GrindingHub 2024

Meet the EMAG Group at the GrindingHub 2024 in Stuttgart!

Date: May 14 to 17, 2024

Location: Stuttgart Exhibition Center, Hall 9, Stand C31

You can get free tickets with the code: "EMAGGRINDINGHUB2024" here: GrindingHub - Tickets & Opening times | VDW

We look forward to welcoming you to the leading trade fair for grinding technology, GrindingHub 2024. Discover our latest innovations and technologies in the field of grinding machines. Meet our experts in person and find out how our solutions can optimize your manufacturing processes.

Press Release:

Read the article about our trade fair presence here.

Brochures - Download the exhibit brochures here:

Product Summary of the EMAG Group

VLC 450 DG - Grinding of hard-coated brake discs

EMAG SU - Generating and profile grinding machines

EMAG Weiss Machine Portfolio

VTC 100 GT - Vertical turning and grinding in one machine

Our Exhibition Highlights:

G 160 Gear Generating Grinding Machine

The G 160 is a high-performance gear generating grinding machine. With an unprecedented chip-to-chip time of less than 2 seconds and an innovative axis concept designed for the highest precision in batch production, the G 160 offers enormous productivity. Ideally suited for machining in the module range from 1.0 to 5.0 mm, it can machine workpieces with a diameter of up to 160 mm and a length of up to 300 mm, making it the ideal solution for efficient large-scale production.

VLC 450 DG

The VLC 450 DG is a special machine for the high-precision grinding of hard-coated brake discs. This machine was developed with a focus on rigidity and durability to meet the high demands of batch production. The vertical design ensures optimum removal of the hard material particles and offers excellent accessibility for maintenance work. This makes the VLC 450 DG a reliable solution for brake disc production that meets the highest productivity levels and workpiece quality requirements.

VTC 100 GT

The VTC 100 GT is a multi-functional turning and grinding machine for the efficient machining of rotor shafts. It can be used to perform complex machining requirements such as hard turning and grinding in a single setup, which minimizes concentricity errors and significantly increases process efficiency.

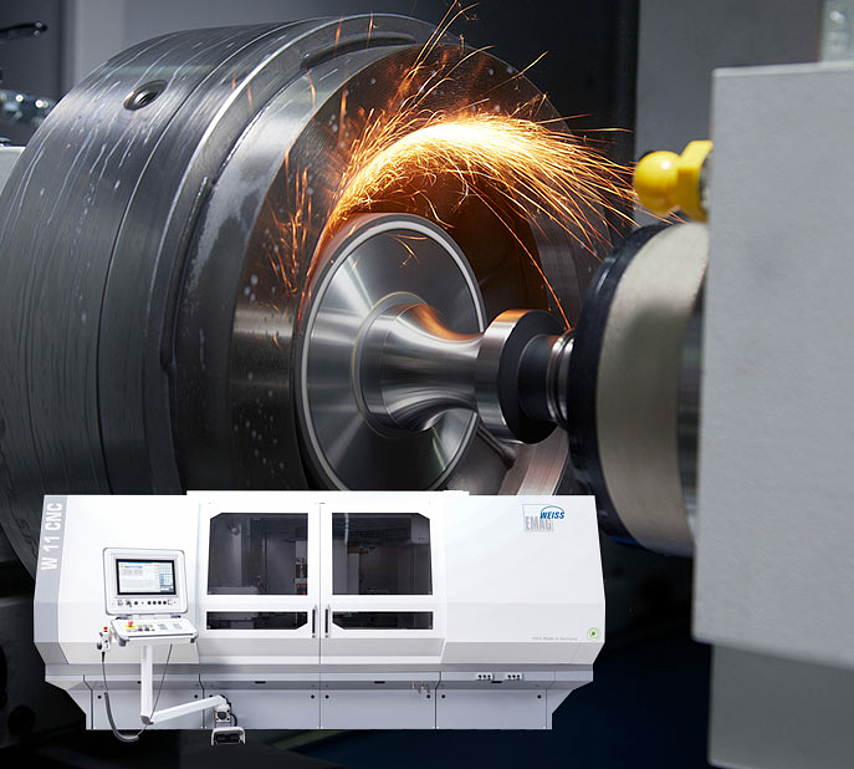

W 11 CNC

The W 11 CNC from EMAG Weiss is a high-precision CNC cylindrical grinding machine that has been specially developed to meet the requirements of contract manufacture, medical technology and general mechanical engineering. It enables external cylindrical grinding with maximum dimensional accuracy and cost-effectiveness, even for small batches or prototypes. The machine can be retooled quickly and easily, offering great flexibility for changing machining requirements.

W 11 EVO

The W 11 EVO from EMAG Weiss is a manual cylindrical grinding machine that combines traditional know-how with modern technology. It has been specially developed for demanding tasks in tool and mold making, maintenance staff or training facilities. The W 11 EVO combines manual precision with the possibility of using servo-electric axes for automated processes, making it a flexible and high-quality solution for specialized grinding tasks.

Come and visit us!

Experience our latest designs and developments live and see the performance and quality of our machines for yourself. We look forward to welcoming you to our stand in Hall 9, C31 and working with you to find the best solutions for your requirements.