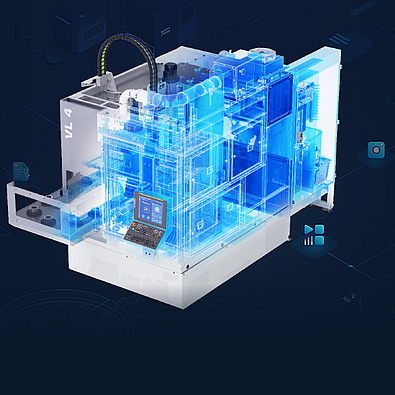

埃马克大修:为每项任务定制解决方案

适合未来的二手设备

凭借 25 年来成功实施改造项目所积累的知识,埃马克可使您的机床适应未来的需要。从根本上说,埃马克机床是任何大修的理想基础,因为其床身是由坚固的聚合物混凝土 Mineralit 制成的,在 "二手 "机床改造后可长期重复使用。

其他改造内容取决于用户的意愿:

整个改造过程包括:

- 对机床进行全面的机械和电气改造

- 集成附加刀具工艺或物联网技术

- 到小的改装,如集成一个新的夹紧油缸(或类似装置)。

此外,埃马克还经常收购旧机床,采用新技术对其进行升级,然后重新投放市场。因此,我们也可提供 "现货 "定制改造解决方案。

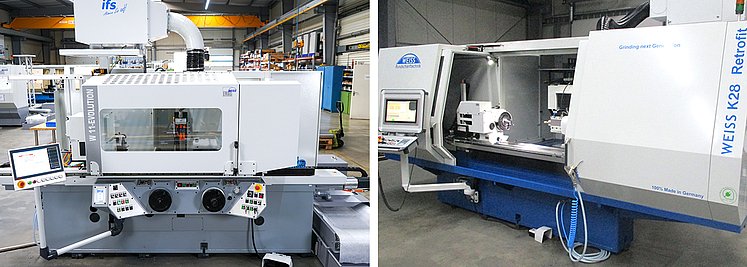

埃马克集团的磨床大修专业技术

埃马克还在磨削领域提供全面的专业知识,从外圆磨削到内圆磨削和非圆磨削。我们为埃马克和魏斯与卡斯滕斯的外圆磨床提供量身定制的现代化大修和翻新解决方案--从机械大修到全面技术升级。

可持续的数字化解决方案

此次大修在 "物联网 "和 "可持续发展 "等未来关键主题方面也很有意义。通过 EDNA,埃马克拥有了交钥匙物联网技术,可集成到更现代化的现有机床中(取决于所安装的控制系统)。

同样,"大修 "也能实现更高的可持续性:改造专家会分析现有的生产解决方案,找出不必要的 "能源消耗",并实施更经济的工艺。

![[Translate to Chinesisch:] Video_Retrofit_en](https://cdn.emag.com/fileadmin/_processed_/d/e/csm_Youtube_Thumbnails_VSC_250_Retrofit_--_1280_x_720_px_EN_79d4457ff9.jpg)

服务热线

服务热线记录所有查询,并通过电话或远程诊断为您提供解决问题的技术援助。

+86 512 5357 4098

service.china@emag.com