08/12/2019 - Oliver Hagenlocher - Press

The new MIND-L 1000 from EMAG eldec: Lower cost of investment and increased productivity in induction hardening

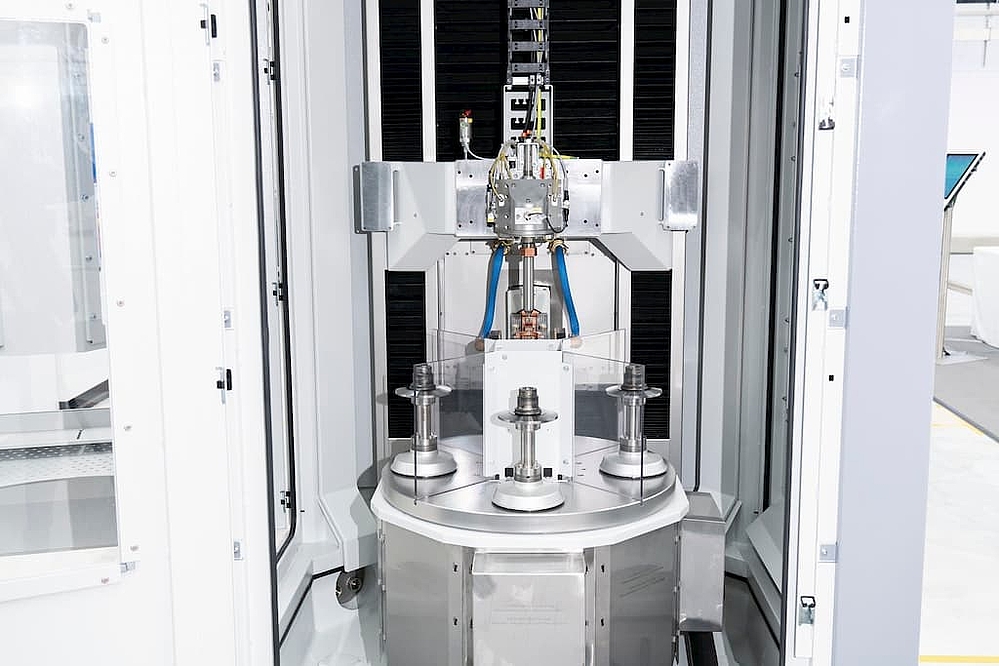

Precisely timed cycles, extremely accurate heating patterns and perfect integration in the production process—the advantages that induction hardening provides propel the implementation of the process in many application areas in the automotive industry: An increasing number of drive train, steering, transmission and engine components are induction hardened. Against this background, the newly developed MIND-L 1000 hardening machine from EMAG eldec comes at just the right time: The current generation of vertical rotary table machines handles high-precision hardening of shafts, transmission gears and the like in high volumes. With its modular design, the robust machine can be adapted to the respective production task, easily integrated into production lines or implemented as a standalone solution. Whatever the case may be, the cost of investment is lower, since the machine is more affordable than the previous generation.

Images

Automotive production means mass production: Key components, such as steering pinions, drive shafts, drive wheels, cam shafts, joints and PTO shafts, are produced by the millions at any single plant. The production process is perfectly timed and tailored to the component. For decades, EMAG eldec has been demonstrating how exactly this requirement is met in the area of hardening. As a company with operations around the world, the EMAG subsidiary headquartered in Dornstetten near Freudenstadt, Germany, produces and sells highly efficient modular induction hardening systems. With the new MIND-L 1000 it is now taking a decisive step, as Andreas Endmann, Head of Technology Sales for Hardening Systems at EMAG eldec, points out: “The machine replaces our proven MIND-750/1500 series. We’ve overhauled the previous technology in every detail, and we’ve improved its integrateability in EMAG production lines. For instance, an integrated gantry automation is available as an option for easy interlinking. Another important aspect is that the machine’s structural design has been fundamentally rethought—with a decisive effect: The price of the machine is lower than its predecessor without giving up on quality.” What’s more, the MIND-L 1000 generally stands out with an even higher precision and more rigid machine design for better repeatability in component quality and increased ease of maintenance. For instance, operators benefit from great access to the machining area during setup. A tool or clamping device change can be performed within the shortest time.

