12/01/2023 - Oliver Hagenlocher - Press

EMAG develops integrated solutions: Custom-fit robot solutions ensure fast parts flow in production

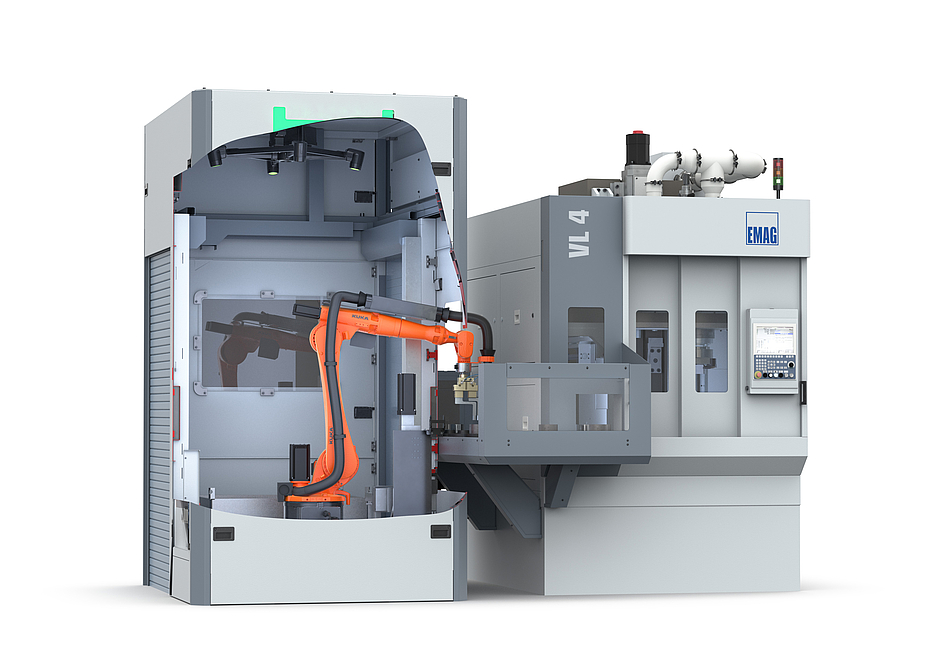

Production solutions with robotic automation are on the rise: With their help, a fast and low-manpower flow of parts can be established within a site – thus reducing unit production costs and increasing production reliability and quality. In this example, EMAG links pick-up machine technology with highly individual robot solutions designed within the requirements of the workpiece and the production process. What are important details?

Images

According to the "World Robotics 2022" report of the International Federation of Robotics (IFR), there are now around 3.5 million robots in use in industrial production worldwide. Europe is the second largest robot market in the world. Current examples from EMAG show why this is so: The specialists combine their high-performance machines with completely different robot cells - and thus not only ensure highly efficient processes for loading and unloading the machines, but also integrate additional stations for quality assurance, labeling, cleaning and much more. What is the overarching objective at EMAG when robots are used? "The focus is always on the requirements of the workpiece and the associated production process," explains Jürgen Maier, Head of the Business Unit Turning at EMAG. "Decisive questions here are, for example, what batch sizes are to be produced in a given period of time and how autonomously the solution should operate. In any case, we are very flexible and adapt in many ways to the existing production environment or space conditions."

