Retrofit from EMAG: Energy Savings for Aging Machines

Modernizing old machines and reducing energy consumption in a targeted manner - this is how you could summarize EMAG's retrofit approach to sustainability. This delivers double the benefit to customers: significantly lower investment costs when purchasing the machine and reduced energy expenses during operation.

Enormous energy savings are possible

Enormous energy savings are possible, which is why the technical measures in the course of the retrofit pay for themselves after a short time. For example, EMAG regularly succeeds in reducing the total annual consumption of a running machine tool from around 104,000 kWh to around 86,000 kWh, resulting in around 6.7 tons less CO2 being emitted.

Intelligent management of machine processes

Various measures play a role here, such as:

- intelligent control of the hydraulic pressure via frequency converter and stand-by shutdown,

- a reduction in the coolant flow rate in standby mode

- as well as the cooling system for the machine and electrical cabinet using the cold water network.

Consume 30 percent less energy

In concrete terms, this means that the motor speed of the hydraulic pump is continuously adjusted to the optimum operating pressure depending on the load. As a result, the volume flow always "matches" the demand and the amount of energy required is reduced by 30 percent (compared to the storage charging system) - just one example of many.

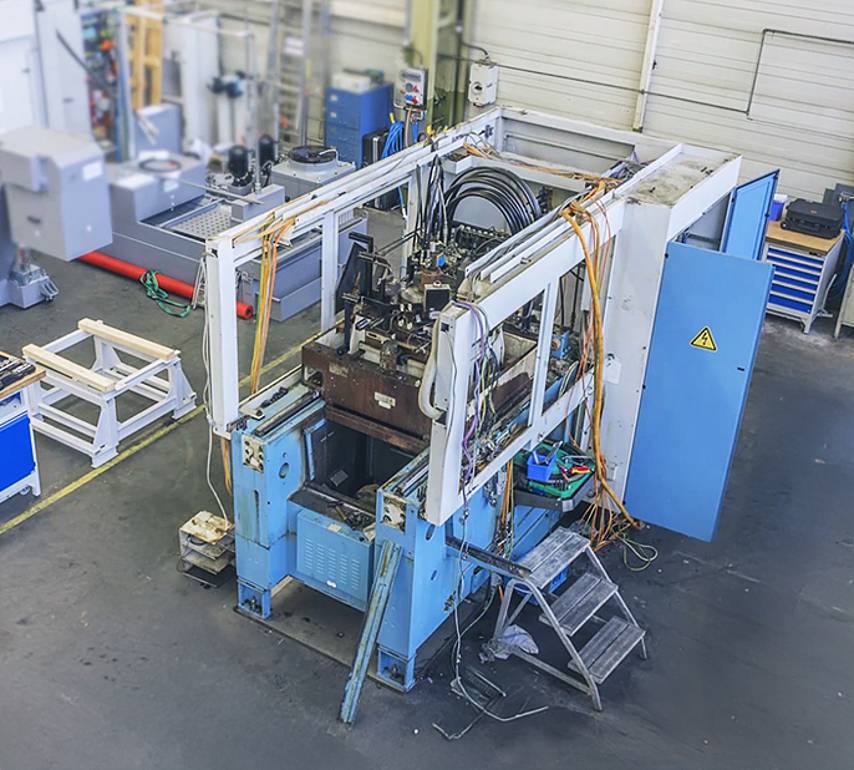

Reuse assemblies

In addition, every retrofit is an ideal way to continue using valuable materials over the long term. For example, the indestructible basic bodies of older (and initially no longer operational) machines are given a "second life." However, the rest of the machine is refurbished for the current task. Overall, EMAG promises the highest quality for all retrofit projects. The solutions have the performance of new machines - and their production is exceptionally sustainable.

Technical Hotline

Our technical hotline records all inquiries and gives you technical assistance

+49 7162 17-4300

service.salach@emag.com