Noticias

14.11.2025 - Noticias

VSC 500 y VSC 500 DUO de EMAG: Perfeccionando los procesos de torneado en piezas grandes y pesadas para camionesEl mercado de vehículos comerciales está experimentando grandes cambios: se espera que en pocos años los sistemas de propulsión eléctricos a batería y de hidrógeno sustituyan parcialmente al motor de combustión tradicional, según los objetivos políticos.

Para ello, primero es necesario producir…

01.10.2025 - Oliver Hagenlocher - Historias de clientes

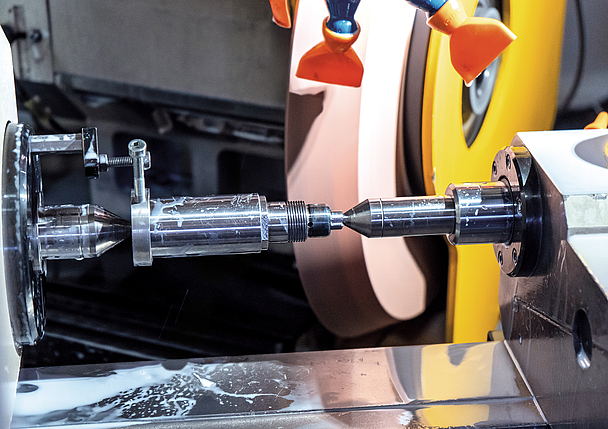

Rectificadora angular compacta mejora los procesos de producciónEn los últimos 50 años, Wandel CNC-Technik GmbH se ha convertido en un proveedor consolidado con su propia cartera de productos. La empresa familiar, dirigida ahora por la segunda generación, ha ampliado continuamente su espectro de producción: desde el fresado y el torneado hasta el rectificado.…

01.09.2025 - Oliver Hagenlocher - Noticias

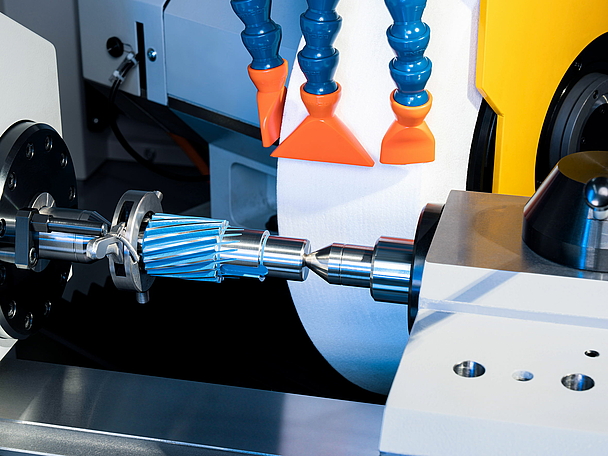

WPG 7 de EMAG Weiss: Garantiza procesos rápidos de Rectificado exterior en espacios mas reducidosEn muchos ámbitos de aplicación, no resulta rentable utilizar rectificadoras cilíndricas universales sobredimensionadas para el mecanizado exterior de componentes más pequeños: se pierde mucho espacio y no se aprovecha toda la funcionalidad. Con la nueva rectificadora exterior WPG 7, EMAG Weiss…

08.08.2025 - Oliver Hagenlocher - Noticias

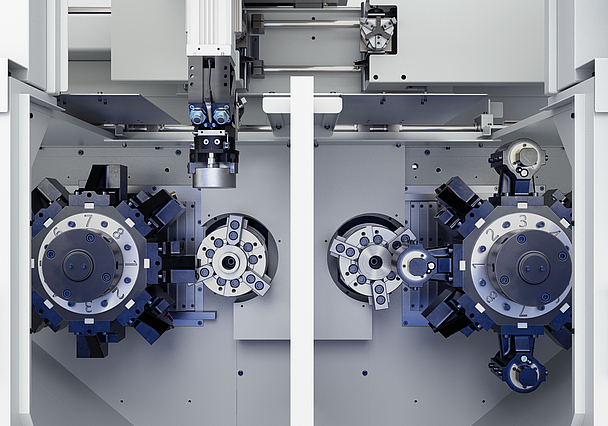

MSC 5 DUO: Centro de torneado CNC de carga frontal para un torneado suave económicoEn la manufactura actual, las empresas enfrentan retos importantes: aumento de costos, escasez de personal capacitado y alza en los precios de la energía. Esta combinación exige máquinas-herramienta que puedan ofrecer mayor producción con menos operadores, sin dejar de ser eficientes en el consumo…

30.06.2025 - Oliver Hagenlocher - Noticias

VLC 450 DG de EMAG: Perfeccionamiento del revestimiento duro de discos de freno en el proceso de rectificadoEl disco de freno del futuro para automóviles está recubierto: la única forma de cumplir con los límites de partículas establecidos por la norma Euro 7. Además, la superficie de frenado está protegida contra la corrosión y el desgaste. Pero, ¿qué proceso de fabricación puede garantizar que esta…

28.05.2025 - Oliver Hagenlocher - Historias de clientes

Amplia experiencia en mecanizado: Sistemas de máquinas EMAG VL en la cadena de fabricación de PENN GmbHEl creciente nivel de complejidad de los requisitos en el procesamiento de metales, junto con la presión internacional sobre los costos, representan desafíos particulares para las empresas manufactureras en países con altos salarios. La empresa austriaca PENN GmbH se ha consolidado como un…

07.03.2025 - Oliver Hagenlocher - Noticias

Revestimiento duro de discos de freno mediante soldadura por deposición láser: Revestimiento duro de discos de freno - y cumplimiento de la normativa EURO 7La norma EURO 7 cambiará radicalmente la industria del automóvil: Por primera vez, no sólo se regularán las emisiones de los motores de combustión, sino también la abrasión de los frenos, entre otras cosas. La conclusión inicial es que las partículas producidas por muchos modelos deben reducirse…

19.11.2024 - Oliver Hagenlocher - Historias de clientes

Precision manufacturing of high performance transmission components on vertical pick-up turning machinesZoerkler Gears GmbH & Co KG, a renowned manufacturer of high-precision drive systems for the aerospace and automotive industries, is using the VL 6 vertical pick-up turning machine from EMAG for machining high-precision transmission components. This strategic investment underlines Zoerkler's…