With conveyors, palletizers or drawers

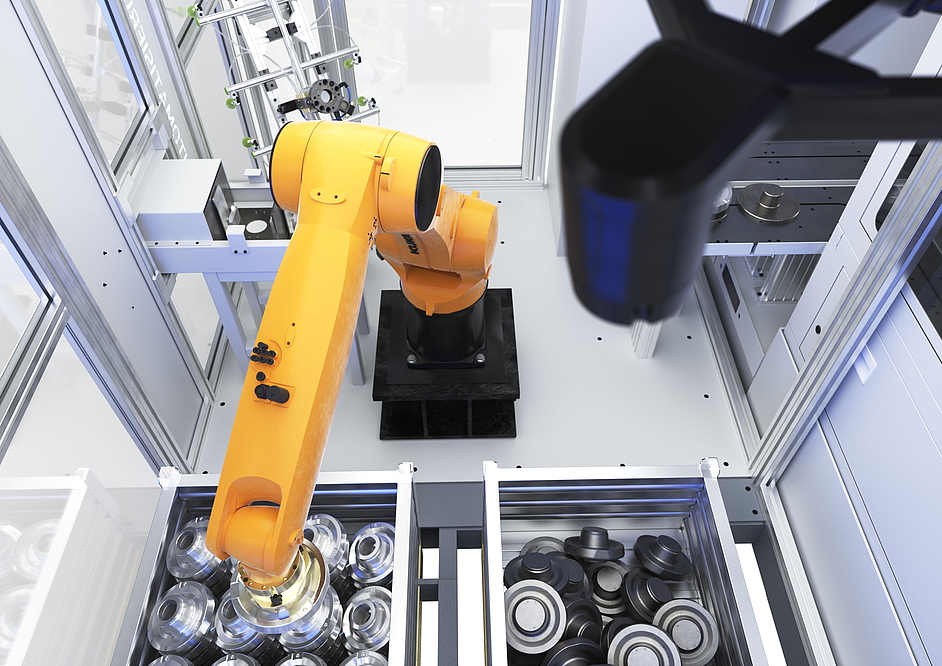

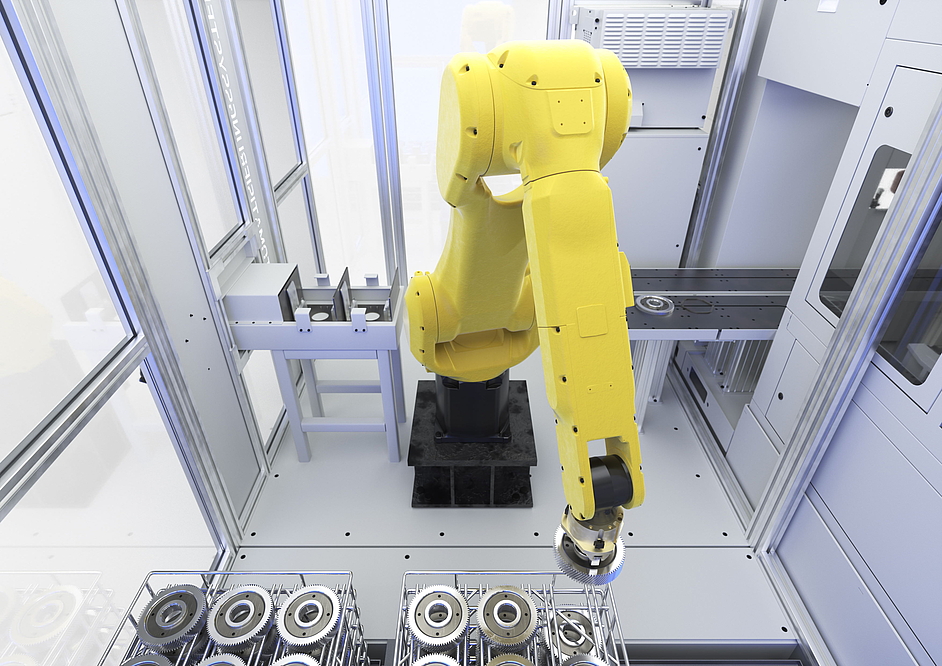

A look at the details shows just how different EMAG's robotic solutions are: Parts can be fed, for example, using infeed and outfeed belts, palletizers, drawers or bin picking. With the help of these systems, the robot "operates" itself when it picks up or finishes placing new components. Each solution has different strengths and basic conditions. For example, belt or hinge conveyors are an ideal option when the flow of parts needs to be smooth from an upstream production solution to the EMAG machine. The robot can then simply pick up the components from the belt and deposit them again later, with the belts arranged in different ways – depending on the space situation or the desired flow of parts. Pneumatic stoppers ensure that the components are separated. It is also possible to detect the workpiece alignment on the belt using a camera. A highly flexible alternative to this are so-called bin picking systems ("reach into the box"). Here, the workpieces are in a chaotic position, with the robot arm not only picking the components with the aid of a 3D sensor system, but also correctly recognizing and aligning them and feeding them to the next processing step. The system can be used flexibly and configured for many applications.

In contrast, the use of palletizers presupposes an "orderly" start. In this case, the system is loaded and unloaded via a blister cart, for example. It contains boxes stacked on top of each other with corresponding mold nests containing the components - i.e. a relatively large quantity per cart, which an operator simply pushes into a defined position from which the robot can access. The cart with finished parts is in a different position. "One of the things that matters in this kind of solution is that you relate the cycle time of the EMAG machine and the desired man-hours at the machine. So if the machining cycle within the machine is only a few seconds and at the same time you are aiming for minimum operator effort at the machine, this solution may not be suitable because the carriages would then have to be replaced too frequently. But these are precisely the calculations that we carry out for every robot solution and advise the customer accordingly," explains Maier.

