12/14/2021 - Oliver Hagenlocher - Press

Electrochemical Machining from EMAG ECM: Electricity instead of drills and milling cutters: ECM as an alternative to metal cutting

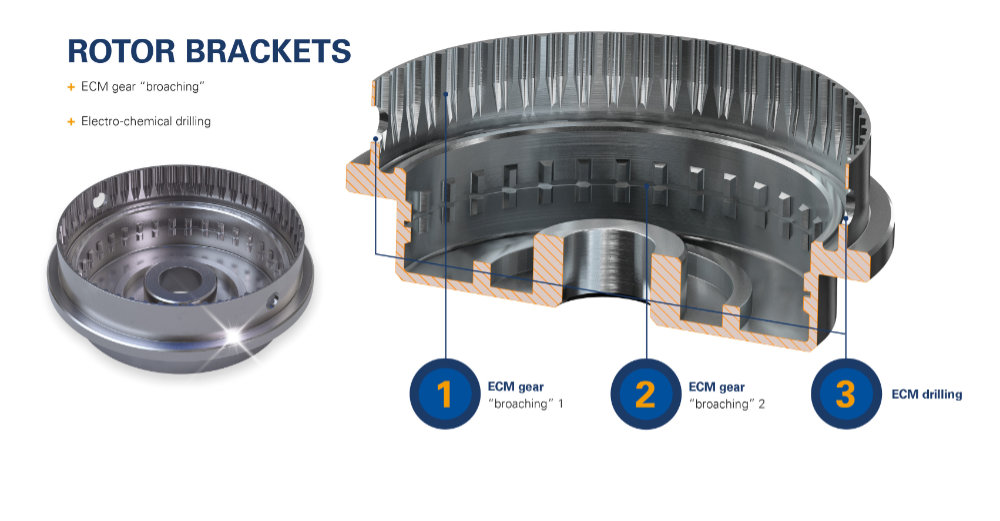

Electrochemical metal machining (ECM) is an established technique for burr removal. However, ECM can do much more. The EMAG ECM Company wants to use the process to replace conventional drilling, broaching and even milling. A number of advantages over machining speak in favor of this.

Images

"Structural change is in full swing and is also affecting the manufacturing industry," Franz Groß, Sales Manager at EMAG ECM in Heubach, is convinced. The advance of electromobility alone will reduce the total number of parts required in the long term. In addition, components would look different in the future. At the same time, the demands on materials, shape, complexity and precision are increasing. For example, more flow-optimized components are being developed based on examples from nature.

One answer to these challenges is electrochemical metal machining (ECM). It can now supplement or even replace conventional machining in many areas - with advantages for quality and economy. According to Groß, "The wear on the tool is much lower than with machining production processes, but the workpiece itself is also protected, since it is not subjected to mechanical and thermal stresses."

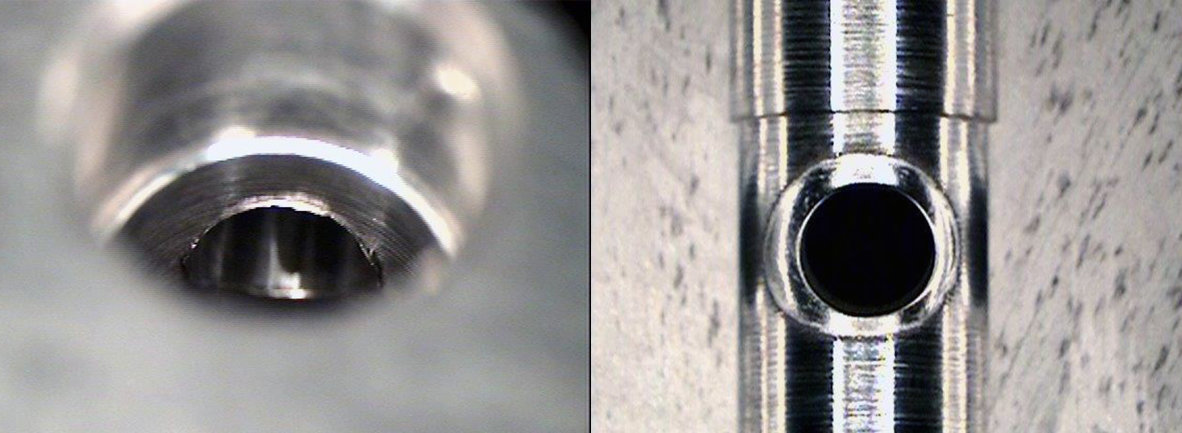

The tools are mostly made of the common stainless steels 1.4301 (X5CrNi18-10) or 1.4303 (X5CrNi18-10). On the one hand, they are particularly corrosion-resistant, but on the other hand, they can be machined well and do not need to be hardened. Depending on the material of the workpiece, surface finishes of up to Ra 0.5 micrometers and better are possible. This means that contours, ring channels, grooves or recesses can be produced with maximum precision without contact. "With a clever tool shape, hard-to-reach places can also be machined well and complicated shapes can even be realized inside the component," explains Groß.

