Complete Machining of Stator Housings for Electric Vehicles

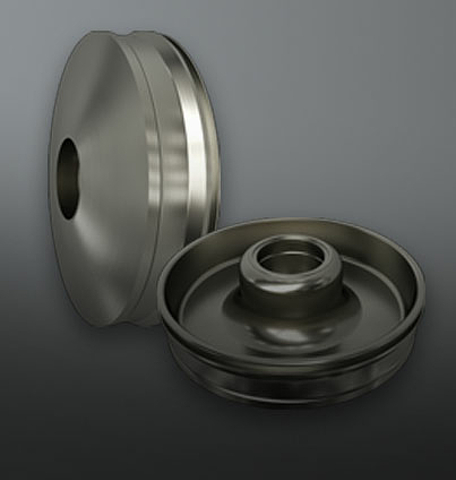

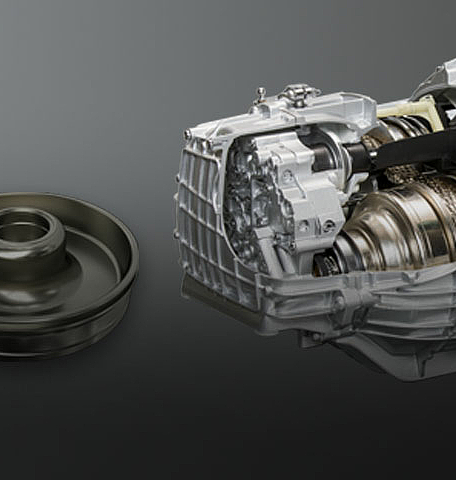

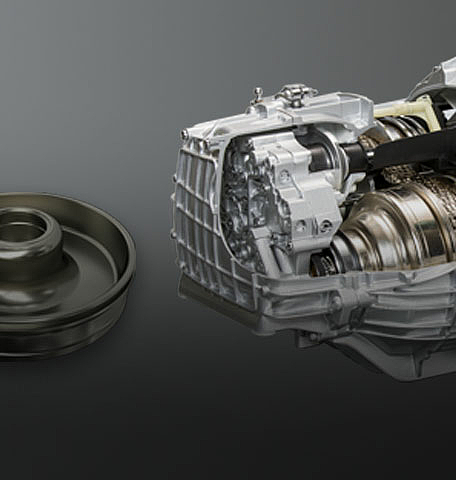

Our specialists at EMAG Scherer have developed a highly efficient solution for machining electric motor stator housings, allowing the complex and very thin-walled stator housings to be produced in large quantities with speed and precision in one or two operations, upstream or downstream of the machining center. This is accomplished by running two different operations in sequence on a DUO machine. Roughing and finishing of the outer geometry (OP 10) and roughing and finishing of the inner surface and connection surface, including some drilling and milling processes (OP 20), take place first.

The solution includes an NC-controlled rotary axis between the two work areas. With its help, the workpieces are deposited or turned in an oriented manner between OP 10 and OP 20. The cycle time for the stator housing is thus only 130 seconds, with both operations running in parallel on two components. Unwanted non-productive times are thus reduced to a minimum.

Watch this webinar (recorded) from our studio as our experts present the various possibilities.

Vídeos y descargas

Puede que también le interese ...

Registro en el Centro de Prensa