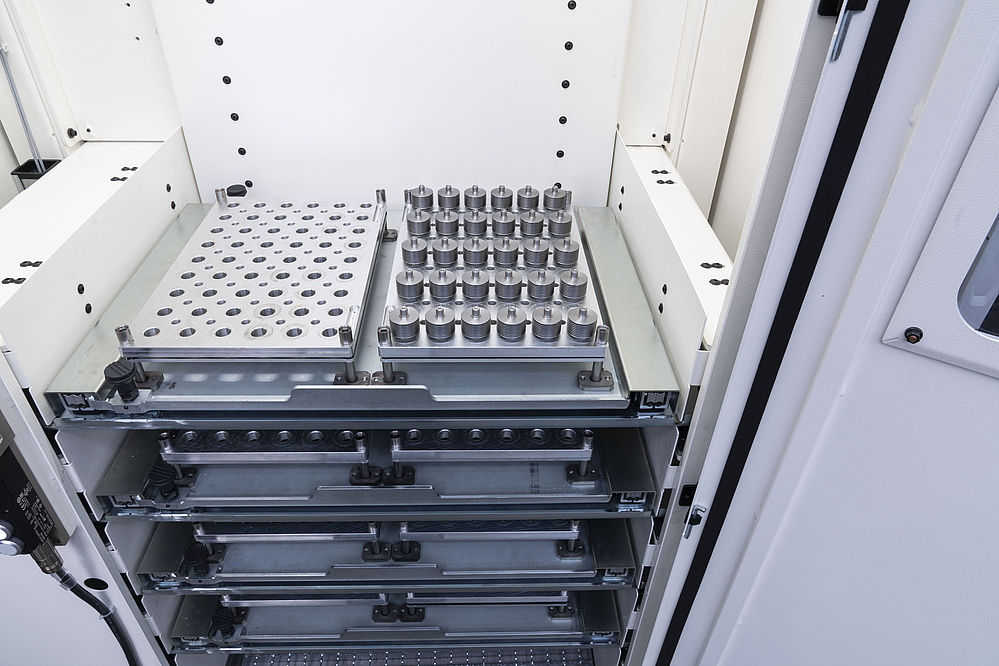

A drawer system is a conceivable third variant. The workpieces are located in pneumatically movable drawers, which are quickly loaded by blister systems. In this case, three of these drawers are arranged one above the other in a cabinet, allowing a larger number of pieces to be stacked and processed (without intermediate operator intervention) in a small (possible) footprint. Incidentally, loading and unloading of the drawers takes place without interrupting the process – the robot simply continues to work on a compartmentalized drawer.

Number of robot solutions from EMAG increases

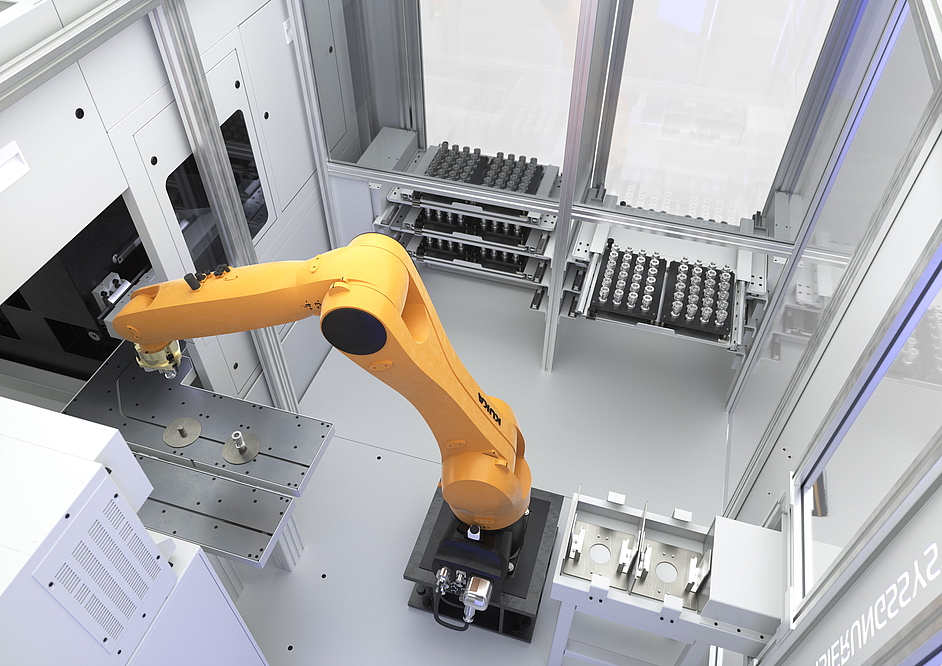

The following applies to all these solutions: The equipment options for the individual robotic cell are extensive. For example, it is conceivable to integrate a statistical process control (SPC) including a measuring station. Here, individual components are regularly ejected, measured and reintroduced for quality assurance. It is also possible to place optical control systems with cameras, a gripper station for processing a wide range of workpieces, small washing and cleaning stations, deburring systems or laser or engraving stations within the robot cell. The respective solution is then also controlled by the robot. The result is a continuous flow of parts across different technologies. For sustainable success with all customers, EMAG relies on computer-based simulations when planning automation cells. Our experts thus check many factors such as cycle time, accessibility of the robot, material flow in large production lines and much more. Virtual commissioning - that is, testing planning data on a virtual machine - is similarly important. In this way, unforeseen errors can be detected and eliminated at an early stage of development. What's more, "real" commissioning is much faster later on.

"Overall, it is safe to say that more and more robotic solutions are being used on our machines, although this is also obvious," summarizes Jürgen Maier. "After all, we have a large number of machines that already have internal automation based on pick-up technology. Consequently, we can integrate these solutions via robots into integrated production systems relatively easily and establish a smooth flow of parts at a single location. The components therefore get from A to B with little effort. This is our approach, which is winning over more and more customers."

Contact

Oliver Hagenlocher

Area

Press and Communication