emag.com