10.08.2020 - Press

Production system by EMAG: High-performance solutions for differential cases

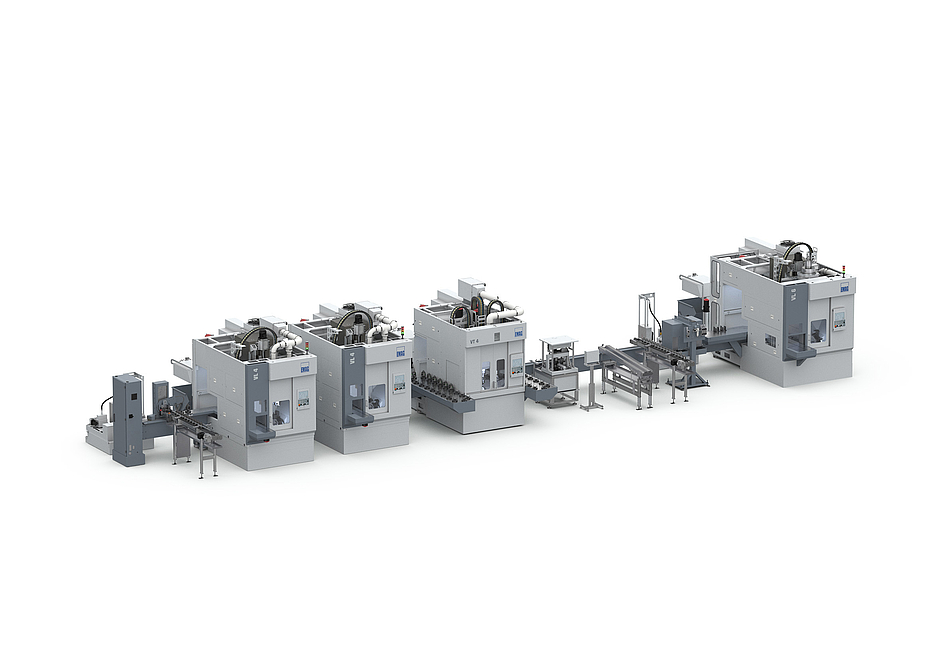

The worldwide production of motor vehicles is set to rise by about two percent every year until 2030, according to the estimates of a new McKinsey study. An excellent example of how to handle these rising production volumes despite stringent quality requirements can be found in the differential: This key component will remain indispensable whatever the propulsion system used by the vehicle. In other words, production volumes of differentials will continue to rise. At the same time, the machining required for parts like the differential case can be very demanding. The EMAG Group is well positioned in this environment: Its specialists develop complete production lines including vertical turning centers, automation solutions, and clamping devices. The user receives a turnkey, high-performance production solution for differential cases.

Imágenes

The differential case is still a constant focus of attention among production planners in the automotive industry. For one, it doesn't matter whether the vehicle is powered by a combustion engine, an electric motor, or a hybrid engine: They all require an axle differential that compensates the speed between the two wheels during turns. On top of that, there are different versions of the component that all need to be manufactured efficiently and reliably. Take the differential case, for example: There are closed cases with a spherical or hemispherical internal shape, and “open” cases with a lid. These shapes have an effect on the machining sequence. In all cases, however, a number of subprocesses are required which need to be carried out in a perfectly timed sequence cycle. Creating an overall system that can do this is a job for specialists—like the EMAG Group based in Salach, Germany. “We develop comprehensive solutions for machining different types of differential cases. EMAG supplies all the technology required, including vertical turning centers, clamping devices, and interlinking of machines. Customers discuss their requirements with a single point of contact and outsource the entire project planning to us. The result is a perfectly calibrated comprehensive system with short cycle times of only about 95 seconds, a small footprint, and high process reliability,” explains Daniele Loporchio, Technical Sales Manager Modular Solutions and technology expert for differential cases at EMAG.

