16/08/2023 - Oliver Hagenlocher - Press

VSC 400 PS: New standards in efficiency and precision for gear production

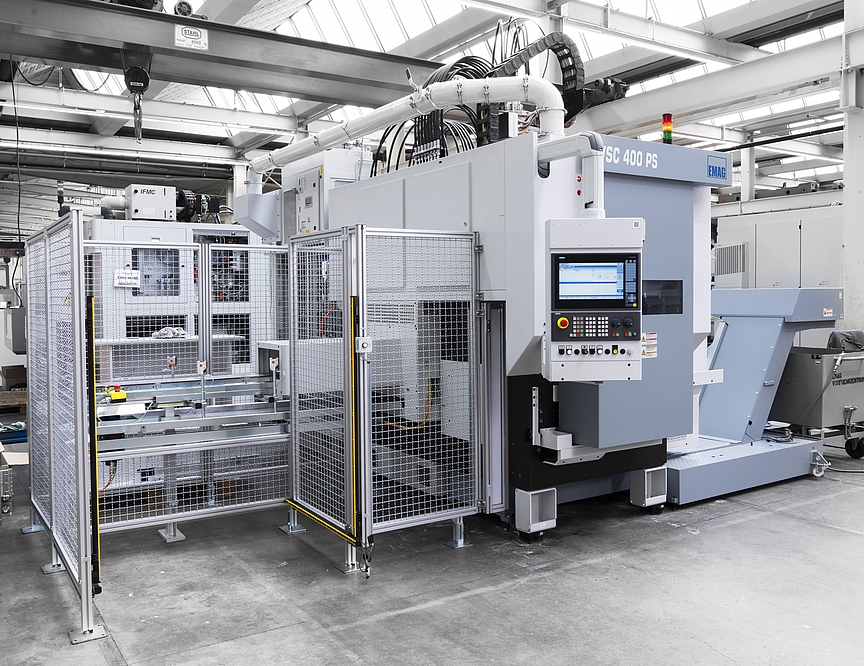

EMAG presents its latest development at the EMO trade fair, from 18 to 23 September 2023 in Hanover: the VSC 400 PS. It combines power skiving and turning for complex gear solutions, making it a game changer in gear production.

Images

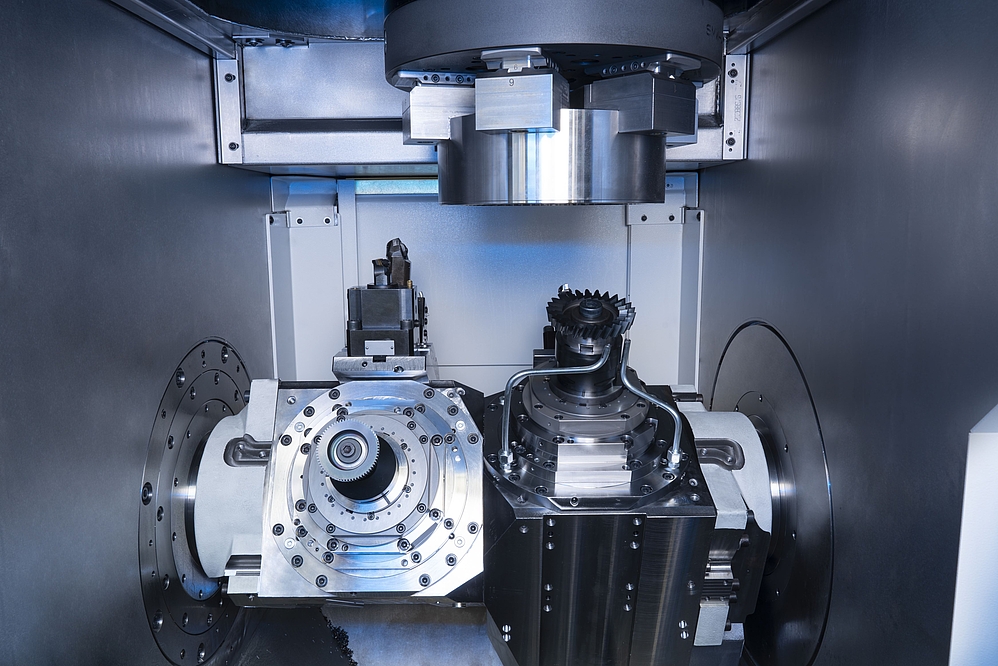

The VSC 400 PS opens new possibilities for users in gear production. It makes power skiving, a process known for its speed and flexibility, easier and more accessible. With the ability to equip the machine with up to four power skiving tools and six turning tools, users can produce complex components safely and efficiently in a single setup. This saves time and improves process reliability - a decisive advantage in gear production, where precision and speed are of paramount importance.

