IMTS 2022 Highlights

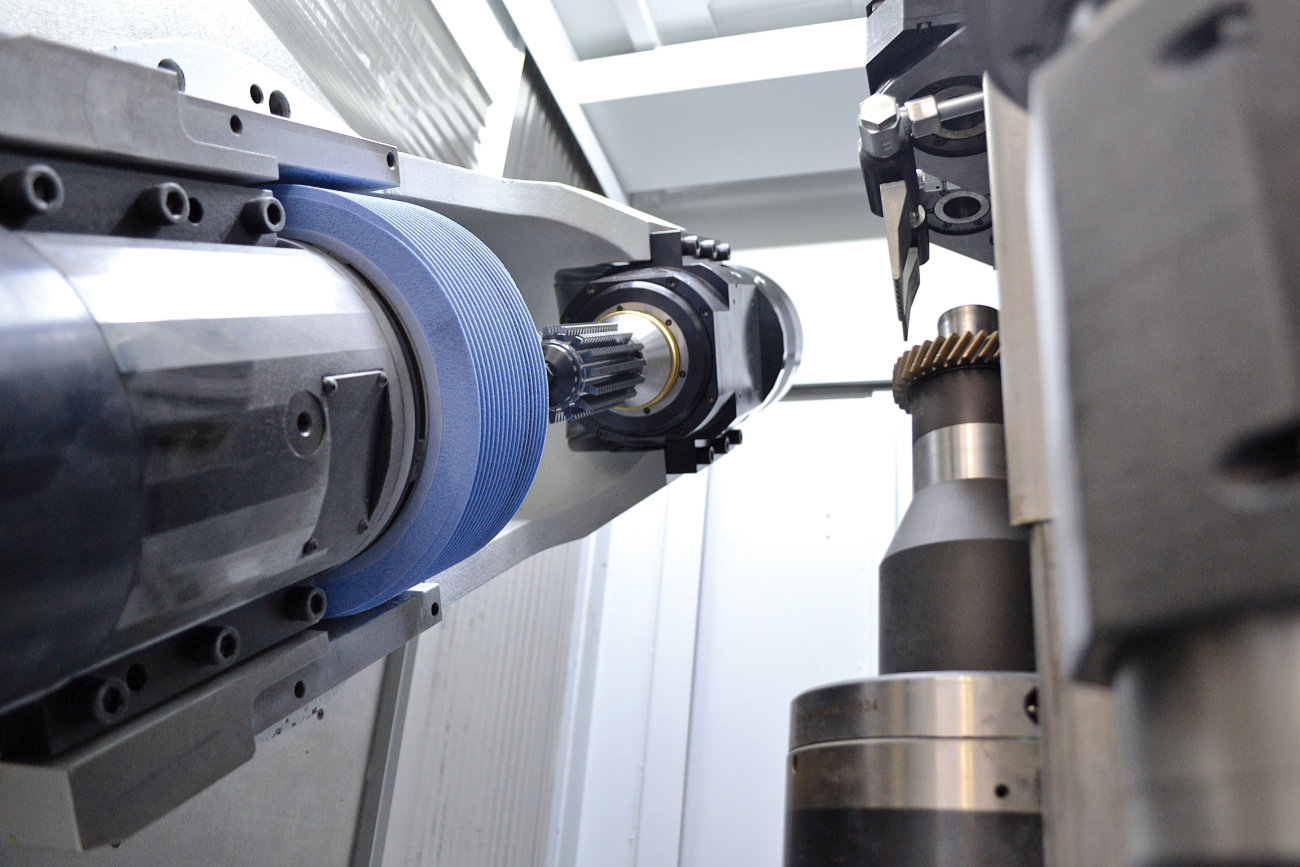

SG 160: Dry Grinding Gear Wheels for Maximum Efficiency

Rising energy costs make processes such as dry grinding very interesting as most energy in conventional gear grinding is used to treat the cutting fluid.

In the first stage of the process, this SG 160 uses a skiving hob to remove the majority of the oversize on the tooth flanks of hardened and pre-cut gear wheels. The second stage is then generating grinding. Both stages are carried out in completely dry conditions.

More information

Digitalization @ EMAG – The future is connected

Watch demos of EMAG’s VL 4 and VT 4 turning machines equipped with EDNA in our booth. Both the VL 4 and the VT 4 turning machines include automated loading and unloading options as well as EMAG’s EDNA Human-Machine Interface (HMI). Ask how EDNA can increase productivity and dramatically reduce costly downtime and expensive repairs or the need for equipment replacements.

More about our EDNA IoT Products