10/04/2021 - Oliver Hagenlocher - Press

Universal cylindrical grinders from EMAG Weiss – the right solutions for virtually every user.

The EMAG Group is breaking new ground with the universal cylindrical grinders from EMAG Weiss. The company from Salach, near Stuttgart, Germany, is mainly known for its (grinding) machines intended for high-volume production. But the machines from Weiss also offer interesting manufacturing solutions for users involved in the manufacture of smaller batch sizes or even just prototypes.

图片:

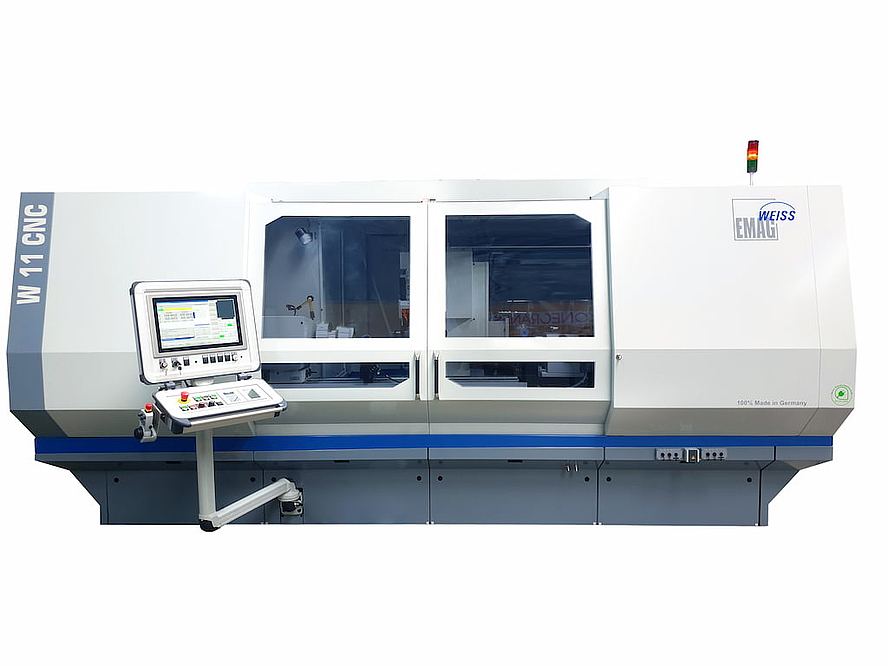

One of these machines is the W 11 CNC external-internal cylindrical grinder. Featuring an MK 4 to MK 6 spindle mount and a speed of up to 1,000 rpm, the machine’s workpiece headstock is naturally available with a great selection of clamping devices. This is matched by a foot switch-operated tailstock with an MK 4 tool socket that enables clamping of up 250 kg between the centers. The core of the machine is the grinding headstock on precision bearings with an output of up to 11 kW that can be fitted with grinding wheels up to 500 mm in diameter and 100 mm in width. Here again, there are a number of options available, such as control of the grinding wheel’s circumferential speed (Vc) or GAP control.

Moreover, the grinding headstock can be equipped with a continuously programmable B-axis, which further increases the machine’s versatility. The grinding spindle can thus, for example, be extended with an additional grinding head for external grinding or for internal grinding, which allows for quick machining of various grinding positions using different tools in a single clamping operation.

Optimization through automation of time-intensive processes

Grinding technology holds no mystery for EMAG Weiss and that’s why its experts know precisely which processes are not only time-consuming, but first and foremost suitable for automation, to make the actual grinding process as efficient as possible. One of these processes is dressing the grinding wheel, which is automated on the W 11 CNC. Once the diamond and workpiece are set, you can dress in full automatic mode, i.e., radii, bevels, cones and much more. The grinder then compensates the dressing amount fully automatically.

The machine’s control unit offers more advantages than dressing; for example, several diameters can be automatically ground in a single clamping operation. In path mode, the W 11 CNC also enables the grinding of tapers and contours. The automatic retraction of the grinding wheel to a safe changing position is only one of many convenient features that ensure fast tooling times.

Modern and fast control unit geared for grinding

Just like the whole machine, its modern control unit also is entirely designed for an optimal grinding process. Data entry and control are all done via a touchscreen. The machine can be programmed using an interactive interface or DIN ISO programming. Since all the software is based on Windows, data can be quickly shared with a desktop PC via a USB interface. Grinding programs can be written directly in the development department and then quickly and easily transferred to the machine. The standard version of the software contains all common grinding cycles. However, if required, a DXF converter, a geometry editor, and even programming of special custom grinding cycles by the experts at EMAG Weiss are also available.

Highly productive CNC external cylindrical grinder WPG7 with an extremely small footprint

The EMAG Weiss range also includes the brand-new WPG 7 for smaller workpieces like gear shafts, turbocharger shafts, or rotor shafts with lengths of up to 250 mm and diameters of 200 mm. It is designed for grinding wheel dimensions up to a maximum of 500 x 80 mm and has a variable grinding wheel circumferential speed of up to 50 m/s. The machine is available in the form of a 0° straight plunge or 30° angle plunge machine, with a workpiece headstock with stationary and rotating center MK4/MK5 or W20/W25 and a maximum speed of 2,000 rpm. The MK3 version has a tailstock with fine adjustment. The compact but powerful machine is designed as a “hook-up-and-install machine,” i.e., the control cabinet and peripheral equipment are integrated into the machine. This permits an extremely small footprint of 1.8 x 2.4 m. Quick and easy machine setup is made possible by outstanding accessibility and tried-and-tested cycle programming and completes the overall picture of the small but highly productive external cylindrical grinder.

下载

联系人