Job done in four operations with a cycle time of only 95 seconds

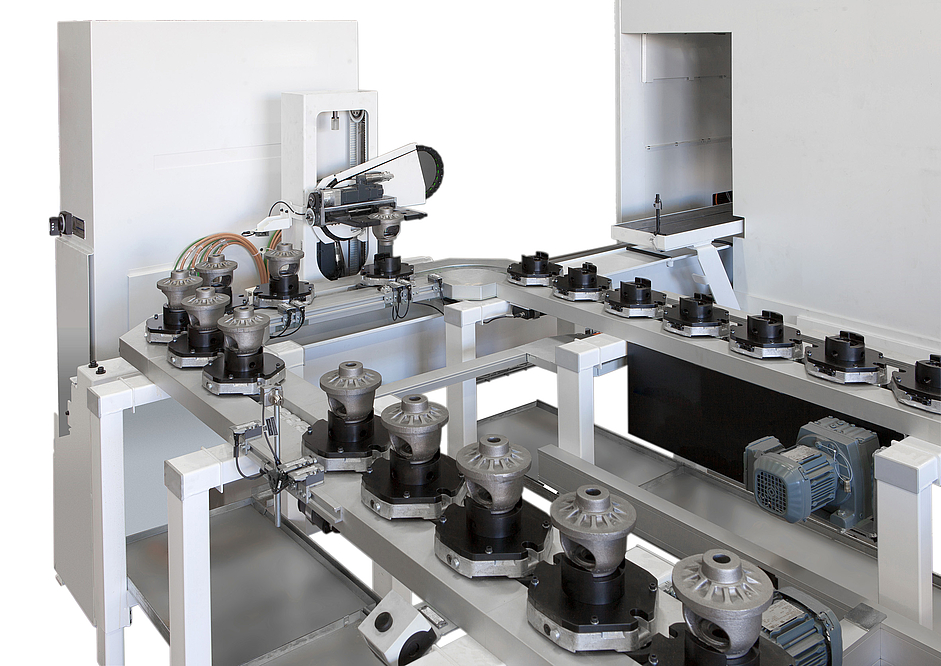

What is striking about the manufacturing system for differential cases that EMAG is presenting is its simple and yet ingenious design. To implement such comprehensive machining within a cycle time of only about 95 seconds, the machines used are exclusively based on EMAG Modular Solutions building blocks that are interlinked with the TrackMotion automation system.

OP 10 / OP 20: TURNING OF THE CASE SIDE / FLANGE SIDE

The case is first machined on two VL 4 turning centers. This is where the internal and external machining of the shaft mounts and flanges is performed. Furthermore, the driven tool turret with 12 tool posts on the VL machines enables them to drill cross holes.

OP 30: TURNING OF THE OUTER DIAMETER

The remaining external machining of the differential case is performed with a single clamping operation on a VT 4 turning center. This eliminates the occurrence of positioning errors when changing the clamping position. The VT 4 has two tool turrets with 11 tool posts each, which enables 4-axis simultaneous machining and thus quick processes. Moreover, parallel loading and unloading of components ensures short idle times.

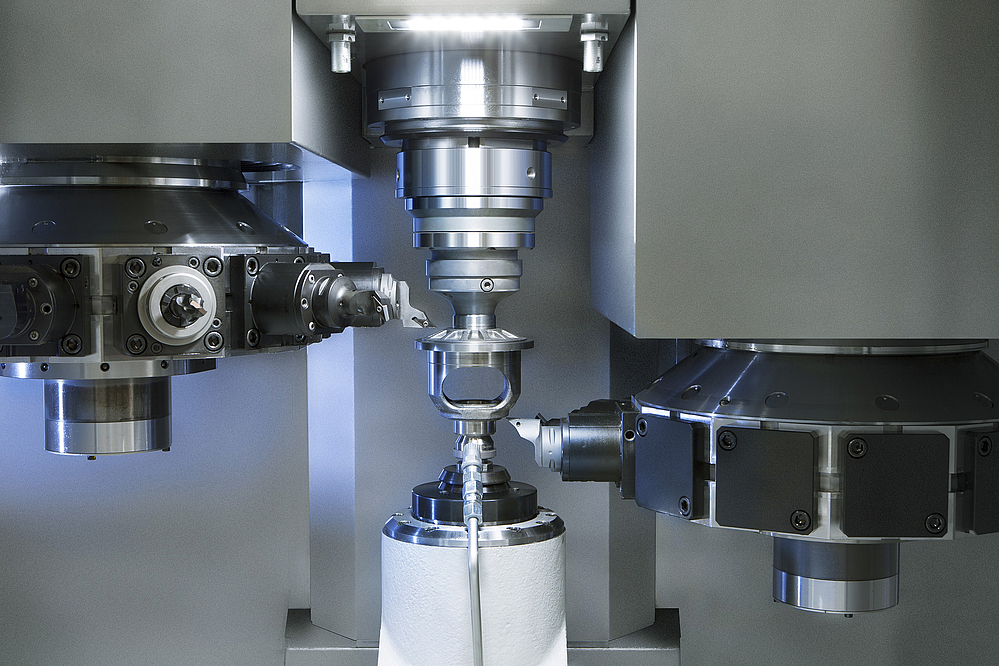

OP 40: FINE MACHINING AND FINISHING

Machining is then performed on a VL 6 pick-up turning center. In OP 40, the imposing clamping device catches the eye. It was specially developed by EMAG to machine differential cases (see image). In this operation, the bore holes are precision machined and the spherical calotte is first rough-machined on the inside with a special tool and then finished—all in a single clamping operation.

All that remains to be done now is final quality control. This is performed on an additional measuring system and thus guarantees that each differential case is of flawless quality.

The interlinking of the machines in this system is also especially effective. It is based on EMAG's modular, standardized machine platform: With their uniform transfer height, software control, and pick-up spindle, the machines can easily be connected using EMAG's TrackMotion automation system. A lifting and flip-over carriage with a programmable electric gripper runs back and forth between the machines on a track and places the differential cases on a conveyor belt. The pick-up working spindle then transports the parts in and out of the machining area, in a rapid process with little non-productive time. Owing to the compact vertical machines, the overall line has a very small footprint, and the modules can be accessed easily for setup.

Successful in the marketplace

In recent years, this slim and efficient approach has enjoyed ever greater success: 60 to 70 EMAG production lines with a total of around 250 turning machines are already in use around the world in the production of differential cases. OEMs and tier 1 suppliers rely on this technology. “We offer the complete package, from machine to clamping device. All the components are perfectly matched. Also, all our development work is grounded in a lot of practical experience. These advantages are gaining recognition in the marketplace,” says Loporchio in conclusion.