Mechanical engineering quality for greater precision

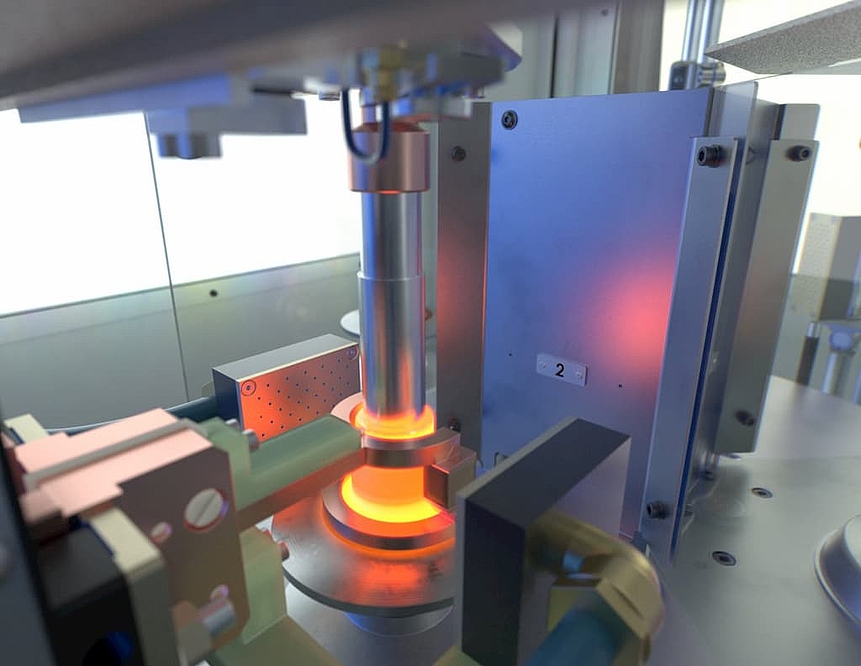

On the whole, with the MIND-L 1000, users thus get a highly efficient overall package for workpieces of up to 200 millimeters in diameter and a maximum length of 800 millimeters. The machine features X, Y and Z-axes to position the inductors, one or several C-axes for the various machining stations on the rotary table, up to five temperature and flow-monitored sprinkler heads for efficient quenching and safe clamping using a tailstock module with centering mandrel—all installed on a space-saving machine base. The precision of the hardening process is guaranteed by EMAG's standard design, since the machine base and many key components are manufactured at EMAG’s central production sites which makes them very rigid and stable. The MIND machines are then finished and “refined” at EMAG eldec. This is where the tools, as well as the coolant systems, clamping devices and energy sources are produced—robust low, medium, high and dual frequency generators with a power output of 10 to 3,000 kW are available. “We perfectly adapt all the components as well as the energy source to the component and to the desired heating pattern,” emphasizes Endmann. “As a result, the component is heated at auniform depth and temperature.” Furthermore, the extensive process data and machine condition monitoring that eldec Quality Control ensures the reliability of the induction hardening process—this is an essential factor when it comes to high-volume and interlinked production processes.

Integrated productivity gains

On this technological basis, the MIND-L 1000 guarantees that its users will benefit from tremendous productivity gains. Innovative drive and clamping solutions play a decisive role in this context. For example, rotary tables having four or eight stations are available—four different processes are performed simultaneously: loading and unloading in the first station, height check in the second, hardening in the third and annealing in the fourth. This means that machining and non-productive times are drastically reduced, which also makes it easier to integrate the machine in fast-paced production systems which, for example, the complete soft and hard machining of a component are performed in direct succession. From turning, drilling and milling to hardening all the way to grinding and laser welding, the EMAG Group has the required application know-how to develop a solution. EMAG also develops the corresponding automation systems. Currently, this expertise particularly comes apparent in electromobility, for example: EMAG has designed a line concept in which soft machining, hardening and hard machining are performed successively on a light rotor shaft. “We are ideally positioned for this and similar use cases with the MIND-L 1000,” concludes Endmann. “The machine is robust, precise and fast, can be precisely configured for any production task, can be integrated in lines or operated as a standalone solution. We’ve also considerably reduced the price. We are very confident that this approach will establish itself in the market.”

Downloads

Contact

Oliver Hagenlocher

Area

Press and Communication