For many applications, especially in electromobility, gear manufacturing and hydraulics, the VSC 400 PS offers an optimal solution. It outperforms conventional processes such as gear shaping and hobbing in terms of speed and flexibility and enables the production of internal and external gears with high precision and speed. The combination of different processes in a single machine also brings a variety of benefits for users. They can perform both rough-machining and finish-machining in one setup and in one machine in quick succession, which minimizes the overall machining time and saves capital investment.

The VSC 400 PS is designed to machine components with a maximum diameter of 340 millimeters and a maximum height of 420 millimeters. It offers numerous technical advantages, such as perfectly synchronized axes during the machining process and a wide variance of axis cross angles. The robust design ensures accuracy, while hydrostatic guideways dampen vibrations, resulting in longer tool life.

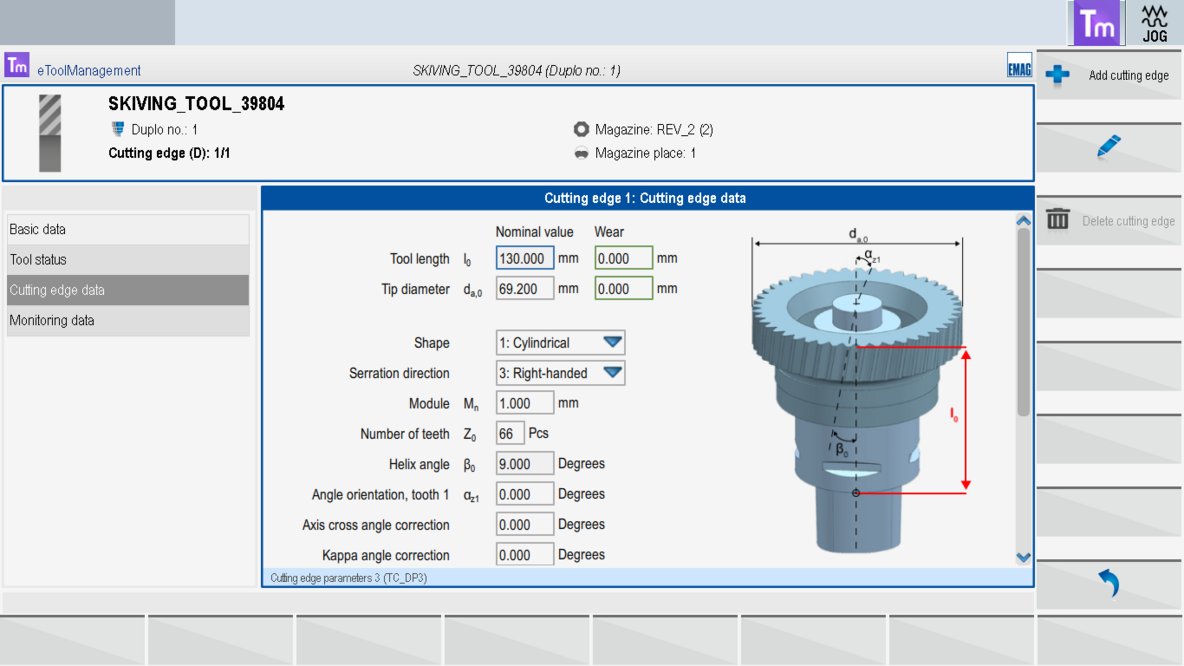

The intuitive user interface of the VSC 400 PS makes operation extremely simple. Users only must enter the desired gear values, the values of the tool data sheet as well as the cutting values and the machine calculates the entire machining programme for the hobbing process independently. In addition, the VSC 400 PS supports the operator with interactive images and automatic safety prompts.

Finally, EMAG's comprehensive ecosystem EDNA offers efficient IoT integration of the machine. It enables data recording, aggregation and analysis. In addition, by using Health Check, the machine's condition can be assessed through regular vibration measurements.

Interlocuteurs

Oliver Hagenlocher

Zone

Press and Communication