Electrolysis forms the basis

ECM uses the physical-chemical process of electrolysis. Franz Groß explains how this works: "Tool and workpiece are in an electrolyte solution. A DC voltage with constant or pulsating current is applied to both. The tool forms the cathode and approaches a workpiece, the anode. A discharge occurs that dislodges material from the workpiece, which is carried away by the electrolyte solution."

Clean electrolyte flows in before each stroke. This is ensured by electrolyte management in a closed circuit. Powerful filters retrieve the removed material from the electrolyte, which is fed back into the process freshly cleaned. Groß: "Depending on the requirements, the electrolyte management forms an integral part in single-station machines or supplies several ECM modules as a separate component." Exchangeable cartridges, comb filter presses or microfiltration with backflushing are available for filtration. Automatic treatment keeps the pH in the neutral range. "The electrolyte should be changed once a year on average," the ECM expert recommends.

A detailed explanation of the ECM process, including a video, can be found here: https://www.emag.com/technologies/ecm-electro-chemical-machining.html

Material hardness does not matter

Depending on the machining purpose, different processes can be distinguished: For deburring and rounding of intersections, the use of a stationary tool is suitable. With the moving cathode, the tool moves into the workpiece at a constant feed rate, comparable to drilling and broaching. Precise Electro-Chemical Metal Machining (PECM) is available for three-dimensional machining, in which the tool has a negative shape of the workpiece to be produced. "In the PECM process, an oscillating motion is superimposed on the feed and pulse electronics, which ensures more precise tolerances with a significantly smaller working gap," says Groß.

Franz Groß adds, "Although the tool and workpiece never touch, we achieve feed rates of up to four millimeters per minute when broaching; for very filigree parts, it's still 0.2 millimeters." And this is practically independent of the material, "the only requirement is electrical conductivity." Unlike machining, the hardness of the material plays virtually no role in the process and process duration, he adds. "This also saves process steps because soft machining before hardening can be omitted."

Machines for every need

EMAG's CI and CS type machines are suitable for deburring and drilling. CI stands for Comfort Integrated and refers to machines with integrated electrolyte management. Groß says, "Two CI modules can also be combined to form the CI Duo, both of which then share the integrated electrolyte management system; this enables easy scalability of production capacities as well as entry into automation of the ECM process." CS refers to the standard variant, which is connected to a central electrolyte management system.

Premium Integrated (PI) is a modular machine platform for the PECM process and replaces machining broaching and machining. It is based on the CI with the corresponding compact dimensions. "The entire machine technology with electrolyte management and electrical engineering is accommodated on a basic frame suitable for forklift trucks and requires only 5.5 square meters of floor space," explains Groß.

The modular workspace can accommodate two different modules: the PECM module with oscillator or the ECM lowering module. Both can be used for simultaneous machining of several identical workpieces. Here, too, there is a standard version (PS) for the use of several machines that share a central electrolyte management system.

The machines are controlled by the widely used Siemens Simatik S7-1500 and Sinumerik 840D sl controllers with identical programming. Franz Groß: "For a new workpiece, all that needs to be done is to call up the appropriate stored type program and enter the relevant parameters."

The advantages of the ECM process at a glance

-

Low tool wear (cathode), thus good prerequisites for series production

-

Surface quality down to Ra 0.05 micrometer

-

Precise machining

-

No thermal and mechanical influence on the components and thus no changes in material properties

-

Hardness, toughness and magnetic properties are not changed

-

Production of small and thin-walled contours

-

Very high repeat accuracy of surface structuring

-

Simple and highly efficient manufacturing process, no rework such as deburring or polishing necessary

-

Roughing / finishing / polishing in one operation

-

Machining of superalloys

-

Simultaneous machining of macro and micro structures

About EMAG ECM

EMAG ECM GmbH, based in Heubach, Germany, is a technology company for the electrochemical metalworking sector within the EMAG Group. One focus is deburring in the machining process. As it is often overlooked during planning, this can affect the economic efficiency of the overall system. EMAG closes this gap and thus offers the entire machining process, including deburring, from a single source.

In addition, EMAG ECM has further developed the process in such a way that it can now be used instead of conventional machining drilling, broaching and machining. It offers solutions for the machining of extremely hard materials and the residue-free production of strategic components. ECM machines can be used, for example, to machine engine parts such as blisks much more productively than by machining. The range of products and services for electrochemical metalworking extends from consulting, development and prototype production to complete solutions.

Contact

Oliver Hagenlocher

Area

Press and Communication