White Paper: Customer Success Story - AccuRounds

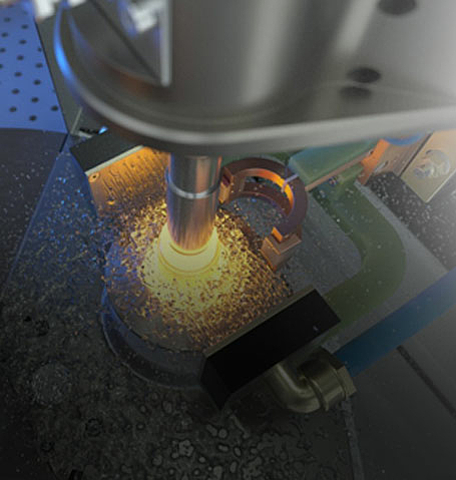

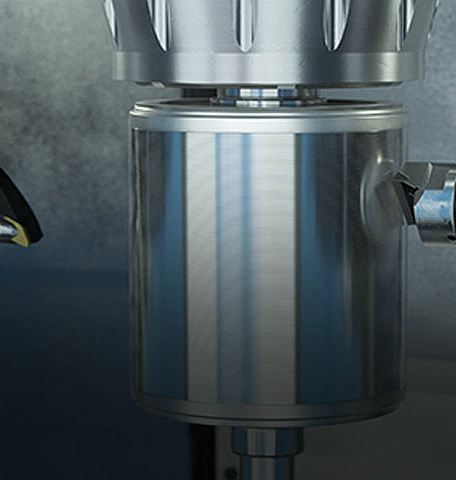

EMAG’s customer AccuRounds machines cylindrical components, often from difficult-to-machine alloys like Inconel, which has a high nickel content. AccuRounds’ relationship with EMAG began when they sought to solve a problem with chip evacuation during turning and milling processes. Increasing demand for precision components in the marketplace pushed them to purchase equipment with newer technology. In the end, they were convinced by EMAG's VL 2 and VL 3 DUO machines.

In this whitepaper you will learn why the company AccuRounds chose EMAG machines to increase tool life and to improve component quality.

Videos & downloads

You might also be interested in ...

Registration Media Center