成形磨床

G 375 H

- Module range: mm 0.5 - 15.0

- 工件最大直径: 375 mm | 15 in

- 工件最大长度: 870 mm | 34.5 in

Precision Grinding for Gears, Worms, and Rotors

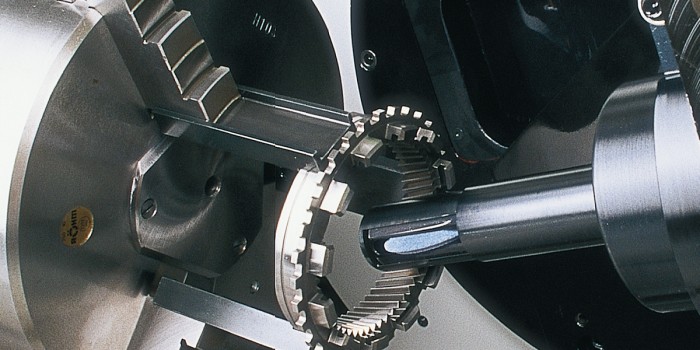

The horizontal gear grinding machine G 375 H is ideal for precision grinding high quality parts such as gears, worms, screws, and rotors.

Gear Profile Grinding Machine G 375 H

The G 375 H horizontal gear grinding machine delivers high-precision grinding for external and internal gears, worms, crown gears, rotors, screws and more. Designed for versatility and efficiency, this universal machine is the ultimate solution for manufacturers seeking top-quality gear grinding results.

Applications of the G 375 H Gear Grinding Machine

The G 375 H is engineered to handle a wide range of gear grinding tasks, making it suitable for:

- External and Internal Spur Gears

- Helical Gears and Crown Gears

- Worm Gears and Splines

- Ball Screws for Linear Motion Systems

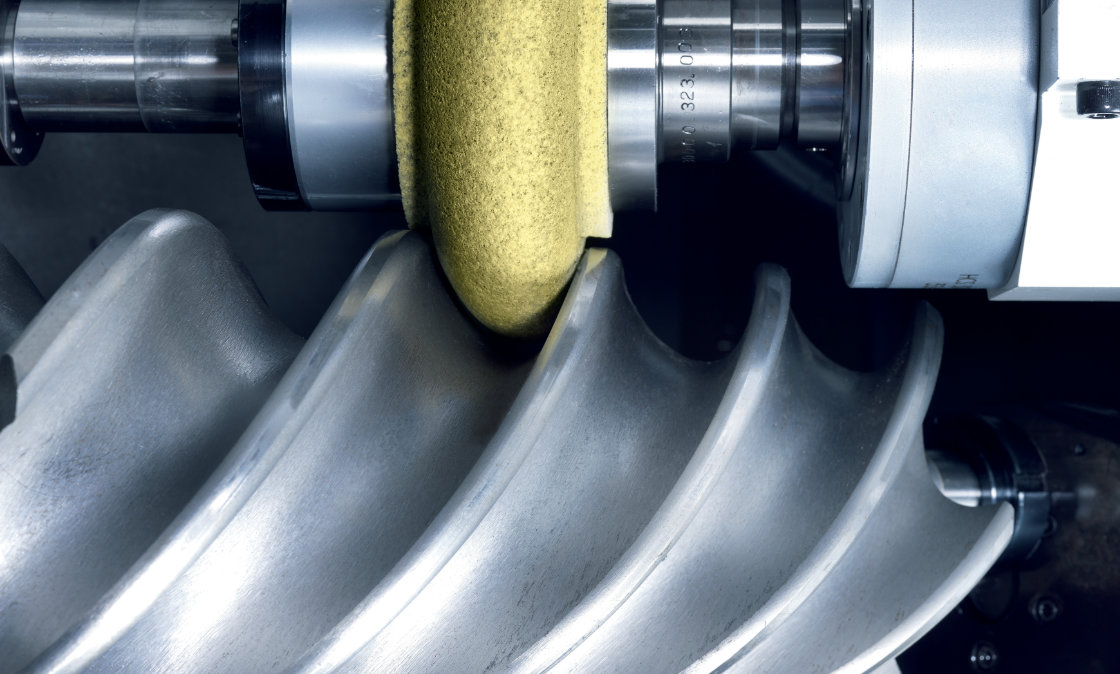

- Rotors for Air Compressors

- Screws for Hydraulic Pumps

This machine also supports the production of specialized profiles, such as asymmetric profiles and cycloid gears, using precise XY-coordinate inputs.

Enhance Productivity with the G 375 H

- Short Setup Times:

Maximize machine uptime with fast changeovers. - Integrated Gear Inspection:

Verify gear quality without additional processes. - High Flexibility:

Produce a wide range of profiles, including helical, spur and asymmetric designs.

Why Choose the G 375 H Horizontal Gear Grinding Machine?

The G 375 H offers the perfect balance of versatility, precision and efficiency, making it a top choice for manufacturers of gears, rotors and screws. With its modular design, advanced technology and exceptional accuracy, this machine adapts to your production needs while delivering consistent, high-quality results.

Ready to Revolutionize Your Gear Manufacturing Process?

Experience the precision and reliability of the G 375 H horizontal gear profile grinding machine from EMAG. Contact us today to learn how this machine can optimize your gear production processes.

优势 G 375 H

- High Stability and Precision: A rigid machine structure ensures a stable grinding process, with direct-drive and linear motors enhancing accuracy and reliability across all axes.

- Superior Product Quality: Delivers exceptional precision for gears and components, meeting tight tolerances and with integrated gear inspection.

- Versatile and Flexible Production: Handles components ranging from 30mm internal gears to large external gears, with quick transitions and minimal setup time.

- Easy Tool Changes: Simple and efficient tool changes allow for quick adjustments between different gear profiles and components.

- Customizable to Your Needs: A modular design supports tailored configurations and integrates seamlessly with automation systems for streamlined workflows.

工件

The Right Manufacturing Solution for Every Workpiece

工艺

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

技术数据

Module range

0.5 - 15.0 mm

工件最大直径

375 mm

15 in

工件最大长度

870 mm

34.5 in

| Module range | mm | 0.5 - 15.0 |

| 工件最大直径 |

mm

in |

375

15 |

| 工件最大长度 |

mm

in |

870

34.5 |

| Profile depth, max. |

mm

in |

35

1.5 |

| Centre dist. work spindle / tool spindle |

mm

in |

35

/ 340

1.5 / 13.5 |

| Tool spindle power |

kW

hp |

23

31 |