MRC Robot Cell: Bin picking - the clever way to reach into the box

For a long time, the separation of raw-parts from the bulk material was only possible manually or using complex mechanical and usually very workpiece-specific solutions such as vibratory conveyors. The chaotic arrangement of the components prevented automated handling directly from the container.

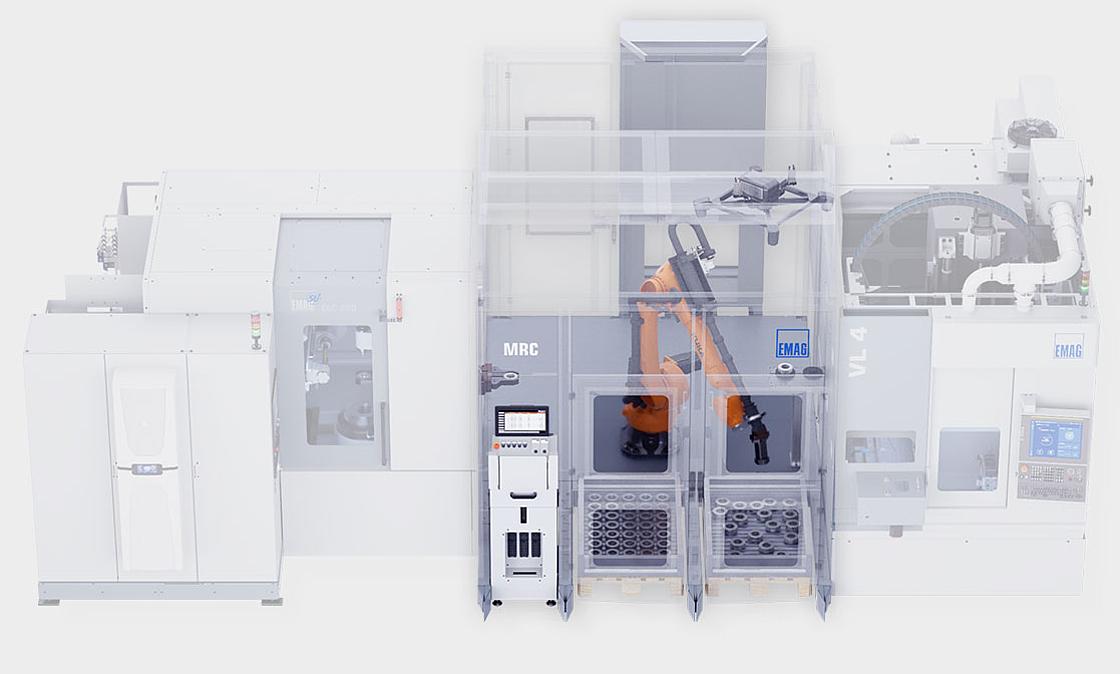

With the MRC robot cell, EMAG offers a modular automation platform for machine loading and link-up. Thanks to the optional bin-picking module, it can also be used to handle raw-parts in bulk efficiently and in a resource-saving manner.

MRC robot cell: Flexible automation for your production

The MRC robot cell from EMAG optimizes your manufacturing processes through its versatile application options. As a modular solution, it is primarily used for loading, unloading and link-up of machine tools. In addition, the MRC offers space for the integration of secondary processes such as buffering, deburring, blowing, measuring and marking.

Highlights of the MRC robot cell

- High flexibility: handling of different container types

- Bin picking: Efficient removal of raw-parts from bulk goods

- Modularity: Adaptable to individual requirements

- Platform-based: Crane and forklift-compatible for fast installation

- Universally applicable: Shorter project lead times

As a CE-compliant system from a single source, the MRC robot cell reduces administrative effort and simplifies servicing and maintenance. Our many years of expertise in machine tools and automation flow into every cell. The robot's 6-axis kinematics enable flexible layout design and precision handling.

The Bin Picking automation solution

The MRC robot cell offers advanced bin-picking functionality for maximum production efficiency. Using state-of-the-art camera technology and intelligent algorithms, the robot picks components from bulk containers with precision. This eliminates the need for manual pre-separation and significantly speeds up the production process. The flexible handling of different component geometries and sizes makes the MRC the ideal solution for a wide range of applications. By seamlessly integrating bin picking into the production process, the MRC robot cell optimizes the material flow and sustainably increases the productivity of the manufacturing systems.

Background to the MRC robot cells

MRC robot cells from EMAG are highly flexible automation solutions that are used in various areas of the manufacturing industry. Their main tasks can be summarized as follows:

Loading and unloading of machine tools

The primary function of MRC cells is the automated handling of workpieces. They take over the precision insertion of the raw-parts into the machine tools and the removal of the finished components, which leads to a significant increase in production efficiency.

Link-up of machine tools

MRC cells play a central role in the link-up of several processing steps. They transport workpieces between different machines and thus enable a smooth, automated production process.

Integration of secondary processes

A particular advantage of MRC robotic cells is their ability to integrate additional processes. These include:

- Buffering: Intermediate storage of workpieces to optimize the material flow

- Deburring: Post-processing to remove burrs and sharp edges

- Blowing off: Cleaning the workpieces from chips or coolant residues

- Measuring: Integrated quality control directly in production

- Marking: Application of product or batch markings

Advantages of MRC robot cells

Flexibility

Fast changeover between different component families, raw-parts and machining processes by using a robot with camera system and optional gripper quick-change systems.

Volume

Virtually noiseless picking up of components by the robot, no annoying noises due to mechanical separation.

Economic advantage

Reduced worker bindings for manual pre-alignment or other preliminary work on raw-parts and thus greater autonomy.

Integration

Simple integration of handling processes, such as aligning, cleaning or measuring components.