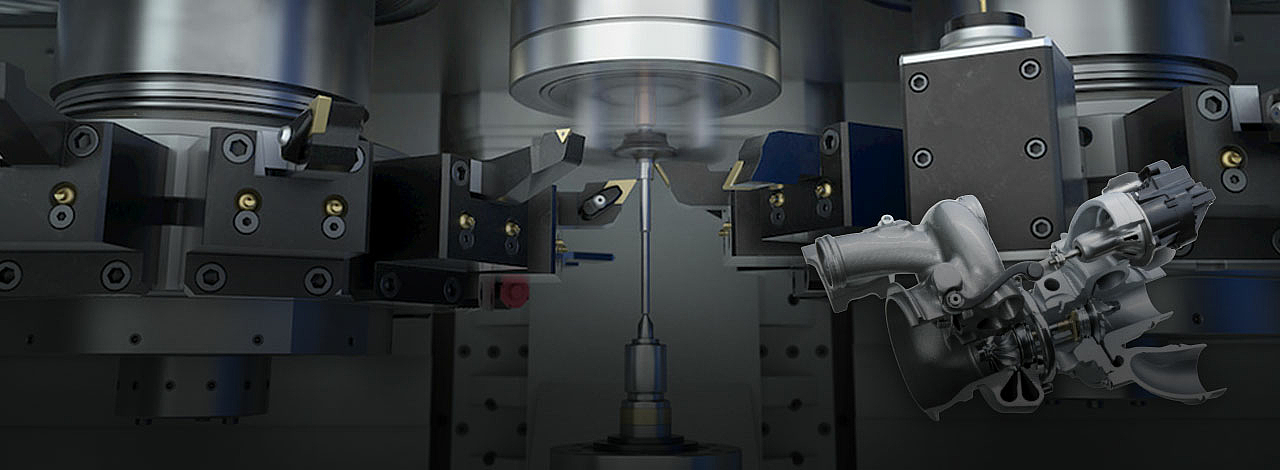

Turbochargers and E-Turbochargers – A Secret Weapon for Downsizing Engines

Turbochargers and E-Turbochargers – A Secret Weapon for Downsizing Engines. How to Produce the Components of this Power Part Cost-Effectively.

As part of the transformation in the automotive drive train, there is expected to be an increase in hybrid drives, with a simultaneous decrease in the number of pure combustion engines. Since there will be less installation space available for the combustion engine in the engine compartment of these hybrid models, it is necessary to downsize the overall size of the engine. A benefit of the downsizing is an overall reduction in fuel consumption, and therefore CO2 emissions – but there is concern about the impact on performance. However, with improved efficiency from the turbocharger, we can also assure users that the overall performance of the vehicle will not be impacted. For this reason, experts are predicting an increase in turbocharger production in coming years – which could be overwhelming for suppliers given the demanding production process. With our latest webinar, we will show you how we can help and exactly where you can start.

Focused specifically on the individual components for a turbocharger, we will show you in this recorded webinar what machining operations are possible with EMAG machines, and give examples of projects already in production. We will focus on the turbine rotor production process, and how we can create perfect manufacturing operations with EMAG’s broad technology portfolio.

Videos & downloads

You might also be interested in ...

Registration Media Center